Hey have learned a lot about the various washing methods from his thread – appreciate everyone sharing the insights.

Wondering if anyone has experience retrofitting their devices to capture/stream data or be controlled remotely? What data would you even want to record in this scenario?

2 Likes

Why would you control it remotely? You still need someone to pull bags. Also what kinda data we talkin` here?

Legitimately curious, not trying to disrespect.

2 Likes

Honestly not too sure if there is any value from having remote operation… was thinking maybe like temp control/flow rate for continuous setups and RPM, but not sure that would be any faster than just changing on the fly while you’re pulling bags. Maybe if you’re running many large wash vessels with a small team?

Think there’s probably more value on the data streaming side of things. We’re working on software for hash makers to track washes, drying process, and pressing – we’re gearing up for a few connected device releases and curious what data you guys find the most useful to track (we want to avoid the rabbit hole of capturing/streaming pointless data just for the sake of displaying).

An obvious one to us has been utilizing how each head size performs during a wash to make recommendations about future batches, but think we can extend this to other forms of data (water temp, agitation rate, etc.) and anything else that you guys find valuable to track.

Thanks for reading the long comment… appreciate everyone’s insight

1 Like

Do you guys use a super chilled room for the Osprey or does it eliminate the need for a chilled room?

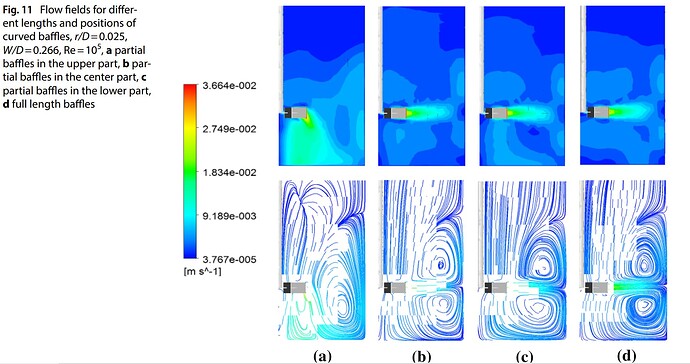

In looking at the available machines, I didn’t see anything with baffles (I could just suck at reading). I have been looking into flow patterns and found this information. If you place partial baffles at the top you can create a downward flow pattern. This would work well in a conical container if there was screen placed at the bottom, allowing the water to push the trichomes down towards the bottom and away from the buds. Is there anyone here that may have tried something similar and can tell me whether or not this is a solid thought or the idea of someone missing a lot of necessary information.

Baffles affect on fluid motion.pdf (2.8 MB)

This is the paper

2 Likes

@raghanded What was I saying

2 Likes

We had the same questions and did try baffles both physically and CFD. CFD predicted lots of shear which materialized in practice. Baffles did not provide any higher yields yet created shear and contaminants.

A customer had a fermenter with baffles added and ditched it for a Mesclatore. They tried baffles but unless you do the engineering right, it will not work well. And again, though they solve the vortex issue and improve the fluid dynamics, they create shear. Also, they tend to add cost especially when DIY and make cleaning harder.

What you can do to avoid vortex and skip baffles, is to offset the impeller from center and/or angle it to change the tank’s flow pattern. In many instances, this will create significant vibration which may damage the motor so won’t always work and a “sweet spot” is needed.

Here is our discussion on baffles:

16:18 Baffles

1 Like

I watched the video and he didn’t exactly address the various positions of baffles. Simply that most of them are full length which presents an issue. If the only problem is biomass interacting with the baffle, then having a partial baffle at the top would limit that interaction. The idea that you shouldn’t worry about microplastics because its going to happen anyway with bags and it happens with brutes was not a good argument for spending all this money on a plastic machine either. I did like the your system for catching the trichomes though.

Actually, the main issue with baffles is the shear and the fact they add cost and don’t help with yields. Why spend money to make an inferior product? That’s the point. Also, typically baffles are not positioned at the interface. This makes more sense in this case as baffles interact with floating biomass and create microparticles that appear in your hash.

