u need enough d.e so that its not sticky. i wouldnt do it in a flask i would start out in a beaker and then move dry it on a evap dish lik a pyrex pie dish. its tough to scale for the same reasons. need a lot of de and the overhead in your chromatography system

When the crude is dissolved in hexane then Celite sucks it up pretty well. It is pretty easy once you begin stirring to see if you need more Celite or not to get it dry. Stirring dries it then I let it evap in front of a fan set up for this. I use very small amounts so this works. Usually a final stirring is enough to remove all but trace hexane. This can be purged with vacuum but I don’t anymore. Stir dry is good enough and it packs better. Hexane goes through first anyway so it works.

All the crude is washed through with a solvent gradient and the stationary phase is normally discarded after use. It can be used multiple times but I normally elect to discard after a single use. I think it cost me about $15 for the gel per run. About that much too for the hexane and ethyl acetate combined. I saved the gel and dry it but have just kept the used gel stashed. This is why I do not always run it because it is a slight expense but when I am on a quest for some idea then it is a great tool.

Plus it might be the only way in my rig to hit absolute purity as I have discovered a trace compound that seems to transfer in the sublimator. DCVC removed this during this months lab so this might become an SOP if I see a repeat of this observation. The med sure seems Uber smooth this month after that.

So you could use any type of diatomaceous earth ? like food grade ![]() ?

?

?

I’ve tried this but haven’t tried Celite 545 yet. This Food Grade DE is VERY slow and for our purposes just too slow when you have several kilos of solution to filter. I have heard that 545 is a better choice though and filters faster.

I just restocked my Celite 545 from Amazon. The stuff is pretty cheap in the grand scheme of things.

From my order history. This seems to fill the bill for dry loading a DCVC chromatography column as well as general purpose “sand” for use wherever needed.

https://www.amazon.com/gp/product/B01MRZE7SK/ref=oh_aui_search_detailpage?ie=UTF8&psc=1

Cheaper in eBay, but sometimes ebay can be tricky

I currently use that bag of food grade DE. Works fine in my 5liter filter set up (it’s a big funnel)

Thx, seems almost the same thing. It just slower to filter I guess.

Read the fine print on that listing…it dont come in the container rather plastic bags…which is a bit suspect.

exactly…

Celite 545 is definitely faster. Way faster in fact, so much so that it makes no sense to not use 545 as it pays for itself in reduced labor costs rather quickly. I can rough filter (20 microns) at 48L/hr with a Celite bed, with DE I was in the 15L/hr range, winterizing is even slower, so slow that I ended up pouring out of my filter and using a different filter aid.

There are many types of celite brand de Hi flow celite then cell pure for final purity. Www.proof33.com

Thanks for the link. Thats really cheap for Celite

If I were to use a 5micron sintered disc, would Celite still potentially contaminate my product?

How are people using powders in CLS without putting powder into final product?

As far as i have noticed 5 mic sintered stops celite 100%

Not so sure about the silica60

And for sure it doesn t stop AC

But i have shown them beffore

Sanatary falanged 0.2um filter s

Are great i have one on a rig now for months and no isseus of clogging

You got a link for that 0.2 micron?

Seems like a tool I need, and all I’ve got on hand is the bucket full of spoons…

Edit:

So I should use the search bar…![]()

Found it! and you tagged me. Doh!!

That all depends on mesh size of the powders you are trying to hold back and the particle shape. Jagged particles tend to ram themselves together, while spherical particles tend to form a quicksand like mess. The key is placing particles that would otherwise get pulled through the disk on top of powders that can compact themselves and act as a filter for the looser smaller particles. Celite can work, but don’t really do anything for color. Bentonite clay fits the bill perfectly, and will contribute to the color remediation process.We offer the C.R.C in 2 and 5 micron.

Our quality control and compliance teams are analyzing Celite 545 offerings we are finding from other suppliers on the market. We’ve identified some quality concerns and suggestions to resolve them in an effort to ensure Solvent Direct maintains a catalogue of only the most compliant products at the most competitive prices available, we are hoping to get feedback from the GLG community…

If anyone currently using Celite 545 / diatomite filter aids has time for a phone call, we’d like to speak with you in exchange for free product.

Hit us at 1-833-Pure-Gas or on dm and ask for Brandon in Compliance. Thanks.

