A few of you have probably figured out that I’m more than a bit of an electrical nerd by now, well, one of my clients has been having a lot of problems with a large 85 kW water cooled Lneya/Shivhem chiller and aside from a bit of a refrigerant leak, most of the blame falls on bad design and implementation in the power control for the compressor.

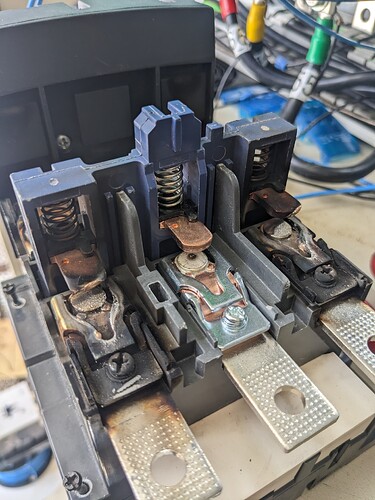

First, some carnage!

This is a contactor with less than a week of runtime on it, and as you can see, middle contact blocks are in fine shape and the outers got blasted, melted/ejected some copper and are well on their way to letting the smoke out.

Someone else had messed with it before me, but if you’ve got any problems with a matched set of contactors that drive a star-delta motor starter system, REPLACE ALL 3 AT ONCE. This individual replaced 2 out of 3, and the same problem happened again, likely because there was a problem with the star contactor which goes first (shorting all 3 windings together) before dropping out seconds later and (hopefully) starting up the motor.

And I could have done that, but this customer doesn’t want to screw with blown contactors and downtime every few months, and frankly this could and should have been done better from the factory. So this is what replaced it, a soft starter, wired inside the delta winding, the PLC and ice cube relay wiring changed to not pitch a fit over only having to trigger one output and no more big contactors. Estop and power switch on outside panel both shut down the soft starter alongside the PLC and HMI.

Another nice thing that the factory never bothered with, is that the soft starter monitors and displays running amp draw whenever compressor has been commanded on, and shows it on the display. For now this requires opening up the cabinet door, but we’ve ordered a door relocate kit and cable from the manufacturer so that it can be mounted right next to the HMI so everything can be viewed from the outside without opening it up.

To make this job a bit more difficult, the OEM either doesn’t have or won’t share wiring diagrams for these things. Assholes. Without their help, I built my own for how it was from the factory, as well as how it is wired now with the soft starter.

Pic shown without all the cable tray covers on as someone else had lost a couple of them, but they will be replaced next time I’m on site.