Hello! We are just starting production on our automatic cartridge filling machines, and have 4 available at a reduced price. Check out the machine at vape-jet. com and contact us.

Just sent you an email.

Looking forward to learning more!

@AtomRoot1Botanicals Looking forward to connecting, I will get back with you later today.

How much?

I am asking $5000 for the first few units. This allows us to get our name out there and scale up. We do anticipate increasing the price once we are more well established.

For now, I can offer 15% off list for any orders through here. Use the code FUTURE4200

I am definitely interested in this unit. How much is the estimated loss from this unit? 5-10%?

and I would like to know how it would perform if it was ran for long periods of time.

Define loss. Besides the occasional drip while moving, we don’t have any loss in the system. Any fluid that is used to prime the pump is recoverable due to our use of a gas-tight syringe and valving system. Once the unit is done running and you want to recover what is left in the lines, you can go to the “Manual” page, click “Move to Catch Container” then cycle the pump a few times until you are fully recovered. You can also use this process for cleanup by running through your preferred solution.

Additionally, if you connect a syringe to the input side and press it by hand, the fluid will flow through the system without engaging the pump. This is great for cleanup and priming.

This is a project born of necessity, and is just getting started in the market. While I have a history of successful startups in the cannabis industry, there are no guarantees with any business that is just getting started that they will continue to be solvent. The current price is reflective of the risk customers are taking by purchasing a new to market system.

All the mechanical compoents in the system are shared with 3d printers and CNC machines, which are intended for 24/7 use. Design considerations were made understanding that these machines would be expected to be workhorses.

X / Y Axis - Heavy duty NEMA-23 motors connected to DN542T drivers on their own 24V power supply.

Pump - Lead-Screw driven by NEMA-17 motor driven by a TB6600.

Syringe - Hamilton Borosilicate / PTFE gas-tight 60mm stroke.

Plunger - 20KG Servo driven on seperate 6.2V supply.

Heater - PID Controlled 150W 12V heavy duty resistive heating element.

I will say that the demo machine has been running wonderfully for months while we have been developing the software, and we are offering a standard 1 year limited warranty with shared shipping expenses. (Maintenance / Consulting / Extended Warranty can be discussed, and deals worked out as we are just entering the market and looking for people willing to share their experiences.)

This is a project of passion, and I am very excited to finally be launching it. I firmly stand behind my product, and am willing to work with customers to ensure they are satisfied.

I love the machine vision feature you offer. What’s the approximate difference in throughput between operating the vision with foam trays vs your machined trays on non-vision?

Edit: oh and will your vision system hit the mark on the narrow fill gaps found on most popular glass/ metal carts, when still in the foam packing tray?

have any left at the 5000 tag?

Havent seen or heard anything since the inital posts

I ben checking out the machine how fast dose it fill 1000 1 g cartridges. Is it as simple as set up…insert cartridges block hit green button repeat ? Do i have to programme were the carts are ?

Any feedback in this tread from folks that used the machine?

Hello,Please email me and I will show you many more good solutions.lyn@lommachine.com

@BigHungryFarms - My apologies. To be honest, when I was trying to get some initial traction, after receiving a customer or two, it was all I could handle while I worked with those people to fine tune and launch the current business.

In the middle of all of that, Vape-Jet went from a one-man show to an entire team, moving out of my little home workshop into a full facility with machining capabilities. It has been a wild ride, and I am finally able to let my new team take over the day to day operations, and focus more on getting the word out and reaching out for new customers.

The fill rate is entirely dependent on viscosity and temperature, but you can expect anywhere from 400 to just over 1000 per hour, per machine. The dispense path is N2 assisted, with a mechanical ceramic valve, so you are able to push extremely thick fluids at much lower temps than any other fillers.

The software has been massively upgraded since the initial post. And we just released the ability to fill pod style carts as well ![]()

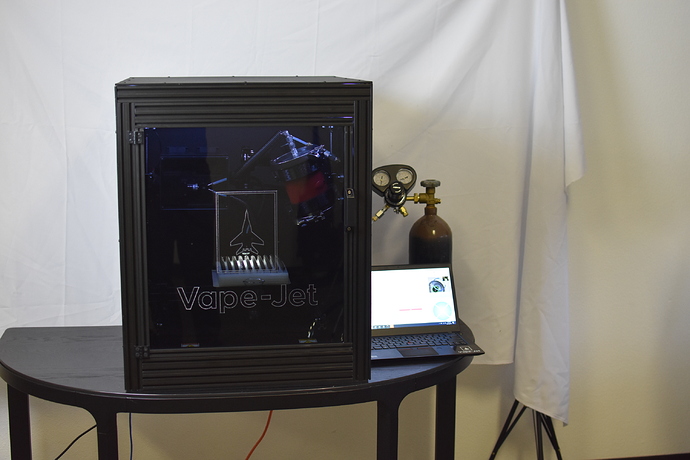

One of the really cool things about our machine is the ability to provide virtual demonstrations. Because the system comes with multiple cameras that are constantly streamed to the GUI, we can let you access our demo machine and play with a system in real-time and stream the entire process.

Again, as above… Sorry about the late reply ![]() I reached capacity and didn’t have any time except to serve my existing customers while focusing on expansion.

I reached capacity and didn’t have any time except to serve my existing customers while focusing on expansion.

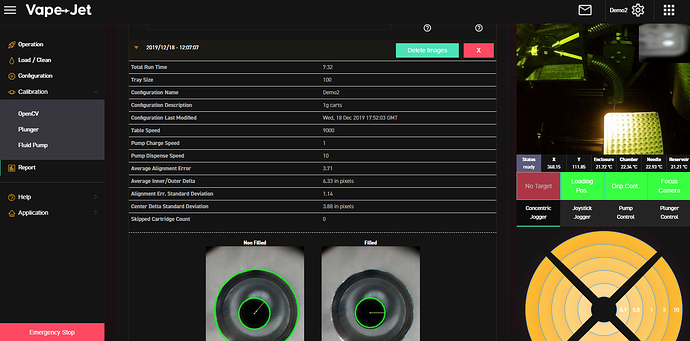

We actually measure the offset between the inner post and outer wall of the cartridge, this process is done while aligning the machine, which is performed entirely in the time it take the pump to recharge between individual fills.

Based on that measurement, we calculate the optimal angle to place the injector needle, and insert the needle in that exact location. You can see a visual representation of that angle in the above screen shot of the GUI. Look at the “Non Filled” photo and notice the offsets between the two circles, the yellow line points to the angle where we insert the needle. The distance is also calculated by the machine.

I hit capacity at what I was able to handle as a one-man-show. I spent the past 6 months building a great team and refining the design. I hope you give us another look!