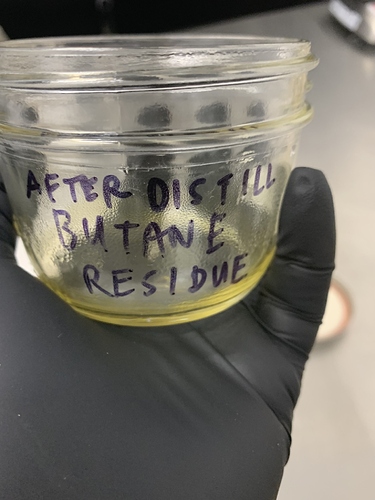

Instrument grade gas IS distilled, the dirty tanks your supplier keeps refilling are likely NOT.

Unless your supplier has Certificates of Decontamination or proof of decontaminate processing.

Have you ever refilled the same coffee mug a few times without dumping it out between refills?

You get some sediment right?

So what would happen if the coffee had NON DETECTABLE cancer causing BENZENE naturally and it became detectable after a few refills without cleanings?

BENZENE IN LPG (butane, propane and isobutane)

Liquefied Petroleum Gas ( propane ) , in its original state, contains radon and benzene , chemicals “know to the State of California to cause cancer.” … The benzene and toluene are destroyed when Propane is burned. Radon does not burn but is released with the combustion by-products.

Source: Benzene - WHO Guidelines for Indoor Air Quality: Selected Pollutants - NCBI Bookshelf

BENZENE AND CANCER RISK

What is benzene?

Benzene is a colorless, flammable liquid with a sweet odor. It evaporates quickly when exposed to air. Benzene is formed from natural processes, such as volcanoes and forest fires, but most exposure to benzene results from human activities.

Benzene is among the 20 most widely used chemicals in the United States. It is used mainly as a starting material in making other chemicals, including plastics, lubricants, rubbers, dyes, detergents, drugs, and pesticides. In the past it was also commonly used as an industrial solvent (a substance that can dissolve or extract other substances) and as a gasoline additive, but these uses have been greatly reduced in recent decades.

Source: Benzene and Cancer Risk

BTEX (benzene, toluene, ethylbenzene, and xylene) is present in natural gas streams and is being picked up in amine and glycol dehydration units, being present in the exit CO2 and Water streams. As a result, incineration temperatures need to be increased and hence the cost of compliance with EPA emission limits (25 Tons/year) is large. Specifically, in the presence of BTEX the appropriate temperature is 1500 °F, whereas when other organics (like methane) are present one can incinerate at 1350 °F.

Source: [PDF] BTEX Removal from Natural Gas Streams | Semantic Scholar

How do gas company’s remove BTEX contaminants from propane and butane?

Does anyone have a filter or method for removing BTEX from butane and propane? There are numerous water filters for benzene removal but I have not come across any methods for removal from gases or pressurized liquids. I tried a Donaldson clean LPG filter but after testing realized it filters down to half a micron and benzene is much much smaller than half a micron.

Source: https://www.google.com/amp/s/www.researchgate.net/post/How_do_gas_companys_remove_BTEX_contaminants_from_propane_and_butane/amp