All our company does is remediation. Recently we have picked up a few more pieces of equipment in each for reduced rates or free remediation monthly. Wondering if anyone else has extra equipment we could use in exchange for our service.

What do you need? What are your bottlenecks? Where are you located? What is your current capacity? Pricing schedule? What form of remediation are you employing? What kind of COAs can one expect back after your service is performed? Can we see an example coa and photo?

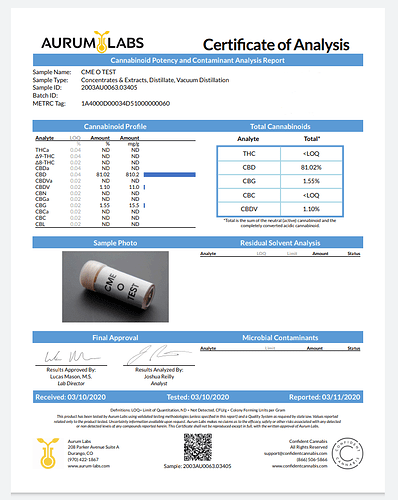

I could use more rotos or a FFE, also more chromatography units and reactors for isolation. Bottle neck would be solvent recovery right now but I’m working to get a FFE which would mean more chromatography and isolation. Current capacity is 10kg max 8kg normal input per day. We are not doing anything special. Just normal reverse phase chromatography. We are able to get THC levels below 0.00% but more loss does occur, typically we set our limit with customers at 0.08%t with 80% return. We have ability to leave what ever amount of THC you desire. We also powderize all of our finished product. We have tons of COAs and I’ll post pics too.

When you say powderize the final product do you mean that you allow the distillate to crystallize and then you grind and pulverize it foe easier handling??

That’s exactly what he said and exactly what the pictures show. I know this for a fact as I have two things going for me here in this situation… I can comprehend the English language, and I can see the images displayed in front of me on the screen.

At least I think so… @THCremediationam I right or did I completely miss the mark here?

Its exactly what he says but I prefer not to assume and ask for confirmation as its a great idea and would make handling much easier.

@THCremediation If that is what you are doing do you care to share what kind of grinder you are using to get this broken down?

You guys are right. However simple the process may seem it took a lot of time and effort to get it to a production level of simplicity and flow. Due to my responsibilities to the company I cant give away process, but I can tell you companies are paying me more for this becuase it saves them days of heating and homogenizing. It is so much easier to work with. So who have some extra equipment and wants their oil to look like this?

Thanks for sharing and I understand your IP is exactly that. Great idea!

Meanwhile people are melting down their isolates and calling it distillate cause they thing people want oil and you’re over here breaking boundaries and exploring new worlds with your grinder IP I love it

Are you guys using ln2 to freeze while grinding? Moat grinders produce heat; and will make the disty melt in the machine making a sticky gnarly mess.

Spend too much time in the lab and occasionally good things happen. It is just so much easier to work with. Did I see somewhere you are or were running a buch?

No I was workin on getting a little flash system last summer but decided against which I’m glad for because I am about to finish the last few touches on My custom system

That’s awesome. Iv been wanting to build a custom one as well. They could be soo much better