Pretty much, hating on the product just to hate on it imo ![]()

Thank you.

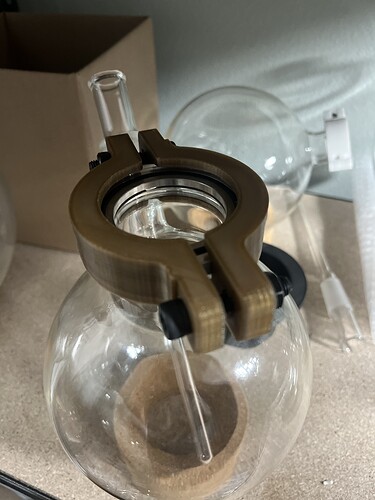

From the way he stated it it sounded like a low pressure clamp on a CLS or something

You’re absolutely correct that a clamp shouldn’t be necessary except for setup.

Once under vac there should be some 100 or so lbs of force holding it on there (~3” diameter).

Which would presumably make either the 3-d printed or the knuckle clamp a decent option…so long as you pull them before things get too warm.

It’s the “just asking for a wrench” clamps that make my skin crawl… simply replacing the nuts for knurled ones so it was clear that a wrench had no place in the operation would go a long way towards convincing me they were “specially designed “ for the task…springs and limiting threads so they could not actually BE over tightened would perhaps make them wook proof.

They could almost be viewed that way if you had a wook with a wrench (try to) solve an “insufficient vac” (say due to contaminated vac pump oil), by torquing down those clamps at 300um to “solve the leak”…

proper training goes a long way, but like I said those “wrench-able” nuts make my skin crawl

That’s a great point. If your only tool to solve vac problems is a wrench…

Think wook trained on (abandoned with) a large Chinese wiper…very similar looking clamps…I’ve seen folks snap them trying to achieve sealed.

Oh god. Here come the nightmares of wook techs unable to solve wiper vac issues

I see what you mean about risk of over-tightening with a tool. I can switch those bolts out for something less tempting for sure. Anything to mediate potential wookery.

For these clamps in the picture the part of the clamp in contact with glass is aluminum and is fairly loose fitting. I also have a high temp plastic option that seem to work okay at the temps this system operates but I’m still testing. This glass is thick and is barely under any force. I will be shocked when our first customer breaks a flange.

I’m going to send you a high temp clamp for your system. For your system we have a plastic option that is good up to 250C.

Color changing filament would be so sick for this application.

Who exactly banned this practice?

You should definitely let every roto-vap manufacturer on the planet know they’re doing it wrong. Sightglass manufacturers as well. ![]()

![]()

![]()

lol…gotta be a troll.

It is 100% a troll. We all know who it is and it’s pathetic that he spends his limited mental capacity doing this kind of thing.

id like the high temp version. love that you are always innovating

Hi I apologize I don’t recall the name you bought a system with. Did you buy a 5L kit?

Edit: that was meant to be a DM

Really love the systems! DO you find the stainless improves speed and/or lowers temperatures of your mains?

The steel does cool more easily but it also heats up more easily. As long as heat isn’t being rapidly wicked from the head, the steel works great.

The pictured system hits mains at about 170C. By 185C the system was running well over a liter an hour.

Is that THC ?

Can confirm that we measured around 1.3L/hr in mains. It’s crazy how much speed it picks up once it gets rolling.

Crazy how much the steel makes a difference, I’m super lucky to see similar numbers on my widebore 20L system. Glass just ain’t it for thermal retention lol