Hi Folks.

Anyone out there still using glass wiped film evaporator columns in their labs?

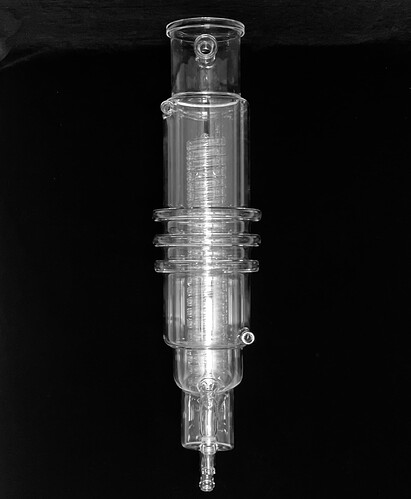

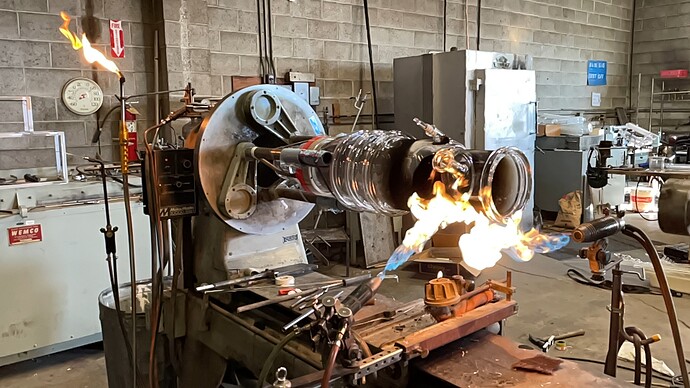

I build them from scratch in San Diego to fit into the generic Chinese set up (Y-Chem, Lab1st, Salem Sci, HiSen, etc.).

I’m looking for ideas for design improvement. I’d love to hear what you wish they did better and how that might work.

- Wish you could maintain the vacuum while swapping out the receiving flask?

- Thoughts on reducing or eliminating heat tape?

- Improvement to the standard o-Ring ball socket joint?

- Add access points for temperature or other data readings along the column?

Thanks in advance for your thoughts!

Regards,

Zachary Love

Stillworks Scientific Glassware

31 Likes

Thanks! I spent the past 18 months figuring these out…while the industry was switching over to stainless [facepalm].

Most labs still say the same things though - They love to see what is happening inside the column whenever possible. So I think there is still a future for glass.

8 Likes

That’s really beautiful work!

I’d love to have one in my lab, if only for the training/educational value.

5 Likes

Incredible work indeed! That’s no easy feat at all!

Could you help me understand how you ensure the wiper contact surface stays true with such a large piece? I can only imagine the long nights you probably spent dialing this in!

3 Likes

Hello Zachary, I’m Nicole from TOPTION, a factory located in China, we produce the glass type wiped film evaporator, about the design improvement, our engineers can support, welcome contact info@toptionlab.com to discuss more.

Love the scientific glasswork. Used to be that every lab kept a glass blower on staff and they were so valuable they were paid management rates. 6 figures back in the 80s and 90s.

5 Likes

Seethru is not required.

Heat transfer IS.

Glass is a wonderful teacher.

Stainless is faster and less fragile.

those are works of art.

10 Likes

Generally, the interior column is a single, original section of glass tubing. This tube is pulled at the factory from a large drawing towers and are generally quite round and straight. Additionally, I use Schott Glass tube, which has an excellent reputation for quality and tolerances. Even still, at 150 mm ID, there is going to be a little variation is shape.

Ill be honest, I build these to spec, but don’t know as much about the function as most of you do. I’m here to learn with the intention of improving the function.

10 Likes

damn man that’s a beautiful thing. you are very, very good at what you do sir. and i LOVE That shot of the cat <3

there are plenty of us that still prefer glass, don’t you worry. if i may lend my .02:

- most people do want to maintain vacuum while harvesting material, most of the time this is achieved by adapting gear pumps with check valves on the outlet to allow continous harvest while maintaining vacuum. if those are hemispherical joints on the outlets, anyone should be able to adapt those pumps to them, so it looks like you’re there already.

- the only way around heat tape in my opinion is more jackets (as per the VTA’s glass stills). i realize that adds complexity to the manufacture of such a piece!

