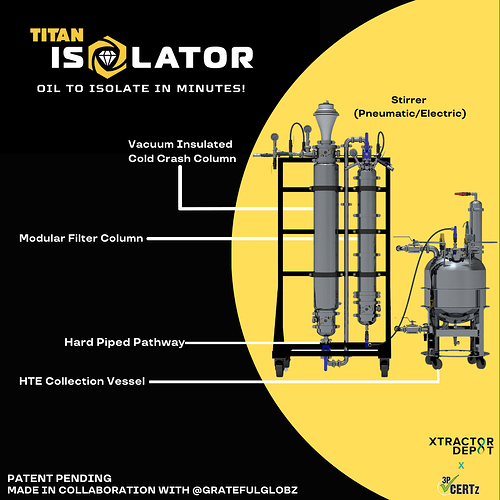

Hey guy’s! I want to share with you something i have been working on for a bit! I came up with the idea more for post processing right after runs. Especially fresh frozen runs. Doing a cold crash to preserve those monoterps you are trying to so hard to keep by freezing the material.

Also the isolate is odorless so when wanting to melt down into liquid diamonds terps wont isomerize & the decarb process can be done under vac

What are the throughput specs?

What type of thermal control is needed?

Package cost?

What psi is required for the motor? (Electric is a no-no in C1D1) what coupler and seal are you using for the shaft? What are the odds for failure and metal on metal during rotation ? Are these rated for the temperature you’re using?

Any licensed engineers willing to sign on for certification?

Not if it’s rated for c1d1. I can’t believe they make things like that, it’s crazy.

And it’s done cold, minimal to no pressure needed. But, like most extraction equipment from a largely known manufacturer. It probably has been pressure tested and has a prv or two.

What powers gas sensors, ventilation fans, Lights, and strobes? Those are just the required things you need to safely operate

You can absolutely have electric motors running pumps or stirring as long as they are rated.

Size?.. capabilities per run?

Very cool. Shows 3pCertz in the ad @EverettMarm for certification it looks.

up to 4kg of thca heavy solution more for ff. Run time is just under an hour for isolation and filtration.

Just -20c chiller to run through the jacket

all it really requires is separate housing that wont allow vapors in. how do you think the lpg industry exists? no electricity at all? everything is stainless so outside of a gasket temperature ratings are gonna be fine, so the metal on metal possibility is the only reasonable question here whatsoever. for the pneumatic side of this you should also probably be asking about the cfm and not the psi. just my .2

like 4kgs of thca in solution per run?

Why can you fit more thca if its FF?

The terps act as a solvent itself so saturation point is different

Thanks that’s what I assumed you meant, just wanted public clarification so others reading along understand as well.

What volume is each vessel?

I’ve never seen an electric drive motor C1D1, but I can only imagine the cost.

You probably havent been around many labs then. You ever seen or heard of solvent recovery pumps? More specifically a corken recovery pump? Its been around forever in the gas and chemical industry and is in far more dangerous areas than an extraction lab.

I’ve seen the belt driven pneumatic cylinder-type gas pumps.

Never seen a direct drive overhead mixer.

They’re not that expensive in extractor money.

Extractor money is kinda like boat money. $100 in boat money is like 10 regular dollars.

You win the forum today.

It’s not about the price. It’s about making it happen.

LOL thanks!

As an owner of both, neither are for someone trying to pinch pennies, that’s for sure.

this is an excellent analogy. Everyone knows boat actually stands for bust out another thousand only with labs its bust out another 10k.

Truth. My gas bill alone would finance a really nice waterfront mansion lol.