What volume do you need? 304 or 316ss?

For example I can do a 12 gal sized 304SS for around 30k with cartridge heater, high shear homogenizer, and the mixer system all installed.

Everything UL, with a nice panel.

Let me know what you are wanting.

We can do cartridge heaters for non-sensitive products, or full jacketing with oil heaters for items that need precise temperature controls.

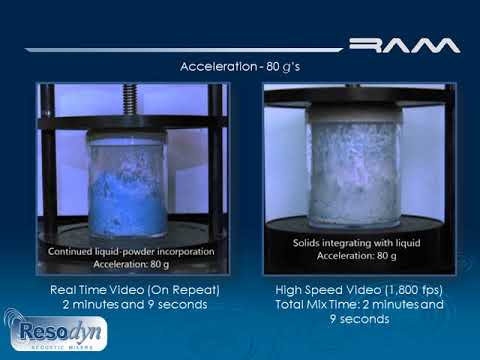

Resodyn Acoustic Mixers… check them out! Might be pricey but I recently started working with them and have enjoyed the idea that a formulation lab or facility could take advantage of what they offer. They mix by shaking containers (0.5 kilo up to 420 kg) up and down at 60Hz, and up to 100g of acceleration (can adapt for continuous flows too). Here’s a vid of a viscous paste but it works for damn near anything:

1 Like

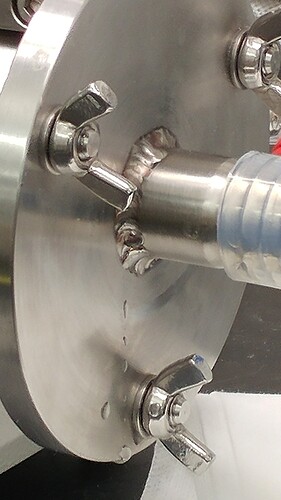

Rusted DK40 Chamber!!! Out of the box from the factory!!! Not Stainless Steel!!

DK40 Inlet Chamber: Bad Weld, Out of the box from the factory!

We were the USA CAT distributor for over 18 years. I know what I’m talking about. Ryan @goldleaf_scientific is a tire salesman, he does not. He ordered several DK40’s from the factory without knowing its limitations, he is now stuck with them and will say anything to get rid of them.

YOU MUST HAVE A SANITARY WELD APPLIED AT STEP IN THE INLET CHAMBER!!!

STAY AWAY FROM THE DK40 AT ALL COSTS!!!

1 Like

Those just have shitty welds and/or stainless steel quality. They’re not passivated/polished at all really lol

1 Like

The ones we have here are flawless. They are polished and there is no rust and the welds are really nice. Obviously if you trap moisture in there and let it sit for months then its going to get some rusting on the surface but as long as you store it and clean it then its not an issue.

This image is from

@goldleaf_scientific. He sent me this image in March, 2021, of one of his DK40’s from the factory. Look at the bottom left hand corner of the image. The inside edge of the chamber is gouged, same with the o-ring. This is out of the box from the factory. It’s junk and will leak. But don’t worry

@goldleaf_scientific will stand behind it! He’ll send you some gasket sealer and it will be good as new!!!

This is an example of @goldleaf_scientific flawless DK40 Flow-Through-Chambers.

Stay away from the DK40 and especially Ryan at Goldleaf Scientific.

1 Like

Hope you’ve find success already. But if you haven’t, at least for the lotion, why don’t you make a surfactant-cannabinoid mix with a certain PEG-based surfactant (no carrier oil needed) → melt it → add to the base lotion with constant stirring (at maximum possible speed achievable with no splattering)? Run the process in a glass vessel first, in a small batch, with an overhead stirrer, so that you can monitor the homogenization (or lack thereof). Also, calculate beforehand to ensure that the total volume of the components inside the vessel does not exceed 50% of the vessel.

They make drum mixers…If it’s viscous, you could try warming it by putting it in a warm room or using a drum wrap heater. The idea of pre homogenizing into a small amount of your base is good.

We use 5 gallon food grade buckets and a large mixer (plastic fin version) and a plug in hand drill. Some of the mixing ability and technique comes from the actual ingredients that cannabanoids are being mixed into.

Do you get uniform heating with the wrap heater? Or do you use a full-fledged heating jacket? Just curious because the latter costs quite more.

Can you share an image of the mixer? I’m very interested. You mentioned plastic. How high a temperature can it withstand?

Why would you need to go that hot? It’s actually silicone I believe so temp shouldn’t be an issue

I don’t use them for this purpose, so I don’t know for sure. You won’t get uniform heating unless you have the mixer running. I’d try to figure out how warm you have to get the base. Alot of salve bases go liquid at relatively low temperatures. I don’t know how much you want to invest up front, but you could probably get a drum of salve base liquid by putting it in a closet with a space heater, but it’d take a while. If you got the room up to 110, it’d be liquid if it was similar to the salve base I’ve used. It’s not too techinical. The more watts you can apply without overheating/smoking/burning, the faster. The better you can get that heat transferred and distributed into the entire mass of the base, the more homogenized. If you got the room up to 110, it’d be liquid if it was similar to the salve base I’ve used.

1 Like

Hey I’m looking for a white label thc:cbd (true full spectrum) wholesaler

Of topicals* specifically my bad didn’t include that