ill check that grease out im hoping i can get by with this run using the dow grease, the spec sheet says its good to 200 C i thought our temps shouldnt get that high

go for it. my experience is it works, but you will get lower percentages

You’re distilling at 170-215c roughly, depending on vac level, you’re definitely pushing it. @lefties.cannabis is trying to save your ass. I’d listen to the advice given.

use ptfe, stainless will expand and break the joint, too much expansion.

Thanks all I really appreciate the feedback, ive ordered some krytox. In regards to the thermowell, i had a feeling steel and glass wouldn’t be ideal for that very reason. @Soxhlet are you suggesting i use a ptfe 14/20 adapter and a steel thermowell or an entirely PTFE thermowell, seems kind of overkill. it seems many of these are threaded which seem useless for this glass application, can you suggest any particular setup?

I wouldn’t make it entirely from ptfe, just the joint. Really the mantle is best controlled with the thermocouple directly in contact with the mantle. That way the pid controller that is controlling the heat has instant feedback. You ever put your feet up near a campfire with boots on? the soles of the shoes get so hot they can smoke before your feet start to feel the heat. Your mantle is in a similar situation. Eliminate the internal probe and your source of leak for a more accurate way to control heat imput.

Check this out: Looking for 4-pin plug to enable internal thermocouple in Chinese heating mantle

maybe im confused but i thought the thermowell was to be used in place of the thermometer adapter which measured head temps. my best source of leak appears to be the head thermometer adapter. my mantle uses an old school regulator so theres no thermocouple input. it simply regulates on/off i was thinking of monitoring the mantle temps with my kangaroo.

No this is correct, thermowells are often more leak tight than the o-ring style thermometer adapters.If you just need conventional thermometers these work well for reading head temps.

Otherwise you will want a good thermowell.

You tried glidman rings for sealing yet?

https://www.fishersci.com/shop/products/14-20-ptfe-sleeve-3-pk/509557920

I have that type of ground joint thermometer on my other head and it seems to work well though it is a different taper from the head im using now. Thanks for reminding me they exist; The gildman rings seem perfect to seat a thermowell in, could you seat all the joints in them for hassle free sealing? Can you turn a joint under vacuum with these? I have some PTFE sleeves 24/40 but i found them to be very leaky compared to just grease they are very thin maybe a mm are these gildman rings thicker?

do most people use thermowells for the BF temp or both in the head and BF

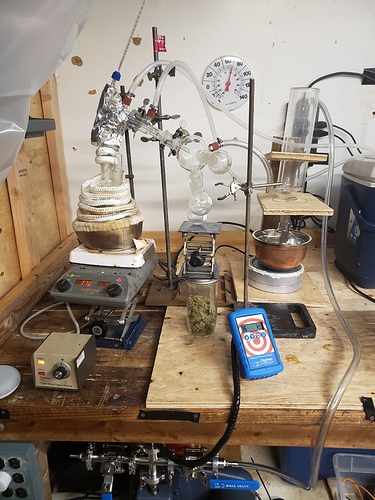

got it loaded and finally sealed up, just need to pick up some dry ice. thermometer adapter was sealed with a more generous application of grease. Upgrades on the way but im antsy to see an end product.

Thanks for all your suggestions

Is your top joint 14/20?

yeah you can use them for all the joints. You can also use distillate to seal them instead of grease.

@spdking come out lets fight! ![]()

I would recommend a thermoewell over an adapter specifically because of the o ring seal issue

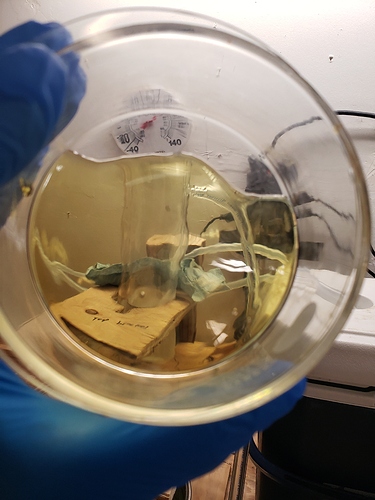

So I left the pump running on low heat while I got the dry ice, and my first fraction started coming at 120 in the head 165 on the mantle amd it started coming fast and clogged my head. I didnt see what I would consider heads based on my experience with first pass . This first fraction looks pretty good, perhaps the residual stink was pulled out when I left the vac on?

First pass vacuum depths are higher during the heads/mains transition and makes them hard to separate. Around 165ish you’ll see it start. Depending on the material your vacuum might not be suitable to separate them until the run is over

It’s actually second pass the first pass split fairly well into 3 fractions. However the main body still kind of stank.

my second pass didnt split into fractions like I expected and it came over between 120-140 C at the head it stinks minimally and a drop of terpenes hides it well in my small scale test.You never want to walk away during heads fraction distillation

That shit needs a cold trap to stay cold af while you’re pulling volatiles or heads. Otherwise you’ll never pull deep vac on your body

I didnt walk away except to grab hot water to get my clog unclogged

And my cold trap was filled to the brim with dry ice and isopropyl. Nothing was collected.

Word.

I really good practice sop for splitting fractions is controlling pump dry vacuum quality.

One trick is is to get right above temp of thc, then back off - nearly all temp off… Allow system to cool under vacuum while pump runs. Bring below 90c. Then swap all forward flasks and maintain dry surfaces. During this time allow pump to keep running to burn off. Then you can assemble everything and allow pump to continue the system being pumped down … Then after the pump is ready - usually at the point where the boiling flask hit near room temp you can turn temps up and bounce the thc fraction out a bit lower actually than you normally would

That makes a lot of sense essentially a more complete purge of volatiles with BPs below thc.

I kind of did that in a sense because of an immediate clog, I cooled down the system ,all the way off untill could clear the clog and them proceeded in a clean cow bulb.