so you searched?!?

Biomass Grinding at various scales?

Beating the "shred" horse

yes, there are LOTS of options. from leaf vacs to dedicated cannamills.

some folks have used plastic shredders successfully. eg @Lincoln20XX and @thesk8nmidget have both mentioned success there. pretty sure @Lincoln20XX built his from the open source version. @thesk8nmidget picked up a larger one used.

there is absolutely a difference in the required tooling between “hemp” and high THC biomass.

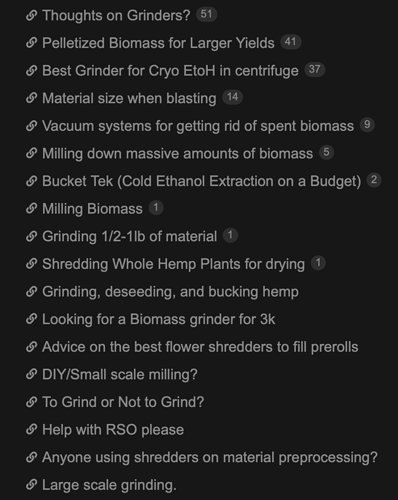

pro tip: check the cross-links after the first post. eg these are all linked from

Biomass Grinding at various scales?