So installing some c1d1 fans in extraction booth and want to size them appropriately. Does anyone know the air evacuation/exchange mixture for hazardous locations. Booth is 9ft x 16ft. We had purchased 1600cfm exhaust and 900cfm incoming fresh air.

PSI just wanted 100 cu ft/min over my workspace

Usually u want a mix of incoming air opposite side wall mounted high coming in at slightly lower speed than exhaust which is mounted low. Basically I built them a wind tunnel. Looking through nfpa documents but can’t find a standard. 100cfm per minute sounds low. Trying to be in line with Nfpa standards.

I’m pretty sure they meant 100 ft/min - how fast the air travels across the space. Speed, not volume.

I’ve heard that magic number tossed around a LOT. I don’t know if it’s supported in code anywhere. I’ve never seen it set down anywhere official. I also haven’t looked all that hard.

From a logical stand point, it’s about boothfuls of air exchange per unit time (which should also mean you can use velocity, but I think it’s easier to spec the fans using volume based metrics).

you’ve got CFM on your fans. Give us cubic foot on your booth…or calculate how often those fans can turn your booth over (/min). No clue what the target is. Do know it’s preferable to have your sniffer kick shit into high gear when it notices you’re leaking (and have the booth be proactive about things on fire)

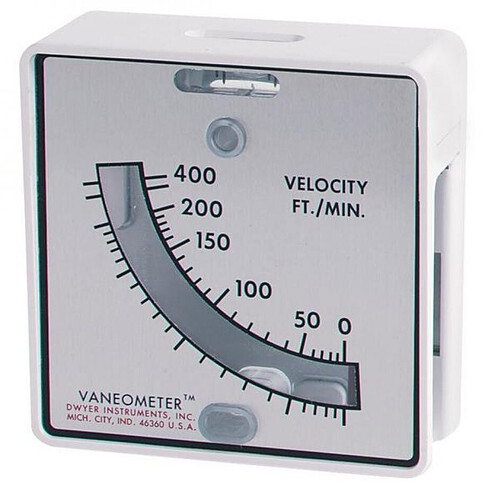

That used to be a denver regulation (maybe still is) that they were hella strict on. First company i worked for built their own c1d1 booth they had their stupid meter check every inch to make sure everywhere got a minimum of 100 ft/min and made us buy a cheap one to have on hand so we could verify proper airflow. we had to go on camera once a day to with and take note of it

Probably not a terrible place to link this…

Although I should probably make sure there’s not a topic for it already…

Edit: currently no other hits to NFPA 420 but if that changes the link becomes useful ![]()

there are a couple of hits to the 2018 NFPA section 38

including: NFPA1 Chapter 38

Appropriately it will be released as NFPA 420… Cannabis Fire Safety Resources | NFPA

I believe that one of the API standards says something along the lines of “do 12 ACH and you’re cool, or do a fuckload math and get it down to as low as 6.”

That assumes the system is designed by someone who knows what they’re doing of course. It’s not as simple as “have sufficient air, am compliant.”

@anon16547145 what do your engineers say about this?

I love we are talking about this! Okay so here’s the deal:

100 linear feet per minute *** you can buy a “Hot Wire Anemometer” to test this. When you have complete linear air velocity, you shouldn’t have gaps where gas can puddle. This is why we have slotted panels over a set of diffusers that enable this linear air flow. You should check the hot wire anemometer over each of your slots :). This is what the engineers do on a “field verification” of the product.

Of course you should have explosion proof fans, and the interlocks that go along with those and the sensors to clear the room before it ever reaches the lower explosive limit of the solvent you are using.

LINK For the Hot Wire Anemometer BELOW:

Ps - your ducting size and static pressure drops, diffusers, and other variables may affect the actual amount of air going through your booth. It’s important to calculate this with a Mechancial engineer prior to choosing your fan size / motor size.

How tall is your booth?? Per the Industrial Ventilation, a manual of recommended practices, the correct flow is 100 surface feet per square foot of face area, not 100 cfm per booth square feet, though some rules incorrectly call for 100 cfm per square feet. Face area is booth width x height.

Envision a column of air the width and height of your booth moving at 100 feet per minute toward the exhaust slots and conveying vapors with them.

I love the collective intelligence we have here. I ordered the anemometer and will test that out next week. I will post my results. the total cubic sq footage is 1152. Yes the fan is connected to explosion proof outlets with metal conduit. There is a Rki ps2 we are using to sniff the air to trigger fans but do I need to install control unit in exd box or can I just use an extended probe and locate outside?

Thanks everyone

The sensor should be located in the exhaust slot end of the booth.

Our booths have the sensor 12” off the ground 12” in front of the exhaust slotted wall.

A control box is needed to be compliant to NFPA. This would (1) turn on the fans when the lights are turned on and (2) purge the fans when the sensor is at 10/25 percent of the lower explosive limit (LEL). You can also throw a VFD (controls the fans) and even convert the 3 phase fan power to single phase with no issues on bigger industrial fans like the ones we use.

Hope this helps.

You are the people for a booth. have you done lots of tesing like just having an open flame and a leak and the booth doesnt light up?

Don’t bring a flame into a C1D1 room. The entire purpose of this room is that it doesn’t create a spark. You need a spark in addition to a gas level over the lower explosive limit and below the upper explosive limit. These are determined concentration amounts of those volatiles in the air that gas sensors normally alert fans to clear at 10/25 percent of the lower explosive limits. This eliminates the gas ever getting to this concentration in the air, AND removes the ignition (flame). All in all, it’s a simple and programmable number that doesn’t need to be tested with a flame and a can of butane

What is recommended for explosion proof fans? I’ve seen quite a few marketed as such by distributors but then the manufacturer will be saying not suitable for flammable/explosive fumes in the user manual

and on that topic- what is involved in those fans? Is it just a brushless with potted connectors? Im a diy guy and not a c1 d1 guy but what makes the fans or pumps rated for c1 d1? I got a trs21 and its extra for a rating?