Title says s it all

Have a 16 kw -20C chiller not sure what kw cooling power it has at -20 C

But technically it should work if the coil is long enough and the receiving tank well jacketed

Running a shotgun condenser/coils on a -20c to aid recovery is pretty common, but it’s going to be slow if you’re relying on that for the entire process.

We were running a -30c AI chiller passive, realistically it would maintain -14 to -21c during runs, but it took about 90 minutes to recover 70lbs at 33c

Iefff that slow pfff

Was afraid of that

Yessir was absolutely brutal. Ended up going to 1.5" bellows to a haskel and now we get about 2 lbs a minute.

Yeah, I use a Huber CS 200 with a jacketed tank from extractor depo with a tube and shell

I run it at -16 it works pretty good towards the end I pull a bit of a vacuum on the tank. It won’t go super deep but deep enough to finish it off.

Use a PIAB pneumatic vac pump to keep pulling vac on solvent tank. Speeds everything wayyyyyyy up when you aren’t fighting head pressure on the solvent storage tanks.

Make sure to vent exhaust outside

This is a Huber CS 100 on a shotgun condenser towards the end of recovery. If you’re able to pull vac on the tank with a venturi pump, you could get decent speeds. This is when it’s happy and maintaining -15c to -20c. In the summer, when the ambient temps are up, it might go up to 5c by the end of the day. At that point, you’re no longer seeing liquid butane in the sight glass, and it’s only slightly helping the main condenser. This can obviously be solved by keeping the chiller at proper ambient temps, but it’s something to consider.

You can use a water cooled chiller in this situation, too, but that would require a chiller to chill your chiller. Usually a glycol outdoor rated chiller so you dont fill your lab with heat aswell.

The condensation temp is based on its pressure… higher pressure = higher condensation temp.

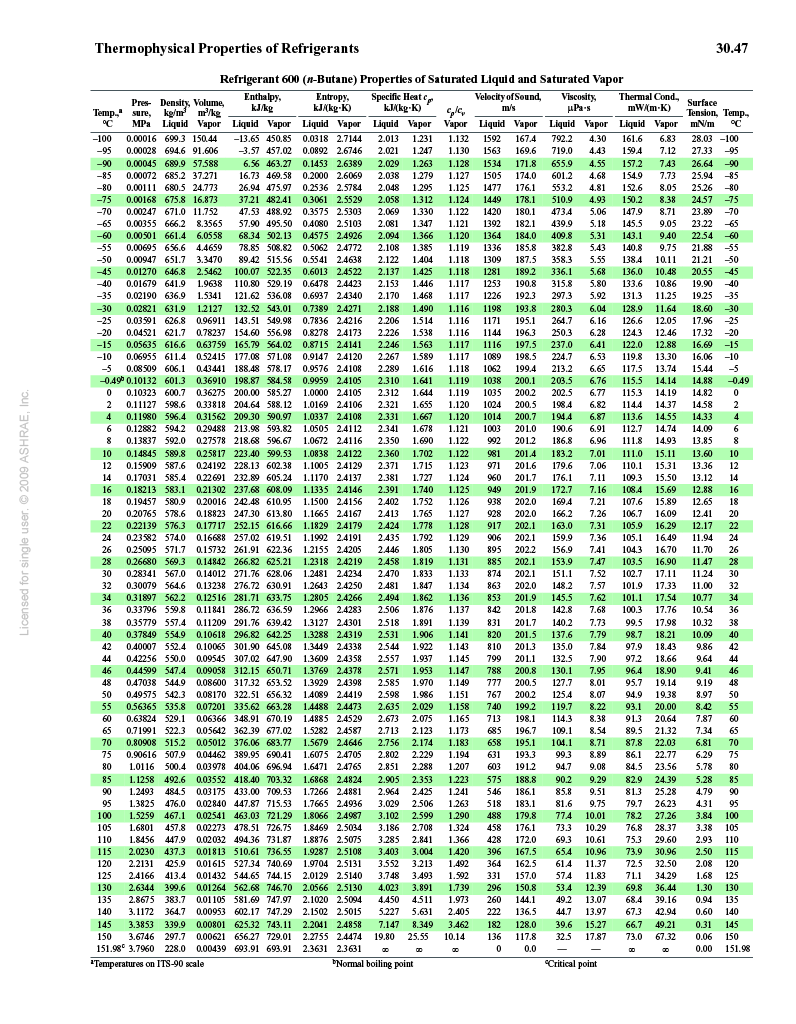

So simply increasing the pressure of the system will cause the gas to condense at a higher temp. In doing so, you will need less heat content (enthalpy) to both boil and condense the same mass of butane than at a lower pressure. ![]()

Think about a refrigerator… it doesn’t have a chiller attached to it to function, instead it uses the air temp and a heat exchanger to condense at a temperature much higher than room temp, say 150f condensation temp so that even on a 100f degree day it will still condense the vapor. For example, I have an isobutane deep freezer down in my barn that uses the air to condense the gas that runs the freezer.

We have an MTA TAEevo TECH 121 keeping the Huber Unistat 915w happy.

Max ambient temp for the CS 100 is 32c, and it struggles when it gets close to that.

We do maintain pressure during recovery as well. Recovering at 30c.

It starts to struggle, if it gets too hot it’ll shut right down unfortunately. it’s the downside to Hubers being super sensitive

I have mine in a 20 foot sea can with a dedicated 5 ton AC chilling it, when we Start it up for the big temperature swing we vent all the air out but once Temperature comes down Initially, we close it up and it maintains even when outside temperatures are in the mid to high 30s

Im currently using a -40/40L chiller using pumps tho, but before enters recovery tank i use a jacketed coil passing water thru at 50f then enters tank that has internal coil i run the -40 thru,

Works great and maintains temp setting without gaining heat or using dry ice or ice

16kw is 16kw. You’ll have to give it 16kw of continuous heat for it to recover at it’s max potential. The temperature of your solution will be dependent on its mass.

Unless you’re a real masochist or trying to fool dumb investor money, I can’t imagine a good reason to run Hubers in a production cannabis environment

Because all chillers need to be Huber, and all valves need to be Swagelok.

It’s actually about availability and warranty.

I got a used Huber at a discount which I now use for my injection which I totally love so when I was looking to making the switch away from dry ice, I took reliability and warranty as well as the ability to immediately purchase a unit and have it shipped Huber came out on top, and I have no regrets. Talk shit all you want.

My CS 200 is performing like a beast far past the warranty and when I had my refrigeration tech look it over to do and do Maintenance he was amazed on how clean the wiring is and how nice everything set up so I don’t have complaints

I’ve had four or five Huber’s through my facility and the only thing that has amazed me about them is how much people pay for them when they’re brand new.

The wiring is acceptable. The component selection is proprietary and thus questionable. The controls are marginally acceptable, if you got scammed into paying for the top tier.

They have been the opposite of reliable in my experience, and we don’t even lean on them all that hard.

I ran 3x Unistat 815’s and detailed how awful they were in a thread here a few years ago, I’m talking shit from experience.

We had several failures requiring a tech to come out for repairs while still under warranty, which is at odds with maintaining consistent production. Dollar per kW of cooling power, I’ve been less than impressed. @ me after a few years out of warranty.

What are the current recommendations for chillers is Huber is out?