I am working with a 50L USA Labs Reactorwhich continues to leak after Ive thoroughly tightened all connection points. It doesnt leak much overnight at room temp so it has to be a problem with the viscosity of the glycol heat transfer liquid at the temp Im at. The problem is I cant figure out how to properly drain my system of heat transfer fluid so that I can replace the seals. Also I dont see any noticable defects in the seals so part of me wonders if replacing them will have the effect Id like. If anyone knows of a sealing compound I could put on top of the seals to have a quick fix for the time being that would be huge but Im not sure if something like that exists. Im using Duratherm G-LV Low Viscosity PAG Based Heat Transfer Fluid at 130C.

I use red automotive silicone and have never had a problem. It’s good up to 500f I believe

You’d drain it at the TCU drain port and get that to a location lower than the jacket.

Just cover the seals with it? And any chance you know if its usually stocked in any stores?

Sorry still learning the abbreviations, is that the drainage port on the heater?

Any automotive store should have it

I’d take the seals off and put a small band of it around the class then reattach the seal. Let it dry 24 hours and you should be good

You can also try to squeeze some into the spot where it’s leaking it probably won’t work as good as if you took the seal off though

Yes heater or chiller or combo unit whatever recirc you have

I have also used the red automotive high temp silicone sealant (AKA gasket maker) to successfully fix leaks.

I had a Chinese rotovap bath that leaked through the passage for the heating element and the silicone fixed it perfectly and held up for a year until I scrapped the entire roto.

Definitely check into the compatibility of your heat transfer fluid with the silicone (it’s probably good).

Also figure out how to drain the fluid and dry everything off nicely before applying the sealant and give it the proper time to cure before re-adding fluid and heat.

Thanks for all of the tips Im gonna definitely get the auromotive silicon when I manage to get this thing apart and replace the seals.

Also, just today a major leak formed from above the lower connection points but well below the upper port. Its very strange because its a consisitent flow which can be missed but the leak doesnt seem to have an origin. Its literally coming from the base of the neck between the reactor and the spout (right where the reactor glass curves towards the neck so still well about the seal that is below that at the neck). Have any of you ever seen a reactor leak from micro cracks? I got this second hand and there is a decent chance the previous owners were hard on it so thats why Im thinking it could be a crack. Ill send pics shortly

I sent this to @usalab . Wondering if you’re seeing the leak at a lower point but it’s coming from higher up? Can you fill the vessel gradually to see the level of the leak?

I should clarify that it is the heat transfer fluid that is leaking. The inner vessel is still perfectly sealed and I have not had any issues with that thankfully.

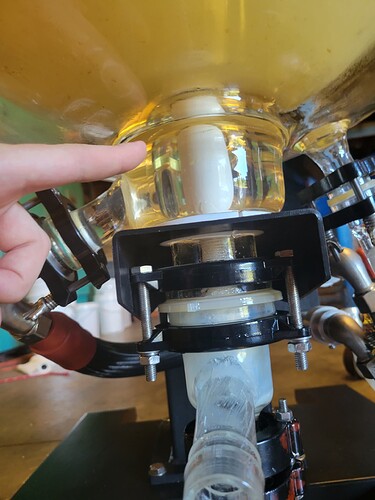

Here is a decent picture. Its coming from the bend in the glass at the very top start point of the neck, where my finger is pointing. Its running down onto the black metal plate and dripping off of the plate. I have checked all placed that could be leaking heat transfer fluid for it to then run down to that point and they are all solidly sealed and not leaking. There are also no trails of heat transfer fluid leaking down the side that could be causing the illusion of a leak originating from that spot. Its making me feel a little crazy unless there is a possibility that there is a micro crack right there, but you can see the shear volume of leakage in the video is not what Id expect from a tiny crack.

When you tightened down the bolts to connect the lines to the glass ports on the jacket, did you use a caliper to ensure you’ve compressed the gasket evenly at all bolt locations? Usually its like 3 bolts, and you take measurements at each bolt location to make sure they’re within something like 0.005"…even 0.010" would be decent. Similarly, a torque wrench can get you pretty close.

Also, is the weight of your hosing supported or is there force being put on the flanged connection when the hoses are full of fluid? Either of these two, combined with heating/cooling cycles and reduced fluid viscosity at temperature could result in a leak.

Can’t say for sure but that drain port support plate is a flaw in the design and very much prone to breaking and cracking the glass there. We usually remove the body and add a rubber seal in addition to the PTFE for extra cushioning.

Looks like the silicone gasket between the drain and kettle body is swollen AF? Atleast it kinda looks like that to me.

Id replace the gasket with something compatible with the solvents you are using.

I personally like the “envelope” style ptfe ones!

Whatever you do, don’t over tighten the bolts!!! I’ve had a few of those cheap USA lab drains Litterally shatter and disintegrate my hand. Not fun. They weren’t even super tight, just cheap glass.

Am I hallucinating that there are more than 2 jacket parts on that device?

the other is for pulling vacuum. The outer layer is vacuum insulation.

I don’t have access to calipers so I just made sure to tighten them all evenly. That being said who knows if they were evenly tightened to begin with so that will be the first thing Ill check. The hoses are not supported by anything specific but are touching the ground and seem to not be pulling downward on the joints much but I will also try and get something to support them right at the joint so they arent applying any force at all. Thanks so much for the advice!

Yah its been that way since I got it I was wondering is that was a design aspect or something was wrong. Ill try loosening it up and maybe that might let it slide back into place.