Maybe not the right spot for this but

I really start believing that the faster vapor is condensed or removed from the system the lower the average vacuum of a proces

Several by accident story s here on the site Where what seems an overkill of pump cappacity Some how gave better results

Thats how @anon42519203 was doing his, mabey he can chime in.

Once cfm flow is gone molecular flow comes into play, the name of the game is pushing molicules tward the mechanical pump and out of the system. Diffusion and turbomolecular pumps are used in UHV systems specifically for this purpose. An array of mechanical vacuum pumps may work in a slightly similar way, but not as effectivly as the turbo or diff pumps.

https://www.pfeiffer-vacuum.com/en/know-how/introduction-to-vacuum-technology/fundamentals/types-of-flow/

I’ll do a write up sometime this week and post the basic code. The arduino uses a wrapper around c/c++. Its very easy to learn and if you have any c/c++ experience you should be good to go.

Yes, the mks 901 uses a non handshake rs232 or rs485 protocol depending on the sensor features. You can definitely hook it up to a computer and not have to use the arduino. In fact that’s how i initially tested the sensor. The documentation on mks 901 is pretty good.

I already ordered an arduino mega kit to learn it and I’m sure it will come in handy for other tasks (I would like more control over the PID). A lot of good cycle timers or automation systems are significantly more than an arduino.

I’m guessing you can just take apart a DB15 cable and then use a multimeter to tease out the leads and hook it straight into the input pins on the arduino mega.

No, you can’t hookup the hd db15 directly to the arduino from the 901. The arduino uses ttl serial and the logic voltage is incorrect for true rs232 communication. You need a converter. I used a MAX3232 from sparkfun to make the conversion. The breakout board they have will allow for 2 sensors.

I got my arduino kit and I’ve played around with it a bit. I’m stilling waiting for the max3232 and the 901k… Oh yeah and the kf fittings and such to hook it up! It seems like these projects always have so many pieces ![]()

I could see how you could make a super PID with the arduino pretty easily and it would be about the cost of a PID I think. You’d just need a solid relay.

Ya, there’s always little things that one forgets with stuff like this. It normally will extend the completion date out at least a week or two further then expected. I just add that extra bit time into the project timetables now.

I made a PID with an arduino a few years ago just for shits and giggles. PID’s are really affordable though and outside of the ‘fun’ of doing it theirs no real benefit to it. But if you’d like to understand how PIDs work its a great project.

I’ve been using arduinos for some time now. I’ve built a fully automated air ride controller for a hotrod of mine before I could buy them or more accurately before I could afford them… Think accuair, ridetech, etc. Its still going strong after almost a 8 years now. I’m pretty proud of it really.

Just a small update on the Vacuum gauge/controller write up. I’m working on it, just be patient. I’m about as busy as one can be right now, but i really love this kind of stuff, so i’m making time for it.

I also ordered enough stuff to put together 5 pre assembled vacuum gauge/controllers for people that may not be able to put one together themselves. I’m not sure how much right now, but they wont be super expensive. Probably in the 200-300 range. This will include everything EXCEPT for the 901 sensors. They will support 2 sensors simultaneously and that’s about it. It wont have any previsions for turning equipment off and on, but if someone wanted extra features I wouldn’t be apposed to adding them. No pre orders yet, until i get the build finalized. I would expect it to be sometime mid December before anything happens.

Found a good link to more info on these 901p sensors!

http://www.fusor.net/board/viewtopic.php?f=10&t=11533&sid=f9ab5ed54cc431548b9fec1aa3e7bb45

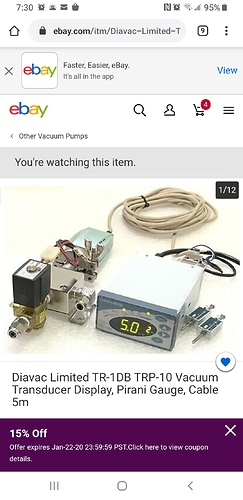

Any of you guys using a surplus biotech setup like a diavac TR-1DB and pirani TRP-10 transducer? These go down to .05 pascals which is like .4 micron or so. I don’t know much about the TRP-10 series transducers or how they compare to a micro 901p transducer

Is there a need for some cheap digital gauges? I have a team looking for another project as development has mostly finished up on our autofiller.

I have been looking for some other automation / product ideas, and would love to find the next project for my team =)

How about some cheap gauges that read different rs232/485 sensors and data logging

Reading different sensors is a software development nightmare. Would be better to create a driver for specific sensors or sensor series.

I’m willing to tackle it and open source the result if there is enough interest. Been looking for a side project!

Is there a specific sensor the community would like a quick and dirty gauge on? Typically I build 100% without a display or buttons and just make a web-app for controlling the device, but it seems like a cheap screen would be needed for this application.

I’ve used one of these gauges for 2 years and checked it against more expensive models. It’s always been similarly close and has been a great cheaper option.