DEPTH FILTERS AND DIATOMITE PURITY

“…in analyzing filter extractables it is highly beneficial to study the components of the filter, rather than the entire assemblies.” (Jiang, et al., 2003)

There has been an extraordinary increase in the consump- tion of diatomite-based depth filters in biopharmaceutical production. All the major suppliers offer an extensive line of diatomite-based filters, including: Millipore (e.g., Millistak®), Cuno (Zeta Plus®), Pall (SUPRAdisc®), and Ertel Alsop (ZETA- PAK®). Nearly every biopharmaceutical company, globally, uses one (or more) of these products.

Because of the increasing interest in the quality of individual filter ingredients (Jiang, et al., 2003), and not just the finished product, the source and quality of the diatomite in these filters will be of growing interest.

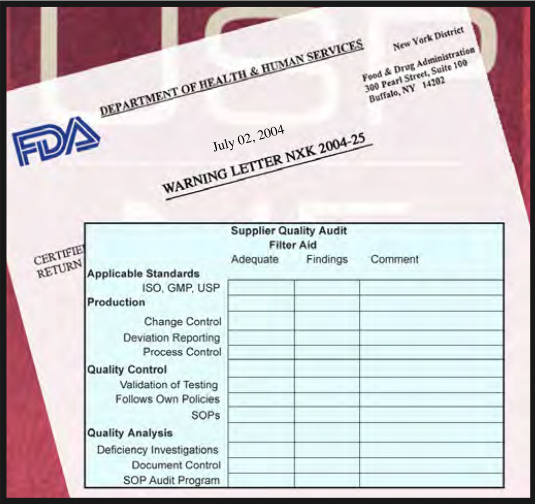

SUPPLIER AUDIT CONSIDERATIONS

“…suppliers are expected to use their special knowledge to make specific value analysis recommendation about materials, processes, equipment, and assembly techniques for any products and services provided…” (Baxter Health Care Corporation, 2001).

“A company that has never supplied a customer with strict GMP standards may require re-educating from management down to the operations level…this is usually a monumental task…” (Stephon, 2002).

“FDA considers auditing to be one of the most important quality systems. Current industry practice is to audit major suppliers every 12-18 months…” (Immel, 2006).

“When it comes to controlling risk and documenting decisions related to supplier management, FDA officials expect you to balance safety and quality…” (Avellanet, 2010).

“Handle audits based on risk level, audit frequency, and the supplier rating established in a supplier profile…The audit process, related audit findings, and subsequent supplier corrective and preventive actions (CAPA) must be managed and tracked…” (Jovanis, 2009).

"Meaningful dialog between the diatomite producer and the pharmaceutical user should be initiated with a discussion on how and why the diatomite is used (Kennedy, 2002; Stephon, 2002). Ensure that the supplier understands there are significant differences between Food Grade and pharmaceutical standards. Without this understanding an overzealous supplier may grossly overstate capabilities without realizing it.

Confusion will be most prevalent with a paper audit; it is essential that pharmaceutical companies visit the producing location, even if the diatomite is not used in a critical application. The potential for misunderstandings is so great that even “minor problems” can have substantial financial impacts (Stephon, 2002) and contaminate pharmaceutical production lines."

"Diatomite filter aids were developed for the beverage industry in the early 1900s, when the pharmaceutical and beverage industries used similar quality standards. Consequently, conventional “Food Grade” diatomite became widely used in the pharmaceutical industry. Even after the advent of the pharmaceutical GMPs, Food Grade diatomite-components1 continue to be widely used in the pharmaceutical industry.

This monograph summarizes widely held misconceptions on the standards of Food Grade diatomite. Several quality concerns are identified and suggestions are offered on how to resolve them.

There is often a misunderstanding that Food Grade Standards are adequate for pharmaceutical use. This is incorrect due to two major gaps in Food GMPs compared to pharmaceutical GMPs: (1) independence of the Quality Unit; and (2) change control. Further, an ISO 9000 Quality Management System is complementary to GMP, but not a substitute for GMP. (Moreton, 2009)

Another misconception is that conformance with the NF compendial specifications is all that is required. The General Notices of the USP-NF require that compendial products be manufactured to the appropriate standards of GMP."