This route with zinc chloride/bromide is for making d9 but I’m sure we’d all love a safe and simple way for d8 if your willing to share.

You are in the wrong forum for asking questions like this. No one is going to dumb it down for you for free here.

He is clearly not American, you forget most of the world has very draconian cannabis laws and people have horrible access to low quality cannabis. Converting CBD is attractive if you look at it from that perspective.

@IsolationChamberLab I see the whole picture now.

@CrazyGoat apologies for jumping on your case without fully understanding the situation.

BTW I am only 1st generation American… mis padres son de Europa.

I wasn’t paying attention and posted without reading everything first. Just seemed like a hazardous environment could develop using such ingredients.

@tweedledew ya D8 is easy

By other side, I won’t get horrified by the number of lenguages you speak, American.

(dont try now to lie and say you speak more than one)

Please post pics of your set up when it’s assembled.

Why would someone be using ZNCL2 ( which is used for d9 ) to make d8?

Everyone knows Tosic is the way to go for d8

They just don’t know what solvent to use or the reflux time

The sop I use to get almost full conversion is from @Photon_noir, and the clean up is simple.

Water washes will remove any tosic acid left after the reaction and if you run your reaction in a hydrocarbon then you can water wash immediately after

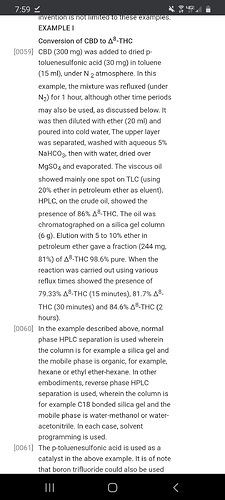

Here kids have fun

This is directly from that patent

you could monitor by TLC pretty easily if you make up a CBD standard for yourself. I like the KOH test dont get me wrong, but once you get to lower amounts of CBD starting material (when the rxn is mostly done but not all the way) you might have a difficult time making a definitive observation with the beam test.

You could degass the solution (if youre in solvent) by pulling vacuum until you see some bubbling solvent, then back fill with Argon three times. Thats about as much as I would perform for a hydrogenation so its about as good as you can do here. Once youre satisfied with your degassing, then begin heating the solution and let the reaction run. Argon isnt that much pricier than Nitrogen, sure you might want to go with dry argon for proof on concept work - if the reaction works try again with cheaper/wetter argon if you wanna see its toleration for water in that way, if that works then try with even cheaper yet nitrogen. But eliminating water at proof of concept removes a confounding factor, but it wont make much of a difference if you dont make attempts to dry your glassware/system before you even charge any reagents. If you suspect water is some sort of culprit, your attempts to eliminate its potentially confounding affects you must thoroughly ensure its not present if that makes sense. For truly dry work I’ve heated my glassware pretty hot and let it cool under a significant stream of dry inert gas (dry nitrogen would be smarter than dry argon since youre just pissing it away in this step without any reagents present).

So the d9 reaction steps are similar to the d8 just switch the just change out the acid?

I mean even cbn is a reflux is a certain solvent / catalyst

D9 you need an oxygen free environment

D8 you don’t

D8 is a simple chemistry procedure involving. 1 catalyst

Either tosic. Acid

Citric acid

activated carbon

Or one of the acitic bentonite clays

T5,T41,

It’s pretty straight forward with little preping

To make D9

There is a minimum of 2 compounds needed and a 3 is often used

Mol sieves to control the reaction and a high boiling point solvent

Miticulas prepping is advised

To do this reaction in as dry conditions as possible

It’s great my friend, thank you, but you need a ton of dichloromethane, by the other side this is the best sop in terms of high yield I have seen for D9 thc.

But don’t you think that that quantity of dichloromethane makes it a little unpractical? Is it necessary that much?

About this process:

CBD can be converted into delta-9-THC with anhydrous ZnCl2 at 150° without solvent (perform reaction best in vacuum as product is sensitive to oxidation):

Heat 0.5g CBD with 0.09g anhydrous ZnCl2 under vacuum with stirring.

After 2 hours 40 to 50% delta-9-THC have formed.

. Why this only yields from 40 to 50%?

How to optimize this reaction to get a higher yield?

Is it time? Quantities?

You tell…

Thank you.

Yes. Below about 1% CBD, it becomes almost impossible to distinguish with the naked eye. A spectrophotometer would do it, though.

I am SO glad you brought up oxygen condensation via LN2 in a cold trap, @RushChem ! Thank you! I am worried that someone will eventually have a serious fire or explosion due to all the LN2 cold traps being sold by Chinese vendors over the past years!

Yes! Water determines D8 or D9 in all of these reactions… it is the difference between a Lewis acid and a Bronstead acid in many cases!

…that’s your answer, btw, @Roguelab ![]()

Im just curious about something dear friends.

In a schlenk line, or in any reaction under innert atmosphere, why do you need a constant supply of nitrogen?

I can see the oil bubbler constantly bubbling, that means; the nitrogen flow is constant.

Why not just making sure that all the system has only nitrogen, then turn the tank off, and then, with only that innert atmosphere in all the system, make under it whatever reaction you need for the time it can take?

Does it get “wasted” or something?

I wish my question were clear enough and not broken English ![]()

It is clear enough, @CrazyGoat ! The reason you don’t close your system is pressure! To maintain a consistent safe pressure, the gas (and liquid) must be able to expand if you are heating the system… otherwise, without that continuous pressure relief, it might pop apart or even shatter!

When it stops emitting vapor/gas (by heating or reaction), you also need to allow the liquid to contract when it cools without sucking air into the system… so the continuous flow of inert gas also fills the growing headspace as liquid cools.

In this way, the interior of the reaction system is never exposed to air/oxygen/humidity while conditions can still allow reactions (such as when it is still warm)!

Thank you for your clear answer.

But photon_noir, isnt the pressure relieved by the oil bubbler? I am asking about closing the gas tank (in schlenk or simplier systems)

I don’t see why It can not be bubbling the excess pressure produced by the reaction if the gas is closed. (it’s connected to a gas bubbler at the end right?)

I read in someplace that something that can happen with the oil bubbler is that the oil can be suck into the system…

Now I understand why after reading your second part on why you need to have a constant flow.