maybe im confused but i thought the thermowell was to be used in place of the thermometer adapter which measured head temps. my best source of leak appears to be the head thermometer adapter. my mantle uses an old school regulator so theres no thermocouple input. it simply regulates on/off i was thinking of monitoring the mantle temps with my kangaroo.

No this is correct, thermowells are often more leak tight than the o-ring style thermometer adapters.If you just need conventional thermometers these work well for reading head temps.

Otherwise you will want a good thermowell.

You tried glidman rings for sealing yet?

https://www.fishersci.com/shop/products/14-20-ptfe-sleeve-3-pk/509557920

I have that type of ground joint thermometer on my other head and it seems to work well though it is a different taper from the head im using now. Thanks for reminding me they exist; The gildman rings seem perfect to seat a thermowell in, could you seat all the joints in them for hassle free sealing? Can you turn a joint under vacuum with these? I have some PTFE sleeves 24/40 but i found them to be very leaky compared to just grease they are very thin maybe a mm are these gildman rings thicker?

do most people use thermowells for the BF temp or both in the head and BF

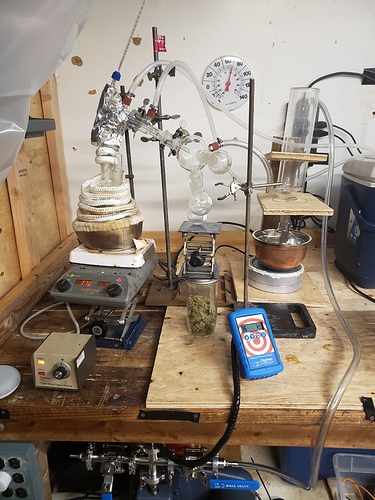

got it loaded and finally sealed up, just need to pick up some dry ice. thermometer adapter was sealed with a more generous application of grease. Upgrades on the way but im antsy to see an end product.

Thanks for all your suggestions

Is your top joint 14/20?

yeah you can use them for all the joints. You can also use distillate to seal them instead of grease.

@spdking come out lets fight! ![]()

I would recommend a thermoewell over an adapter specifically because of the o ring seal issue

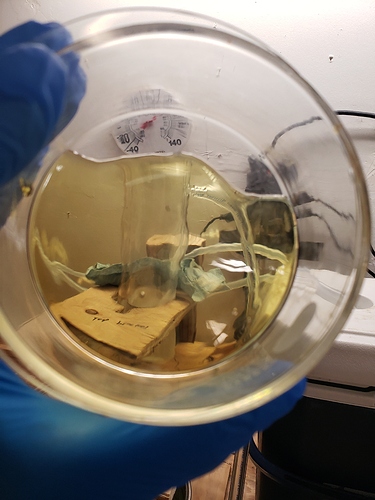

So I left the pump running on low heat while I got the dry ice, and my first fraction started coming at 120 in the head 165 on the mantle amd it started coming fast and clogged my head. I didnt see what I would consider heads based on my experience with first pass . This first fraction looks pretty good, perhaps the residual stink was pulled out when I left the vac on?

First pass vacuum depths are higher during the heads/mains transition and makes them hard to separate. Around 165ish you’ll see it start. Depending on the material your vacuum might not be suitable to separate them until the run is over

It’s actually second pass the first pass split fairly well into 3 fractions. However the main body still kind of stank.

my second pass didnt split into fractions like I expected and it came over between 120-140 C at the head it stinks minimally and a drop of terpenes hides it well in my small scale test.You never want to walk away during heads fraction distillation

That shit needs a cold trap to stay cold af while you’re pulling volatiles or heads. Otherwise you’ll never pull deep vac on your body

I didnt walk away except to grab hot water to get my clog unclogged

And my cold trap was filled to the brim with dry ice and isopropyl. Nothing was collected.

Word.

I really good practice sop for splitting fractions is controlling pump dry vacuum quality.

One trick is is to get right above temp of thc, then back off - nearly all temp off… Allow system to cool under vacuum while pump runs. Bring below 90c. Then swap all forward flasks and maintain dry surfaces. During this time allow pump to keep running to burn off. Then you can assemble everything and allow pump to continue the system being pumped down … Then after the pump is ready - usually at the point where the boiling flask hit near room temp you can turn temps up and bounce the thc fraction out a bit lower actually than you normally would

That makes a lot of sense essentially a more complete purge of volatiles with BPs below thc.

I kind of did that in a sense because of an immediate clog, I cooled down the system ,all the way off untill could clear the clog and them proceeded in a clean cow bulb.

Can anyone comment on the residual stink after 2nd pass? Do I need more crude pre-prossesing. My crude is a cold ethanol extract though ac and celite

Its just very difficult to separate those fractions to a larger enough degree that you won’t smell them. A lot of people loose sight of this fact but if you were to think about the separation as a function of time it is asymptotic. You can never fully remove anything to a complete degree. Absolute values are rare in nature.

With your setup you’ll need to really take the time to split them which as they become smaller n volume they become harder to separate. A fast and easy method is to use the hot condenser tech.

If you really want to experiment some hot inert gas could aid your separation.

I was looking at my glassware just thinking a 3 way adapter and this right angle adapter look a while lot like hot condenser tek but it’s totally understandable that it’s very to remove the smell completely, I just wanted to make sure that’s normal lol. It’s pretty faint compared to what it was

I’ve got the capacity to make some hot argon do you mean to experiment with adding hot gas as a means to help pull the smelling molecules out with the gas I could see that helping

Yep exactly. It takes a larger pump to pull out the inert gas along with the cannabinoids but you should find that the momentum transfer is different and you don’t need as high of temps at that vacuum range. Think about it, a regular vaporizer will work at atmospheric pressure but only around 200°C whereas under vacuum it turns to vapor at that same temp range but under deep vacuum. Point being that under greater vacuum the momentum transfer is reduced but the resistance to flow is also decreased which balances out. The opposite is true with inert gas sparging.

For vacuum ovens nowadays everyone knows you need vacuum and inert gas to complete your purge in a reasonable amount of time. This trade off is obvious now but most people haven’t put this method to use with short path.

I’m a complete novice in this field so I didnt think about its application in the oven as well but that’s a great tip thanks!

Depends on the stink. Is the material runny? If it’s perfectly processed aside from the heads split, you probably just didn’t separate your heads fully.

Sit the material at 160C and 50 micron. With your setup it shouldn’t be gushing mains but barely pulling liquid. Watch if it cools into sludge in your receiving flask or if it stays runny. Either way, if it smells and appears to be not mains, that’s your taste/smell source and your “heads”.

If it’s more of a burnt smell or taste you may be distilling tar into your mains fraction. Tar is what’s left behind in the boiling flask at the end of first pass distillation. It will cause the material to smell burnt and may be from popping in the flask during mains distillation, which causes liquid particles of tar to be pushed into the head and collected. You can get rid of this smell with another pass, usually it goes away after second pass though so I’d put my money on the heads being the issue