As for baffles, the position, number, and size are relative to the vessel, process, and agitator. All 3 things are correlated and thus need to be designed accordingly.

As for system costs, our base system is $15,000 and can wash 40 pounds of fresh frozen per batch and 240+ pounds per shift. That’s pretty hard to beat on a food-grade industrial-sized system.

Some great resources on baffles and mixing in general are:

Mixing in the Process Industries by N. Harnby and M.F. Edward

Handbook of Industrial Mixing by Edward L. Paul, Victor A. Atiemo-Obeng, and Suzanne M. Kresta

If you don’t want to spend the money, here is another fantastic resource for the DIY.

4 Likes

I’d just like to take a second to say that every post or video of yours I see is highly educational, whether your system is the #1 or not it’s clear that you’ve put much love and care into developing it.

6 Likes

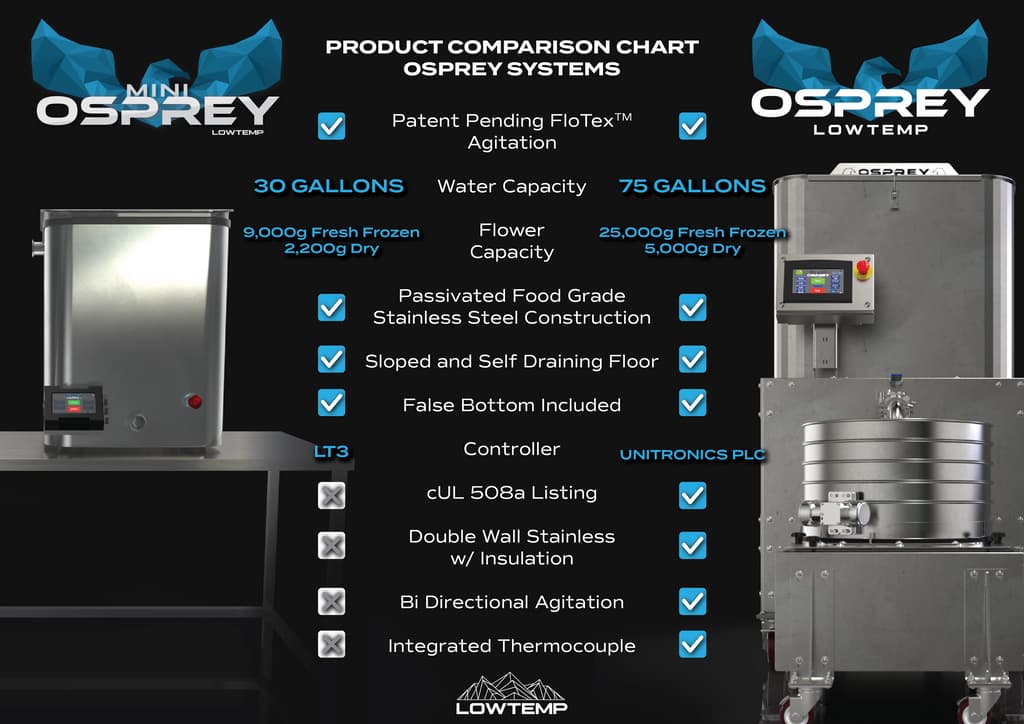

heard some mention of a mini osprey recently…

2 Likes

I saw it, looked nice. Had a little screen and whatnot. Hope they do well with it.

3 Likes

Are we talking 7% from FF to Bubble hash or 7% from FF to Rosin??

2 Likes

Solventless Systems @ MJBIZCON 2023

2 Likes

If anybody has an data logged around different wash vessels with yield #s and/or COAs, would love to help with analysis of those results at scale. DM me if interested in participating, we’re trying to create some objective numbers around the different agitation styles and setups.

1 Like

You lose bi-di going mini