When it comes to Butane/Propane or CO2 extraction its pretty strait forward what methods you need to adhere by, due to the nature of the solvent. When it comes to ethanol its a bit different. I hoping to compile a list of all the major ethanol extraction techniques and why we use them. Now I know every situation is different and that seems to be what dictates why people choose their process. Hopefully this will help me and other navigate this simple, but easily over complicated process.

To get the ball rolling I’ll list the methods I have looked at using but since I have not performed any of these yet I can’t say which I prefer:

Delta Centrifuge Extractor - Off the shelf compliance, extractor and Centrifuge all in one. Expensive for its capacity and not really scalable.

**Pinnacle Extraction Skid" - Off the shelf compliance, larger capacity. Expensive, and still needs a centrifuge or Press to recover Ethanol.

Large Batch Reactor/Mixer - Custom built to size, reactors are cheap, can used with a blender style mixer to ensure saturation, easily scalable. Might not be compliant with fire codes or pier reviewed, Hard to filter biomass out of solution from ground up material, need centrifuge or press to recover biomass.

Mixer/reactor with filter bags of biomass - Cheap to set up, easy to scale, don’t have to filter out biomass, Don’t have to remove ethanol from mixer to add more washes. Hard to ensure saturation, need more expensive slowly geared mixer, Time to fill and un fill bags, May not be compliant or pier reviewed, needs centrifuge or press to reclaim ethanol.

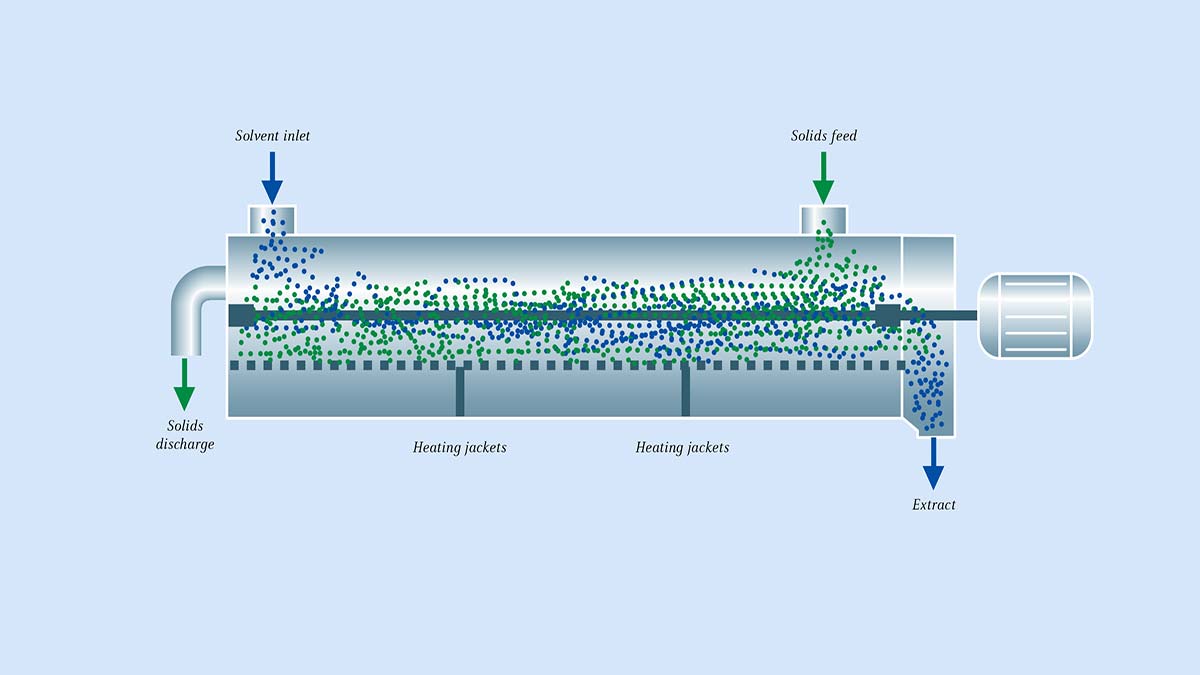

Spool Style Extractor - Cheap to set up, does not need electrical parts, can be run using compressed air or nitrogen, easily scalable, most efficient use of ethanol set up in counter current flow, possible to purge ethanol out of the material using air/nitrogen (not sure of efficiency. Most likely not pier reviewed, might not be compliant, time consuming to pack and unpack columns, might still need a centrifuge or press to reclaim Ethanol.

If you have other methods please add them, if you have worked with these methods please share your experience.