Thats a little smaller than my pilot plant was. I bought all the toys to scale up further before the market fell apart and never got to use the big stuff. It was hard finding a matching pair of 1000l reactors with the right specs but damn those were fun days…retirement is kinda boring

Hahaha I don’t doubt that at all duder, pumps have helped me more than I can express

My system will have double collection vessels with the 300l tanks, so I should be able to inject a 7-10lb column every 30-45 min. At minimum

I think something of value is worth having here. It’s like a reboiler on a petroleum distillation column.

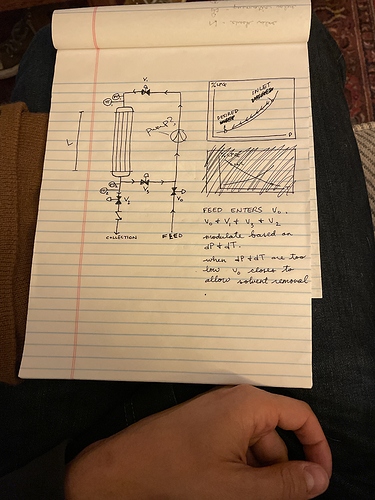

Solvent heavy feed is limited on what’s coming out of the FFE, by modulating the V0 valve. If what comes out of the FFE is too high in pressure it’s pumped back through V3. Once it reaches the appropriate values of pressure and temp it goes through v2 into the collection and V0 opens up again.

It’s really not a solid design, but just what I could think up in a quick second. Wouldn’t be easy to make a balanced control system, but it definitely seems possible.

It’s figuring out the pump that’s a bitch

Some advice…move away from columns. We ran dual mat vats. 250l each and put material in nylon brew bags. While one was running the other was being loaded. Alternating big vessels was way faster than any rack and column system.

I get that but I have a real hard time thinking the extraction efficiency is worth a damn going that route. How do you rinse the oil rich butane from the bio? How do you recover solvent from the material column safely and completely

Run 2x solvent vol to mat vat volume. We rarely got another % yield rinsing again. Put a sprayball in the top of the reactor. Solvent from the material is recovered with…you guessed it…a compressor!

Lol…

I am in the process of switching to a passive hybrid system . I have a mvp150 it works great after figuring out how to effectively use the pump . The biggest thing for me is not having to use any nitrogen at all! Using hot vapor loop / warm vapor push you can eliminate nitrogen and then some . I use it for defrosting / thawing columns too which is great it can do a 6×48 in as little as 1 minute . I think a hybrid is the best it has the benefits of both active and passive while allowing you to be able to get the best of both worlds ! Another benefit of active is the ability to recover with a high psi on your recovery tank if your system was passive you could not recover in a solvent tank at 50+psi . An active system could run itself on the warm water in the coils circulated to the evaporation vessel moving the cold water back to the coils on a loop obviously it would not be super fast but better than no recovery at all . Passive systems have restrictions on how you can operate the machine since they work on the sole principle of thermodynamics . You can say its cause active guys don’t understand thermodynamics when its just different ways systems can be ran with active having less restrictions . Sure pumps can suck but they can also suck real nice if used properly lol . I am not trying to argue what is faster passive wins but there is certain things that you just can not do without a pump for example nitrogen is a must on all passive systems

Hmmm… my next qualm would be the ability to only run salads with your method. I like the ability to run small 7-10 lb runs of different strains

You know your not getting anything like even coverage on the bio in that situation. We’ve been over this. Someone in China made a reactor and called it a material column on accident lol

using a pump for bulk recovery is still silly.

recovery of that last bit of vapor… sure.

First 250 was flood and soak second 250 was rinse. We measured yields and were happy with the thruput/efficiency compromise. Nice thing about the brew bags is if the bottom one was a little sticky you just load it in the next batch.

As far as small batch, ya, volume has its drawbacks. But running columns was so much work with so many leak points after I built a 50# rack I was happy to sell it and never fucking touch one again!

run a very small collection under your evaporator and eject it into something else using pressure.

I think bulk recovery of solvent passive is the way to go . I did a consult for friend to go passive hybrid got him screaming 3lbs a minute now . Trust me i am a firm believe of bulk passive recovery !

The pump/passive argument is circular. The biggest passive system you can imagine can be sped up by an even bigger pump until the limit of heat input is reached. Back and fourth forever. The biggest gains in time after meeting the scale you target is process efficiency. Honestly after all logistics becomes more a challenge than the process itself. That and people fucking up…

Any idea roughly how much dry ice usage and heat energy that takes?

Ive run a hybrid setup of a couple years, its great!

122lbs of dry ice an hr