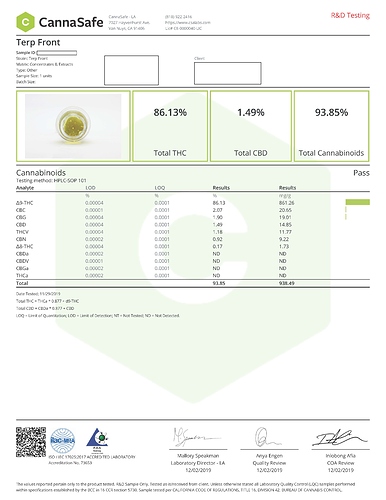

No 99% TAC guarantee. This is my SOP for mass production of market grade distillate. My results are usually between 89% and 95% TAC, which is fine for high throughput THC for the mass market. I don’t use any wet scrubs. When I used to run THC, my results varied from 80% - 96% THC (yes 96% is only the highest I’ve ever achieved). I decarb first to reduce total ethanol volume needed for winter. I’v found color to be material dependent and anything carbon turns my distillate red. I baby the fuck out of all of my units, I keep meticulous PM logs and plan rebuilds every 6 - 8 months. My highest TAC has been 98.8% (full spec CBD). This SOP is really for the UIC/Chemtech brand units because of the adjustment valve feature on the vacuum. Some of the notes and info added are my notes and some are from their engineers, Eric and John. This is for reading and critique purposes only, don’t sue me if you think my sop sucks please. Using these settings, all waste must be saved and re-run as the terpene strip will pull minors and some THC (Deep cut ensures a S1 to P2 situation will yield decent oil, again I did this to hit numbers - our waste was reprocessed on later dates when material was unavailable to keep things going.) I’ve attached a COA for the terpene waste re-strip/re-process to show what these “deep-cut” settings mean for waste reprocessing. I saved up about quarter drum of terpenes before I re-ran them and as you can see, it made some decent oil in regards to minors. I also do this because in my career I have fried 2 turbos, and I do everything possible to ensure there is absolutely no lights left to make it to my second phase. When I ran diffusion pumps I used to YOLO a lot of shit because those things are tanks and Terpenes don’t hurt them too bad. I’ve been running wiped film units for a little under three years now. I was taught by someone at my first job who left shortly after I came. We didn’t use consultants at my first job so this is part my knowledge, part their knowledge, and remnants of whoever taught my teacher in writing scraps left around our shop. I’ve used ChemTech rolled and wfe, YH chem wfe, and lab society short paths. Greenmachine, you’re welcome to take this and post it if you think its worth reformatting, again I don’t mean to hijack your idea.

EDU001 - Short_Path_Distillation_of_crude.pdf (179.7 KB)