Ok , I’ll make the gap .08" should be enough clearence for a tight fit. You may need to mess with the scale size 1 or 2 precent if it isn’t fitting.

Much appreciated let me know if you need a few shekels for your time.

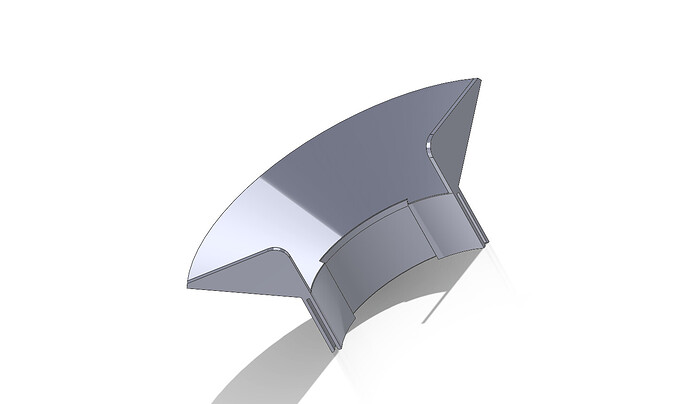

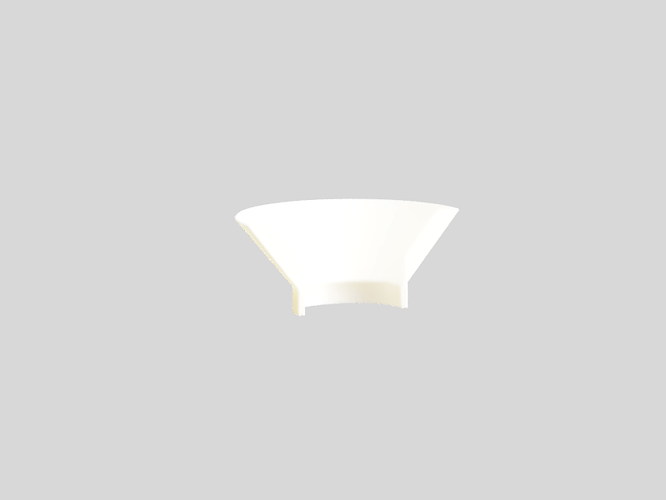

Here is the model, its on my grab cad. Let me know if it needs any adjustments, or if you want it designed a certain way. No need for any compensation here, quick stuff like this only takes me 3-4 min to do. Honestly I just like helping people and the DIY spirit.

Edit:

By the way I think the best way to print this is on its side or with the funnel facing down.

The object is 120* if you decide to lay it on its side for printing, this will help you orient the part .If the funnel fits too tightly you may try scaling the print larger by a few percent.

HAPPY PRINTING!

That is fucking awesome! Your the man!!! @Soxhlet

I have a similar design for the 5" Sleeve. It helps to print it at an angle to minimize the use of supports.

Nice work @Meezey ![]()

![]()

That’s dope. How’s it holding up? What’s the total cost to make that?

loc-line is fairly rigid, it supports itself

Maybe 50-60 bucks? Assuming you do it perfect first shot

I meant how has it held up to usage.

How long do you get out of a 9v battery?

This is interesting I’d wanna make some with my glass blowing name on them and sell them with rigs I make haha

It never really worked how I wanted it to, I need to get the sensor with the 5 degree FOV lens or work out the fresnel lens I need

Aside from that it’s fine, it’s on my desk a couple feet away. Need to circle back at some point

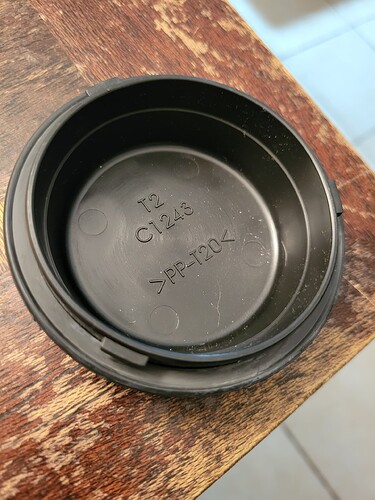

Just installed leds in my subaru instead of changing the head light that blew. Of course the module doesn’t fit into the head light case which is gasket sealed. The compartment is too shallow to make a new case that just goes straight back to house the new components, they just dangle out the back right now.

I don’t want water in my headlights and I live in moist Florida. Any idea if something can be printed to hold the electronics? Should I just cut the back off and glue a bag to the gasket and collar? Ideas?

Microporosity with the printed material will probably lead to moisture ingress over time, but as long as it’s shielded from direct water contact you should be okay for a little while.

Temps the part will be constantly exposed too will also effect the part over time, under the hood is a hot place, using a plastic like PLA the part will warp and probably end up cracking over time with enough temp cycles, PETG may be a little bit better in such environments. ABS is probably ideal in such an environment, just annoying to print.

Smoothing your plastic via vapor smoothing ie, acetone vapor for pla, dcm vapor for PET, etc etc can seal majority of the microporosity and create a “water tight” print.

All in all, yes absolutely you could accomplish your goal with 3D printing. Just don’t expect it to last as long as the original injection molded part:p

Epoxy coating is always an option as well

Do you need a cap designed? Iike @RockSteady mentioned prints can be porous, I like @pdxcanna suggestion of epoxy coating. I think spray paint would do the trick as well.

As for heat, I have printed stuff from pla that has lived in an engine bay. The headlight cap shouldn’t be too much of an issue, I printed an extension once that sat on top of a carburetor. Our welder at the time drove the car across the US for a car show with the part. I bet him a hamburger that it would melt, it ended up surviving the trip. Later it did start to warp, but it did impress me that little ol pla was capable of that.

If you want something made, make a drawing and post it.

Hey @Soxhlet I know this is kinda old but am hopping you may still have one of these available? I was just thinking of how to scale down and improve on the older larger version we all know and came across this.

You want a smaller model or just a cad model? If you want the cad model you can download it and scale it to whatever size you like. If you need something drawn in cad post a sketch with dimensions.

Or do you want a 3d print of the object?

For prototyping cardboard and tape go a long way.

I would like one already printed if possible?

Use a service like treatstock or crafrcloud and you can get it printed in whatever color/material

An ender 3 pro is also only $99 at microcenter for new customers right now if ya wanna go that route

I have an ender 3, the bed is smaller than the tronxy I was using at the time so the model would have to be scaled down anyway. I could print it for you for you, if you like. I’d charge something like $15 for the print plus you pay shipping ups. If you had specific geometry in mind I can provide modeling service at low cost, and print it.

For anyone else needing modeling service or printing:

I do not own a print farm or anything, I can handle the odd job now and then.

I like to print and model my own stuff, so primarily I would print your stuff in my down time when not printing for myself.I am not looking to make money with this service, just recoup my costs in filiment and wear/tear on the printer.I am offering this primarily to help the community.

In addition I would like to stick to pla plastics, they print easily and fit into my workflow.

Imo, this is the best option.