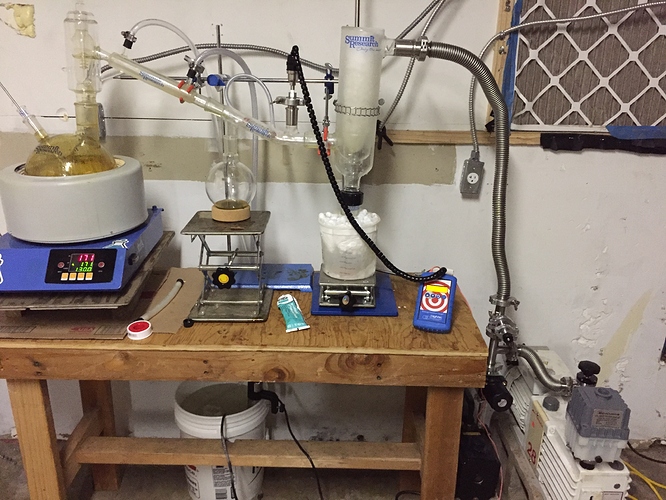

Hello there. This is my first time posting, I’ve been following the forum for a while now and the I think the open source knowledge is such a great thing for the community, glad to see it coming so far. I just came across a 5L full bore set up and am giving it my first go. I have about 1 liter of crude in the BF for my first run. I was wondering at what micron on my Digivac bullseye gauge I should switch from my wet pump (bhogart 15 micron) over to my Edwards28. Currently I am running with @112 pv /115 sv. My gauge is reading 286 micron. Thanks so much for the help !

Forgive me if this topic has already been discussed, I was browsing the forum and could not find it. If anyone can point me in the right direction that would be great! Thanks so much

once you are past your terpenes then you switch over

You switch more about temp then miceons. Im usually at about 30 micron on 1st pass and i switch from my sogevac to my leybold’s or Edwards around 155-160c eoght when the flavanoids start cause they wont nake it oast my cold traps

I guess my problem is since I’m only running a single cold trap I’m concerned I could toast my Edwards by switching to early ( which from my understanding is right around 170? )

Thoughts ? After my run I tested my Edwards with the digit gauge and it pulled to 14 micron

Thats good, those summit cold traps work great from what ive heard and the videos ive seen. I use stainless steel traps and 2l boiling flasks as my first cold trap and then only the stainless for 2 nd pass. Im about done with a run i take a pic and send it to you

Wayer wash ? What is that ? Damn that’s a big ass receiving flask I can dig it. Are you using ptfe around your kf 25 fitting in the second trap? WHy can I only reply once every day ![]()

I don’t usually use prfe tape but all my rocco glass was getting cleaned, and i had a leak so i taled rhem al

The tape on the kf25 fitting only have tape because the hose is the same size as the fitting so after heating i could only get the fitting in so far so i taped to prevent leaks. That 5/8 steel braided for 1st pass and 1” for sexond pass. Im putting together a 1” for first pass to.

Ahh I see. I ended up switching over to m Edwards28 at 204 micron, it was literally takin for ever to get any lower than 200 micron with this bhogart pump I had. It was my first time running the Edwards, before the run it pulled to 8 micron on vacuum test, and after it would not go below 14 micron when I tested gauge to pump. Is this normal pump wear and tear for a single run ?

From my understanding pulling volatiles into your pump oil will effect its ultimate vac depth. I believe folks usually run ‘sacrificial’ pumps on early fractions & a fresh Eddy for main body. If your budget doesn’t allow definitely stay on top of your cold traps, clean your glassware & bellows thoroughly, and change oil after your first pass.

Ok awesome can anyone link me a thread to a SOP on running a full bore ? I just wonder how fast I should go up at first, by a degree or two or by five or ten at first. Just trying to get the hang of this thanks for the help I’m a bit overwhelmed ha

Awesome advice

Pulling any kind of solvent or terpenes into your pump will keep you from reaching the vacuums ultimate depth and for that main body fraction you want a deep vacuum. When I did spinning band distillation I was below 10 micron everytime I was in the main fraction

Why doesnt anyone use stainless steel packing inside their cold traps?

Use a cheap short path head, cold trap and pump to get past volatiles before using the setup you have now for main fraction.

You’ll extend the life of your Edwards

You should be able to use the E2M28 for everything, just make sure you’re changing your oil as needed with quality oil (doing routine maintenance) on a regular basis. Oil is the life of your pump, same as your car engine. You can also open the gas ballast to help clean the oil and extend mean time between oil changes. Opening the GB allows ambient air into the pump which makes it run hotter literally boiling some of the contaminates out of the oil. To do this, close your vacuum valve, open GB 30-60 minutes, then close GB, open vac valve and let pump return to base pressure before continuing with your process. Ancorp makes some nice stainless cold traps, both LN2 and simple dry ice versions. FYI.