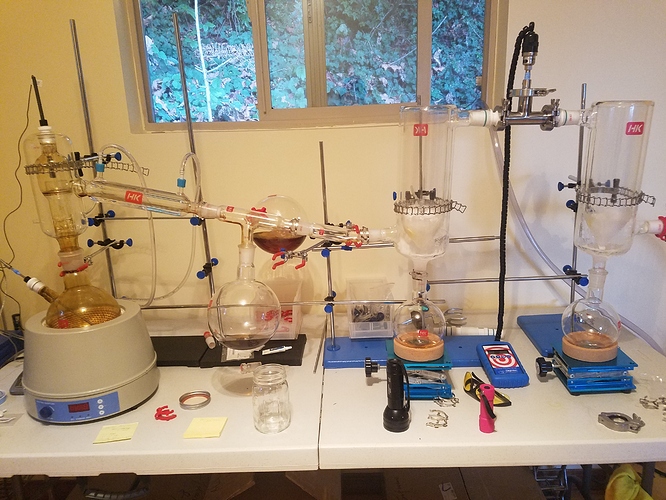

After months of preparation and reading many forum posts here, I attempted my first SPD run over the weekend. This is a 2L setup, glass is from David, thermo-couplers from BVV, Edwards E2M30 (ebay), polyscience recirculator (ebay), Dow Corning grease, Krytox LVP for around the head, PTFE sleeves, Bullseye, Kangaroo thermometer.

Not having ever done this, I didn’t really know what to expect and was very paranoid about it boiling over, so I went quite slow. The whole run took 8 hours, I’m guessing this can be speeded up quite a bit next time around.

I did decarb it before on a hot plate at around 235F for 25 minutes. There still seemed to be quite a bit of bubbling in the boiling flask, but maybe it was just typical boiling or a little bit extra. I used a thermo-coupler to decrease the pressure a few times to avoid boil over.

I went up slowly 5-10 C at a time. The 1st cold trap was dripping most of the run. With this set-up I also let the heads go into the 1st cold-trap. Recirculator was set to about 45C for the run.

The vacuum pump hits under 1 micron when attached directly to the Bullseye gauge. Attached to the SPD it came to 300 microns pretty quickly. It started losing some vac at around 102C, gradually going up to 800 microns at 157C. This had me really worried. At around 139C light green/yellow heads started to appear. Once the heads got stronger, the vac came back down to 300 within 30 minutes.

It seemed difficult to tell when to switch to main, but I made the switch at 170C. One thing that got me to change was I noticed increased head activity in general, so it seemed like a transition. I also noticed head temp increasing from previous 68 to 80 and then 100C. Nice stream of mains at 176C and 138 HT. Very gradually increased temp and let it collect over the next 2.5 hours.

By 190C, it started to look darker and thicker, I switched to tails. I noticed sub-fractions would come and go quickly, each time I raised the temp a little, another sub-fraction would come and then activity died down again. I kept doing this to 230C then decided to stop. In retrospect, I would not take it that high next time, as the last sub-fractions seemed especially thick and maybe not that worth collecting.

Things I’m still trying to figure out:

- I’m concerned the long run time may have degraded the material to some extent. How long should a run like this typically take? I’m guessing it could be done in maybe 3-4 hours? If vac is lower will it go faster?

- Is it normal for the vac to jump up and down like that?

- What do you typically do with the heads and the remains in the boiling flask? Are they useful or?

- I got a good deal on another Edwards pump, thought I might try to hook them both up to the SPD with a manifold to try for lower vac.

- I put grease on the joints but then didn’t run until 2 days later, I imagine it is better to grease them right before starting.

- Any tips on how to clean the head and other glass after a run?

- Could it be helpful to lower the recirculator temp from 45C?

Thanks again for this amazing resource everyone! Excited to start this journey.