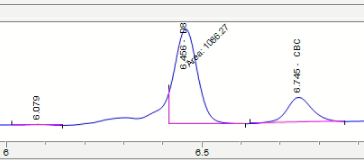

Gll gave me a “compliant” COA for this too - along with saying “There may be other laboratories that identify and integrate delta-9 THC in this sample material”

Everyone else called it ~4-6% d9

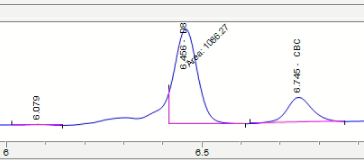

Gll gave me a “compliant” COA for this too - along with saying “There may be other laboratories that identify and integrate delta-9 THC in this sample material”

Everyone else called it ~4-6% d9