I actually don’t sell carts, and do not make recommendations on which carts to use. Although I will say the new style tamper-proof snap-fits are 100% the way to go for automation purposes.

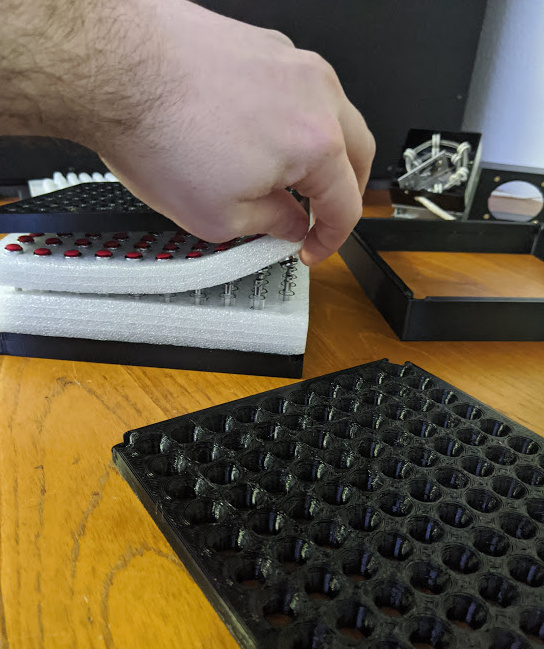

In a box inside a foam tray but the rubber gaskets need to be removed with ikrusher hardware?

which companies support your tray plug and play system since thats how your selling it?

I’m not sure about iKrusher, if you snap a pic of the empty tray I can pretty much tell visually if it will work or not. It will not automatically remove rubber gaskets for you however.

I’ve come across less that are un-supported than are supported. As long as they are shipped in a roughly grid-like pattern in foam, the system can accommodate the tray automatically. The software currently does not support offset grid patterns like are seen in some all-in-ones.

the software automatically scans a grid style layout and can create a fill program based on the scan or does this all need to be programmed?

is this all part of the 2 hours too>

how many vape jets do you have in labs now? how many units have you sold?

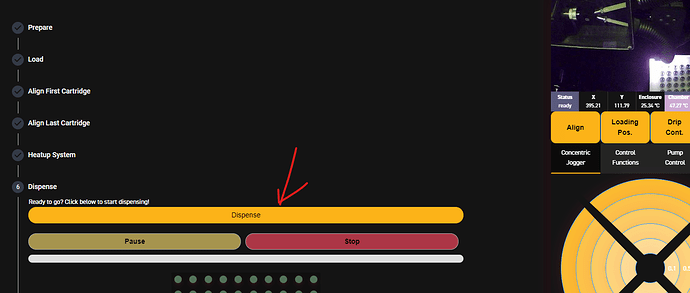

Yes… Exactly… You tell it the X & Y dimensions of the tray. For example, 10x10. You then show it where the first and last cartridges should be “roughly” located. From there, it will scan the first and last positions, calculate a grid of 100 and overlay it using those two points, then during the move to each point on the grid it automatically aligns to that specific cartridge to account for variability. It then measures the center post to side-wall offset and calculates the best position to place the needle.

This is all automatic, and does not need to be pre-programmed.

Once of my favorite trade-show tricks is telling the system to dispense a tray of 100, then while it is dispensing poke and prod and move the tray. You can see the system re-calibrating and re-aligning in real time. Even with an asshole human trying to mess it up, it always gets the needle in the cart.

you have any videos of this all happening. i mean a picture is worth a thousand words and a video is worth a million.

so after watching the videos i dont know how your gonna fill that number of carts without having someone in front of that machine the whole time its running…you might be able to get away for a minute or two per tray while its filling but your gonna need a full time monkey manning the machine.

if you had a press for the tops. I can see that person being able to top the carts too but doing 6 hours worth of other focused work looks like a fetch.

Sooooo…id say you need a $20 employee for 8 hours for that 4000 carts. As i would not let some minimum wage worker playing with what looks pretty technical.

probably vs someone that needs $15 for 2500 carts. in that example the ROI is much greater than a year.

It is literally take off old tray, put new tray on, press button. Come back in 10 minutes and do it again. The entire process takes ~60 seconds, but I accounted for a full 2 minutes.

When not changing between cart styles, operating is a single button. This can / should be done by a packaging employee, but in my ROI calcs I used a lab-tech.

Really, it is a single button…

Press button, get carts ![]() Put new carts in, click button.

Put new carts in, click button.

I have customers who would completely disagree. Your productivity will drop immensely the first few days, as people crowd around and watch it run. It is mesmerizing. But after a while, the novelty wears off and the only time you pay attention is if the light is green, indicating it needs to be loaded.

its private…

Sorry, was still processing when I hit submit ![]() Refresh the page.

Refresh the page.

super sweet ryan! i still think you want someone to monitor the machine.

That person could be monitoring, and folding boxes, or capping, or packing columns at the same time. That is the main idea with the LED indicators, be in the same room, but honestly go about your day occasionally feeding it carts ![]()

Thank you ![]() I’m a bit passionate about this system as you can tell. It’s been a labor of love full time for over a year now.

I’m a bit passionate about this system as you can tell. It’s been a labor of love full time for over a year now.

Looks like a nice rig. From the videos I gather that you just slide in the foam squares that the carts come in. The machine scans and maps a grid then gets to work. The machine also cold fills the carts? The million dollar question, how does it cap the carts?

The guy with the other 9 mins can cap

The $.02 answer: it depends on the style of cartridge. I managed to make a machine that can fill just about any cartridge, but capping is a much more difficult process and changes with every style of cartridge.

We have alignment jigs, presses, plates, and other stuff to assist with capping depending on the hardware used. We have only been able to get batch-capping successful with snap-fit tamper-proof carts.

I have a external solution that successfully caps CCEL style press-fits, but it is over $10k and requires 16T of force.

I am currently working on an alignment jig for capping the iCell ceramics as we speak. That is a 100 at a time operation.

For example, this plate system is used for snap-fits from BeGreen Supply. It can cap all 100 at a time using a 1.5T press.

Nearly correct. It really scans / maps as it goes. It scans two edge cartridges to build an initial grid of points to start from. It uses the pressure equalization time on the plunger pull-back to perform the cartridge alignment process.

Depends on what you define as cold. Typically around 50-55c

My average cost over years on cart filling has averaged out to around .30c. This is not counting putting orders together etc… but does include two quality control checkpoints tracking manufacturing etc.