Looking at that with a microscope and at different kind of material, I found the sweet range is somewhere between 63 and 160 microns. It depends on strains and growth conditions.

Complete with pieces of sandstone and a scorpion one time. Heady terps, bro!

Did you get that scorpion buzz tho?

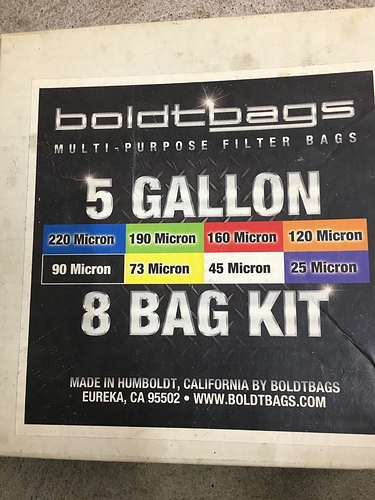

These were the ones I had.

Brand new box. 10 years old. Bought a backup and never needed it

![]() Just remember dry ice chips away at cheaply made bubble bags. Be sure to inspect your bubble bags before using them and to replace regularly.

Just remember dry ice chips away at cheaply made bubble bags. Be sure to inspect your bubble bags before using them and to replace regularly.

I’d call it 120-63. I’ve never found a good pay layer above 120 personally. I’ve never looked at 160 under a microscope either. There’s usually enough green in that I just toss it.

I’ve actually never used dry ice in mine. Only water and ice.

If it ain’t got streaks it ain’t chiiiiiitttttt

125-63 is sure the major fraction in many case.

But I often observed that the 125-140 fraction have a higher potency…

I’ve seen interesting thing up to 160, depending on how the sift is done, you don’t get much plant debris.

I’ll take a better look at that!![]()

I was saving this to post later, but it may help someone now. These are my notes over the last couple weeks. This isn’t final, and I bet I could explain a few steps better to others. Here goes:

Using 4 5-gallon “bubbledude” bags: 73, 90, 190, 220

Using fully dried, cured, not even frozen trim that is a year+ old. It’d be best if it were just chopped down after a great proper 2 week flush, and immediate freezing after harvest

***As with all extractions, Quality material in, Quality material out and

colder extractions work better. You will see yield and quality loss directly in proportion to rising temps in washer and while using the bags. Use an A/C, use minimal water during rinses, and work quickly with (few) breaks or downtimes.

-

Limit runs to 80g for best returns, 115g max just doesn’t cut it. too big.

-

Put Ice in washer to 80%, fill with water to ~90% (*high enough to float the bag, not high enough to be splashing out during runs)

-

Let ice and water sit for 10 minutes before placing work bag to thoroughly cool water. (during this time I weigh and prep the work bag with material)

-

The work bag gets no ice inside, just the 80g of material broken up, even the nugs need to be broken down.

-

Submerge bag to float evenly in all directions. Give cushion for up and down movement of about 2 inches. The less material, the less issue you’ll have

-

Soak work bag for 10 minutes

-

Run 20 minutes (15 minutes + 5 since timer is limited) [*at the 10 minute remaining mark, pull the bag out and knead it to unstick the material and loosen things up. This increases returns for me.]

-

Dump out washer through your bags in proper order in the bucket

rinse out the machine 3 times using sprayer to clean remaining trichomes out until no foam is present -

Run through bags, use ice cold water sprayer to get the most out of each bag

*Tip: use 5 gal bucket to easily scoop material. I don’t put the bucket upside down and push it out like Bubbleman does, but I just have a separate empty bucket and place the bag in it like a trash bag and pull the sides down to get the screen tight and easily scrap out material, spray with ice water, ad get the remaining material out. You can do it faster doing other ways, but this allows you to clean your bags as part of the process, getting you ready for the next batch with no delays -

Rerun extraction water a second time along with the work bag(after spraying off bags of any remaining material) through the machine by dumping it in a bit at a time into the next run. You want to reuse your water as much as possible since it is ice cold. New water added usually requires you to pre-chill it with ice before adding otherwise you will loose efficiency and yield.

-

Place used workbag into machine with used water, run another 15 minutes to get the most out of material. 3rd runs aren’t worth it in this case.

It takes me 6 hours to run 4 batches twice (1.5 hours per batch)

In 12 hours I can generate ~40g minimum, (up to 50-100% more if it were fresh)

Drying:

- Keep your 73 and 90 separate from the 190 (if you dab) when placing onto drying sheets

- On a sheet pan with 1 layer of parchment paper, scoop each ‘bubblepatty’ out of each bag you are working and thinly place onto pan. Do not squish down, it will destroy air pockets and cause mold later. You can spread it out by stretching it, but keep it thin and connected to itself for easy removal once dried.

- Place pan under a ceiling fan (on lowest setting) in a cold dry room for 18-48 hours. - This is a cold dry (not really a cure) and won’t work for everyone in humid conditions.

- Lift patties when they are dry by peeling off of parchment paper and placing into a quart jar like pringles.

This is not a final process. This hash can be further refined into rosin (press), into temple balls (hand pressed), or ground down into sand, pressed, folded, and heated into driveway hash.

Doing this with 5 gallon bags is a waste of time but a right of passage. Hone your craft for 10-20 batches and then do it right with a 20 gallon set of bags and washer.

I have no microscope pictures of differences between screen brands, but the general consensus among ourselves in Oregon is that all bubblebags come from the same 4 factories and the screens are the same. Bubbleman, bubbledude, Humbolt or something, and another that nobody has seen or remembered. I bet there are many brands that never took off. I operate with the thinking that none of these bags are especially premium or have holes that are 71 or 75 micron instead of 73, etc. I think the screens are all about the same size and that build quality of the sidewalls are the weakness in the cheaper bags.

Best of luck, stay cool!

The “washer” is a dedicated washing machine?

I keep thinking about somehow affixing screens to the bottoms of trash cans that stack inside each other, and using those instead of bubble bags. I need to scale up from the 5 gallon bags, but don’t want to buy a washing machine.

Workhorse of the 5 gal bubblebag home industry costs about $60 shipped and last a couple years usually.

I forgot how much work bubble hash was…back in 2003 I put in a lot of hours running drills with paint mixing bits up in the hills lol.

I may have to do this though…I have a new 8 bag set and a new washing machine.

i just used to dry sift using a screen. no waiting to dry not as much hassle and the taste is better than water hash i found. probably not as pure but the taste factor alone makes dry sift better for me

Boat hoists and a bank of washer machines, so many raised beds and compost piles built in those day

“Dry sift is for head stash, bubblehash is the rests’ to ash.” - Plato probably