So first please bear with me, I’m a noob when it comes to this stuff. Trying my best to figure it all out ASAP. Also sorry for all the text, tried to include as many pics as I remembered to take. Thank you in advance for reading!

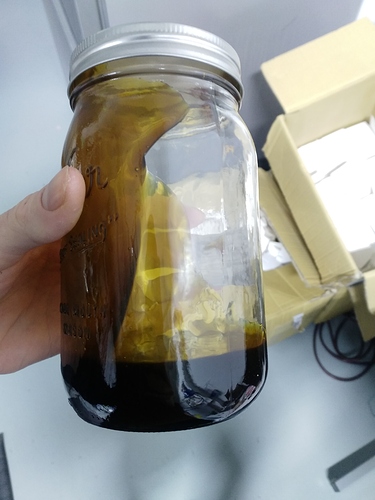

So I did an extraction on some pretty old (~7-9 month old) outdoor field grown trim. Not the best quality bio mass. Extraction was done in -80C ethanol, filtered cold, and rotovaped down giving this:

Side question - Is it possible to get EHO that when jarred up in bulk doesn’t look brown/black? Most of my extractions result in a nice yellow/gold color before solvent removal. Once in get it fairly saturated the color starts to get super dark and is always disappointing to me. When spread thinly the stuff looks ok, but still not where I want it to be.

Hence my venture into CRC. So I took a portion of the above EHO and dissolved it in pentane. Did LLE with pH swings (pH 4 brine, pH 8 brine, pH 7 brine). Seems I removed some impurities via the emulsions - specifically at pH 8 got some dark precipitate type stuff that I was able to wash out. But the aqueous layer never changed color, it was always clear, and the pentane layer was as dark as it started out as.

So then I did something which in hindsight was probably stupid. I took nearly every adsorbent I had (T5, T3, T41, AC), and added them to the pentane / oleoresin solution thinking might as well try hitting it with everything first and working backwards more methodically later. So I added ~5-7g of the above listed powders to my solution containing about ~20g of oil in ~500mL pentane, and mag stirred it for an hour. I realize my powder ratios are way off, but figured that more couldn’t hurt. Was really just trying to confirm that I can improve the color with these. After stirring for an hour I filtered the mixture over a bed of wet loaded celite on a buchner funnel. The color of the filtrate was unchanged. So then I said fuck it, cleaned out the buchner, wet loaded it again with celite, but then also wet loaded some silica chromatography gel (all in pentane). Didn’t measure out the silica, but I added probably way too much. I poured the solution thru this and was happy to find that the color actually looked great:

I don’t have a starting picture of the solution before CRC, but it was basically black.

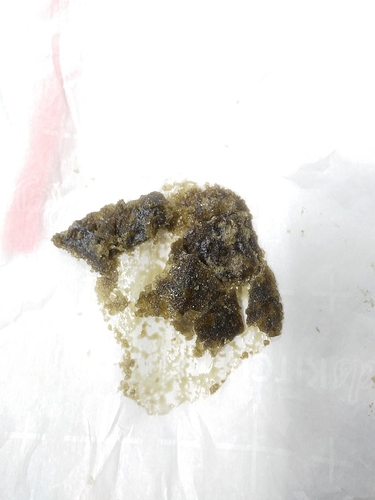

Upon rotovaping off the pentane I was left with this:

The yield was disappointing. I lost ~50%. I’m assuming it’s still in the silica which I didn’t flush enough. Or perhaps absorbed by the AC.

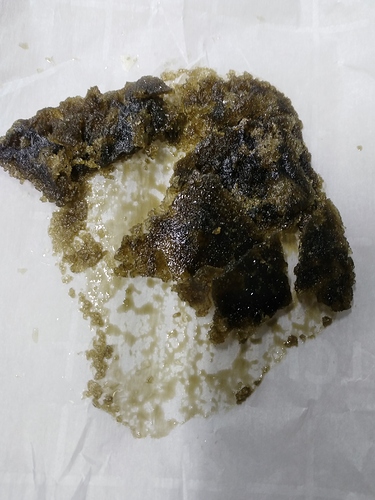

Shouldn’t have rotovaped it down so much and I had to redissolve in solvent to get out of round bottom. Used ethanol to remove it, added just enough to dissolve and then poured onto parchment paper and into vac oven to try and make pull and snap. Well, after 24 hours at 105F in the vac oven with full vaccuum running continuously at 40 torr or ~ 28.5"Hg (diaphragm pump) I got this shit:

Looks like maybe it sugared? What happened to the color? Did I possibly get some adsorbents past the filter paper and they "burned " in the oven? The stuff has a strange smell and a greasy feel to it. Maybe residual solvent? I’m at a loss. Gonna throw this stuff away and start over with a more methodical approach.

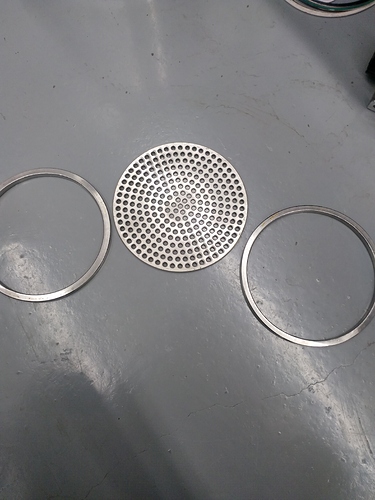

To compare, here is the same oil that I did no CRC to after the same amount of time in oven at same conditions:

At this point, I think I’m just 1 more fuck up away from just paying for a consultation. Need help with CRC ethanol, pentate, or heptane. Also need some help improving my distillations. They’re taking way too long. Also some other random stuff regarding ethanol extraction, shatter from EHO, etc. So if you think you can help, please DM me your rates and any other relevant info.