Thanks everyone, one final question. What temperature parameters would you recommend for my terp and cbd pass? I saw someone above suggested a higher column temp for the terp pass so now I’m curious if I should change others too. Thanks again!

The vacuum levels during each pass are tough to nail down. Delta’s system doesn’t give units on the control panel which blows my mind! For the terp pass, we typically see about 2x10^-1, and for the CBD pass we typically see 4x10^-4. I presume this is torr/mmHg but since they don’t explicitly tell us anywhere, it’s difficult to know. These vacuum levels were the levels recommended to us by Delta’s training team.

Rolled film is different in operating than a wiper. Make sure you put a temp probe in your hopper to make sure temperatures are equal before operating.

What delta calls their RFD is just a standard wiped film with rollers.

This isn’t similar to chemtech?

It’s similar to what chemtech calls their short paths. It’s not similar to what chemtech calls their rolled film. I know, it’s idiotic. Both of their naming conventions could use a little work.

I started researching these systems when I first ran the chemtech. The petro world classifies them as short path evaporators. Than depending on the the blade. It’s agitated or wiper. The rolled film if I remember correctly start pushing out at higher speeds but the inner jacket starts pushing out wards also? So technically they aren’t wrong. I do know they had a rumor out here in Santa Rosa that delta is pushing 6L an hour. No matter what the crude is. I got the opportunity to talk them at my old work. I asked them array of questions. They didn’t confirm this verbally but they smiled when I broke down my theory to even reach that output. I don’t think they are rumors I believe it’s true.

Basically, what we call wiped film is really short path. But people were familiar with the popes, which use wiper blades, and called them wiped film. Then delta made theirs with rollers and decided they would be fancy and call it a rolled film instead of a wiped film.

On a parallel track, Chemtech made a line of machines with rollers and called them short paths (which is what they are). They also made a line that used an external condenser, and called those rolled films.

End result is Delta’s “rolled film” is basically identical to Chemtech’s “short path”. Meanwhile Chemtech’s “rolled film” is something entirely different, and rarely used in the cannabis industry.

Those look good, and your temps look like they’re probably good for those pressures. Do the things mentioned above for a better decarb and clean your internal condenser and report back after your next run.

This thread might be of some use to you. You do need to figure out what unit of measurement the vac gauge is in. Could be mmHg/torr or microns of mercury. This is my uneducated opinion, but I would guess the boiling point of CBD to be 450C plus or minus 15C at 760mmHg. Knowing that might help you make adjustments for distillation temp at whatever vacuum depth you are pulling - after stripping terps.

I’ve never distilled before so take with a grain of salt.

If i remember correctly you operate a chemtech. Do you startup the same way as a wiper film? Somebody showed me the good life sop for wiper film a few months ago. The start up procedure doesn’t work for the RFE at least it didn’t for me. I tried it when I first started operating the chemtech. The initial startup cut isn’t heads. This is just impurities that are splashing from an uneven coating of the rollers.

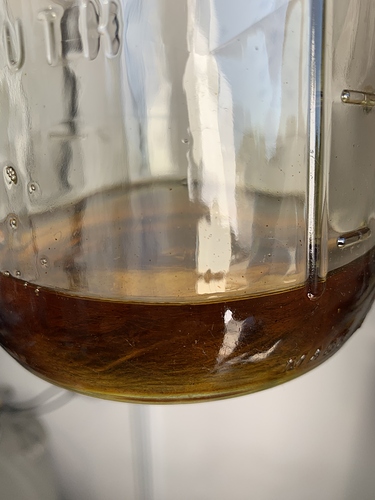

I decarbed at 130 C, pulling a vacuum of 25 inHg or greater for nearly 4 hours(it decarbed at 110 C for an hour before I switched it over to 130 C). The terps started coming out beautiful in the RFD but towards the end, the started getting dark. Is this normal? It didn’t look like our usual result, it doesn’t seem any crude made it in with the terps. I have attached pictures for reference.

I have used a chemtech short path, and it runs pretty much identically to a wiped film. Never used the chemtech “rolled film” (i.e. with external condenser).

What’s the extraction method for your crude?

Before saying its over a year old, remember that I would be told to search topics before posting a question or problem that exists on the forum.

We purchased this unit second hand. I did not receive the class from Delta and I have figured out a decent amount through trial and error. My question is have you found any base numbers to start off of that you can adjust from?

The settings I am using on my Devol run are as follows:

Feed Column - 100C

Roller Column - 100C

Condenser - 30C

Feed Rate - 1000

RPM range - 500-575 on material

Vacuum - 1.0-2.5 x10 -2 mbar

First pass run:

Feed Column - 110C

Roller Column - 180C

Condenser - 100C

Feed Rate - 800

RPM range - 700-750 on material

Vacuum - 1.0-2.8x10 -4 mbar

I don’t want to assume I am getting the best results I can and just wanted some experienced folks that could critique numbers and just to give me some closure on this machine and how best to max out my yields.

I don’t know if you have access to short path’s but what we do is pull the heads off of the material in the short path, then put into a bucket in order to feed into the RFD later. We have had a lot of success with this. It makes it so we can run the RFD close to 16 hours and not have to change out the cold trap. This makes it so we can pull heads off while simultaneously running the RFD to distillate. We have had success with running the roller column at 167C. Good Luck

No short path yet. Money, space and time right now.

My last material had so many volatiles that I am running a third pass. Really isn’t worth my time, but I am required to hit a % yield and hell or high water, I’ll hit it. I’m at 165 and have similar on the cold trap to your first go. FML

have you tried turning that heat up, on evaporator and feed tank? if the feed line to the evap wasnt so short id suggest wrapping a section with heat tape to preheat that feed as close to evaporator temp as possible but it doesnt look like ya got room to do that with their feed tank configuration.

180C on the heater doesnt mean your film is getting to 180C

@190, I’ve had to pull the column multiple times to remove cooked residue that stuck to the rollers. In fact, it acted like glue and held them firm against the column, making quite a bit of noise, thankfully not flattening the rollers. Different material, different runs, all the same results.

I have had pretty good results at 185, but felt like I was rolling the dice that close to the failure point at 190.

Thanks for the ideas and feel free to keep them coming.

oh damn that sucks, thankfully it didnt screw the drive assembly up. So as soon as feed hit the hot evap wall with rollers rolling it stopped and gummed up?

Whats the crude like? must have alot of polar components that if removed would help out in more ways than one. Its a worthwhile effort if they are high enough to be causing issues like that.

Is the feed tank agitated?