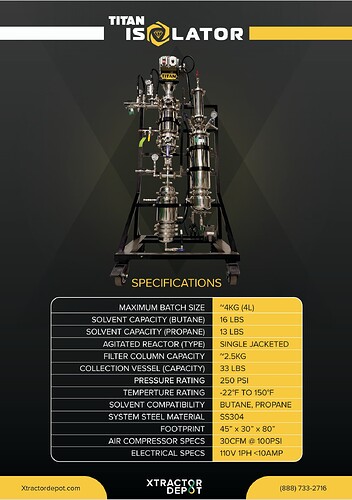

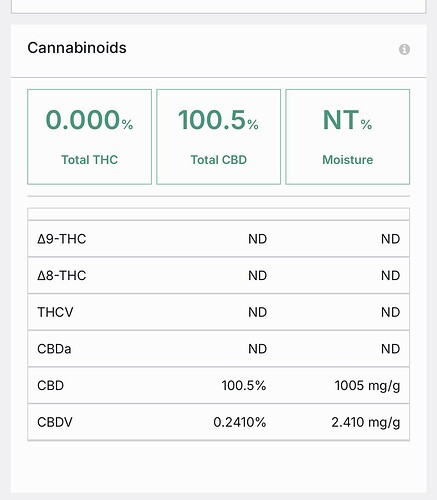

Here’s a couple of spec sheets for our 4 Liter and 8 Liter Isolators. Due to current demand, wait time is up to 8 weeks from the time of payment to the time of shipping. When comparing prices, make sure to check that the peer review, training, and support is included. Our Isolator, combined with our training and SOP will have you cranking out 98-99% thca reliably, day in and day out.

Unfortunately the lead time is too long

Price is too high

Doesn’t work well with my process. We aren’t doing thca.

I appreciate the feedback, and look forward to an update on you upcoming new set up!

For sure. You guys are killing it…. Love the setup for sure and love the communication from you guys. -^

oh man i think if you have to use that..youre not doing reacting right.

This thread is a rollercoaster!

my point was if you have to bust up your isolate, you can adjust your process to pull it out slightly wet and finish off so its easier. no more working out… its like using your brain to save your muscles.

not that you make bad product…but that your process can be improved. You will learn these things if you ever attempt to scale up.

youre telling me! I still suggest chemtek or xtractor depot. both seem solid, chemtek just couldnt communicate to the speed I need on this project. China was faster.

Check out Rosin Reactor. Small, highly customizable, and excellent for bench scale RnD.

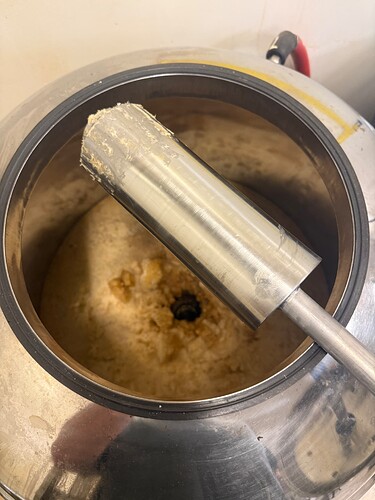

the workout is in lifting the “crystal breaker” which is more so the stopper/drain plug of the reactor. The crystal breaker does not break any crystals. The workout is that it is a manual actuated, not air driven so you need to stand on top of the unit to get leverage to lift it. (Ole Twist & pull)

You are suggesting I should just push out slush?

To a secondary filter?

I’d love to hear suggestions for improving.

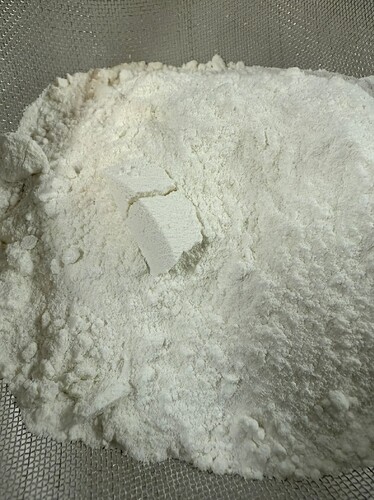

Currently i isolate>wash>crush>vac oven> crush

I only work with CBD and CBG so I have no idea how any thca crystallization goes. So I do harvest and crush the isolate, however that imo is not a workout or difficult, compared to lifting the drain plug/crystal breaker. (My crystals tend to trap solvent/id rather ensure they are nd so I melt and purge)

I probably should have used italics in my original post, I thought it was pretty clearly a joke.

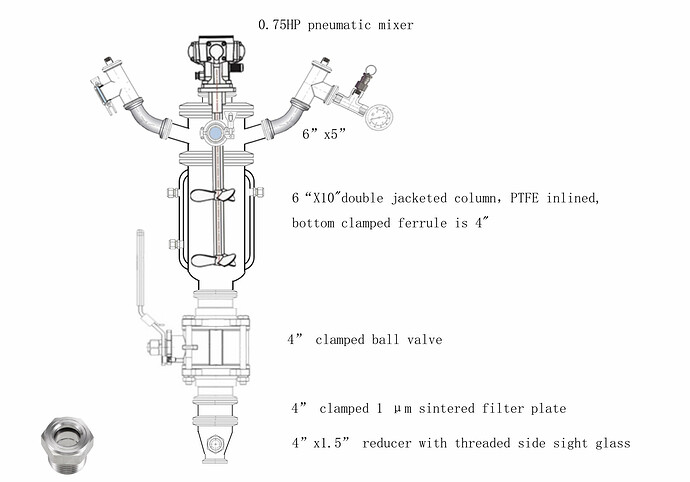

These systems have a sintered disc at the bottom of the reactor. lets you pull off all the mother liquor and wash if you need.

If you have big bucks get one of these and refine your crystallization process like a pharma company. Not useful for butane and propane, but great for other solvent systems.

Same. The disc filter is what the crystal breaker plugs up. the only time it clogs is running slush/sand due to saturation or crashing etc. so is why I asked when you recommend to run slightly wet so I could step my game up.

I was thinking maybe you were suggesting to push out everything into a filter skid.

But yeah, I do exactly what you just described.

@danklestein usually I do a 10kg sample batch on new material. But it could be cool to scale it down even more.

I would for sure run everything a little wet. push it out. the chemtek unit is a sweet little baby machine. those guys are working hard but couldnt deliver in time for me so i just hired it out to china for a whopping $3300

Chiller talk time…

Koray doesnt do cash payments anymore so ill find another brand. thinking of picking up a 50/30 locally to do some testing from -10 to -30

What temps are you folk running for thca and what times are you seeing for full crystallization

we run a G&D 7H. our system isn’t huge. -20 is usually our sweet spot. crystallization time depends on the material of course.

anywhere from a couple of hours to 6-8 hours for stubborn batches (usually lower grade/older material).

apparently, there is a new seeding attachment that we plan to add soon that will reduce crystallization times to under 2 hours. but we don’t have that yet.