Hey Guys,

We are currently working without vacuum controler. These months I see more and more people using this type of controler : https://www.acrossinternational.com/DigiVac-StrataVac-Regulation-Kit-for-2-Head-Distillation-w-WiFi-StrataVac-2HeadKit.htm

So my main question is to know if an ideal vaccum exist for every fractions ? And what will be improve when we control the vacuum ?

Seen on BVV video on youtube it goes from 4,5 to 3Torr during the head then 0,5 to 0,1 Torr during main fraction.

Have a nice day from

1 Like

I first of all would not call it a. Controller but a gauge

The controlling functions that can be placed don t have a function in spd

As a gauge it seems ok yet I could not find the limits of measuring vacuum ,deep vacuum

Most sensors have VACUUM field they are presice in measuring vacuum in

As for setting a controller on vacuum in spd makes not much sense since I always want to go as deep as possible pushing my pumps to their limits with a frequencie Controller

Which is different

Holding a steady vac would have an advantage for the boiling temps would become predictable but the question then rises as to how this is held some keep a steady vacuum true a needle valve which ads air to the system which is not good

You would then need to make sure it ads an inert gas to the system

I also find that the mechanics in controllers always run behind on response to keep the pressure steady and with a unpredictable boil

As first pass they can t keep up

So if the gauges have the vacuum spectrum you need yes seems ok

But if ever you plan on hooking up a diffusion then have a good look if those levels are included

1 Like

I and for that money there are a lot of equally good gauges for sale on eBay if not better

2 Likes

Hello @Roguelab thank you for the time you take to reply to me.

That’s what I basicaly thinking. Deeper as possible on my SPD. So I’ve better to put my money on a fraction finder from summit finally right ?

Hmmm now there I can t help I have never worked with one and the posts about it differ some like it some don t

What setup do you use ?

Laminar flow ?

Or cow ?

How hot is the condenser set ?

1 Like

Will be a SPD with PTFE valve, no cow. Same as 10L AI.

We usually process with cow on small SPD but new setup is coming soon and I’m searching for all the lasts update regarding the efficence of the process. Vacuum controler finally appear as not efficient as I supposed.

Currently very strict SOP’s looks the better solution combien to :

- Cup Style conenser

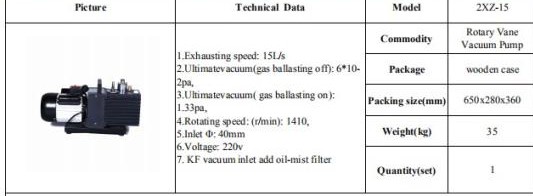

- 15L/S Vacuum pump

- Doomshield

- PTFE valve to avoid cow and contamination

Hmmm so you mean the 10 liter spd from accros international with 2 heads ?

That is vapor dinamicly a tough setup

You really need to check vac lines length etc etc

The path of least resistance comes into play and to have a even vac pull on both ports won t be easy

1 Like

Maybe that is where the vacuum controller comes in.

1 Like

Yes we gona have a 2 head, but maybe we will work sometimes with one head, depend on the volume we have to ditilate.

So maybe in this case a controler will be important as @blackie said. Will check it more deeper if I can find solutions.

Tank you for you help !

2 Likes

I’m just guessing, but that was the first thought I had when Rougelab mentioned the issues with dual heads. I had never thought about that issue before.

I was wondering what kind of applications a vacuum controller had in spd. I’d be interested to know what you learn.

I was thinking the application would be something like this.

Remember. When talking SPD you never ever really ever use a controller. You only need to do two things.

-

Feather the vacuum in between wet vacuum and dry vacuum.

-

Full bore no holds bar vapor down the pump throat. You never ever control vacuum with a set point. You always want vacuum to be at it’s limit so you can lower the cusp of the distilation as low as possible.

Some dont want to hear this but I developed the dual vacuum guage sensor Wich was originally called the svc-3 and this was developed with the stratavac components with digivac. Tim Collins can validate summit was the first to develop secondary and tripllete vacuum sensor arrays.

So I can deff guve you insight what this is used for. Summit was the first to create these setups and for good reason.

-

First guage tells you rough estimate what molecules are shooting past the sensor to give you general SPD readings. None of these are anything over than objective to your process. Meaning sod readings are only usefull for pot pressures. Not health of system or anything that tells you how a spd is running. That’s determined by pump guage.

-

Second guage gives you the pump curve reading. The second guage is the most important. People think the SPD guage is important that is actually just a rumor spread by others. Also the sensor at the pump will tell you the health of the pump from when you engage it you should have a text book stepping when the reading hits.

See the short path will always have a variance. That variance is not important. Sure it tells you some good info but it’s almost useless.

The pump when you peg it all the way. Will always have a more accurate reading because there are denser, condensed molecules heading down that path.

See a short path can always opperate say at 40 microns in the pot. However at that range the pump can say 2 microns or 8 microns. Whatever it may be. . When you see during opperation the pump curve on pump down being affected or the microns climbing run after run on your pump it’s a indicator of the pump health.

Remeberberry the guage at the spd is objective knowledge of what’s going on inside. The pump guage is determined how healthy your vacuum is and what condition the pump is in.

Running a guage on each side like in dual head systems is pointless. You want to get the reading on the side with the lowest distance to pump and then Use second sensor at the pump.

We developed this about three years ago. Across and others are just learning about this. This explanation shows we pioneered the multi point arrays and this was how they we’re engineered to be used.

Without a pump guage you will always be running blind. It doesn’t mean anything since the pump can be anywhere and the system can still be sitting at 50 microns.

Good tip. Depper pump at opperation better process. Thats why we watch the pump. To see what’s happening at the the throat and how the pump and over coming the boil off effect.

11 Likes

The ultimate vacuum at the pump will always determine how low the cusp of the distillation for vapor pressure/lowest temps etc… Available in the system. The sensor at the pump is your most important sensor you use on the system.

7 Likes

@spdking thank you for these precious informations. It take me time to understand everything but the big point is I need a pump as big as I can

So I’ve choose a 31CFM one and I’ve don’t take the vacuum controler. Only 2 display vacuum gauge.

Thank you again and have a nice day.

Try to avoid those 31 cfm import pumps. They aren’t eh same as the Edwards.

1 Like

Yes I will go for an Edwards as soon as possible but have to go first with these 31CFM pumps.

What pump are you talking about exactly.

This one with KF25 and Oil Mist.

This is the cheaper version made by woosung. Then all to another company to apply the unsafe motor. That motor is entirely unsafe to use.

The front end is a woosung unit. With correct motor from woosung this is a 900 dollar pump (white labeled) I believe. It’s substantiate cheaper with that motor.

1 Like

Are these like all the pumps companies like xtractor depot(xeno) and USAlab are selling? Im sure you have your opinion on those pumps?

Yes. XD buys the pump for about 800 private labels from woosung, you can call them they will sell you direct. And it’s about 100-150 to import it. It’s a low quality unit in my opinion. It has a very weak pump curve.

I am very familiar with them.

2 Likes

![]()