- i’m not sure the O-ring ball socket joint needs improvement, in my experience it’s very vac-secure and the flexibility it allows for attaching a cold trap is very nice.

- access points for more localized temp readings would be dope, but a lot of us get by just fine without them.

cheers to you my friend!

3 Likes

We can fully understand that there are indeed some areas that need to be improved in the current glass molecular distillation on the market, but TOPTION mainly does stainless steel molecular distillation, which has a fast heat transfer efficient and automatic feeding and discharging design. The overall distillation efficiency is higher than that of glass of the same specification. An increase of more than 30% can perfectly solve various deficiencies. However, regarding your points of improvement, we have the following suggestions, which may help you:

-

When the glass receiving bottle is replaced, the problem of vacuum drop ---- TOPTION adopts gear pump to completely solve this problem, and realizes continuous feeding and discharging, without the need to replace the bottle. Of course, if you don’t use a gear pump, then adding a valve to the front of the glass collection bottle can improve the situation a little bit.

-

The problem of wrapping the electrical insulation tape on the outside of the glass. Regarding this point, the glass can only be used in this way. However, for the stainless steel molecular distillation of TOPTION, the pipeline is a double-layer thermal insulation type, and the external thermal insulation pipeline is also accompanied.

-

For the problem of O ring, they are currently using ball mill mouth and fluorine rubber o ring. After long-term use, the oring will expand. It is recommended to replace it with a mill mouth + PTFE-coated o ring, which may improve some conditions. TOPTION stainless steel molecular distillation uses stainless steel flange surface contact, and there is a stainless steel bracket in the middle of the oring of the outer PTFE, so basically the contact part with the sample is a small amount of PTFE contact surface.

-

It is difficult to measure the temperature of the sample inside the evaporator because of the high vacuum requirements of the system, but stainless steel molecular distillation can be used at the inlet and outlet of the interlayer pipe of the evaporator. Increase the temperature measurement point. The above suggestions are for reference.

Looking forward to your further discussion and cooperation with TOPTION on stainless steel molecular distillation.

Great feedback! I appreciate it.

VTA stills are apiece of art! Really talented work for sure.

Rather than a heated jacket, im gong to try a simple vacuum jacket. Without air to absorb/transfer the heat, I think dissipation may be sufficiently reduced…

1 Like

That’s an idea for sure. I will say that in my experience, when starting up a run (meaning, no heated material has run through and left some heat behind in the glass already) if a section of glass along the material flowpath is not pre-heated, material pre-heated to even 110-115C will very quickly lose the heat it needs to remain a fluid–and then, clogs, material backing up, etc. So, unless the vac jacket prevents this, it might actually get in the way of the heat tape one would need to keep material fluid. Just my two cents, again, take it or leave it! Just speaking from my own experience that it’s rare to be able to dependably run material over non-heated paths without congealing–however, i haven’t seen everything. vacuum jackets may well work so long as the material is heated enough prior to flowing over those sections.

That makes sense. The glass will act a a heat sync, at least until the heated distillate or waste brings up the temp some.

Another thing i’m working on is a little cozy (made out of heat resistant material) that zips over the joint. This will reduce hot spots (which exacerbate cracking or stress in the glass). The glass blower wants to improve longevity of the instrument and the distiller wants thigs to flowww!!

Thanks for the insight and thoughts!

Here is a tea cozy for reference.

4 Likes

i love it  i think those will make a wiped film look as cute as a wiped film could look

i think those will make a wiped film look as cute as a wiped film could look

2 Likes

Agreed, a vac jacket is unlikely to solve the problem imo.

Shit, I can’t get 1/2g in a non-heated glass cart reliably…(buy your carts a towel warmer  )

)

I guess the advantage of a jacketed glass wiper is you can catch the Marlotherm before it starts looking worse than your crude…

1 Like

had the same experience with Marlotherm. we switched to SIL180 by ThermoFisher Scientific and never looked back. it lasts forever, goes in clear and at worst only takes on a barely noticable yellowish tint, even after a year of constant use. never needs replacing, just topping off

4 Likes

Op’s post seemed like a good place to post this, huh?

1 Like

Thank you for the confirmation (and fix!).

I’ve long wondered if perhaps some hallucinating Wook had actually poured tails into one particular heat bath.

The resemblance was uncanny…

3 Likes