This is good advice. Sometimes it’s better to just pack the column as much as it can go and not stuff the shit out of it.

I normally fit around 2lb in it or a little less. I have always thought the amount of remaining solvent was an issue, but haven’t had too much success getting it out. Is applying a bit of nitrogen to the top of the column pretty much all I could do?

Two lb’s dry, I should add. Around 6-7FF

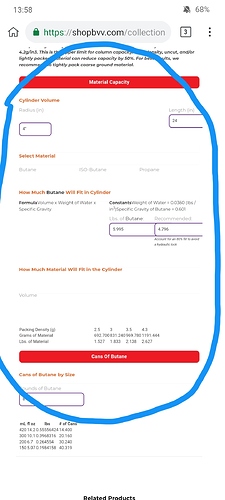

If you expand the description, there’s a volume calculator for solvent in a spool. You can plug in the pipe diameter and the length, pick type of gas, and it will give you some estimates.

Also gives a pack weight for materials too.

Bvv I know, but the tool is pretty neat.

that sounds like the appropriate loading. packing too tight can cause issues, but that doesn’t sound like where you are.

yes, pushing the column clear with N2 is a reasonable response. a hot solvent (gas phase) push is another. the advantage of the hot vapor push is you don’t have to vent it before recovery.

putting your scale under your receiver to get a measure of how much solvent you’re actually getting through (vs into) your column might get you some insight. even filling your column with water, then dropping it into your receiver and engraving “one column full” on the inside of your receiver might be informative.

54 posts were split to a new topic: Jollyrancher thin skin

2-6% is standard yield for fresh frozen. 10-30% is average for dry depending if trim or whole plant. Exceptions for both of course but the vast majority fall within these ranges.

This topic is temporarily closed for at least 4 hours due to a large number of community flags.

This topic was automatically opened after 2 days.

@KnowledgeSeth quote

The secret of health for both mind and body is not to mourn for the past, nor to worry about the future, but to live the present moment wisely and earnestly. — Buddha

Seth has been dropping some ![]() quotes lately!

quotes lately!

so have you figured it out?

I’m still under the impression that you will get better results if you chill your collection to a colder temp than your column. It should help to “pull” your solvent out of the column and into the collection. Even using a nitro push, thermodynamics don’t change.

They do call them “Laws”.

As someone who does this regularly, it makes no difference when running n2. Especially because the extract is coming in that cold, it will chill your collection.

I like to recover as soon as everything comes to my collection, so by the time I’m finished injecting, I’ve already recovered 30-50% of the solvent from the run. This drastically reduces overall run time

Was actually debating on starting the recovery while I was still injecting! Any cons to this youve noticed? It seems like it is a good idea all around for saving some time!

Update: modified my system to run bi-directional, and instead of hammering in as hard as I could, I just gave a gentle push with my body weight. This time as well I sat my solvent tank in slurry, on top of the two injection coils. I have yet to figure out a stable way to put my entire cls on a scale, and measure the amount of butane actually entering the system. To play it safe, I just ran the entire ~20lb through one column with ~3lb of FF, then recovered 90% and ran the 20lb again through the next column. All in all I ended up getting ~50g from a 2800g FF run, and 12g from a 1200g FF run, works out to 1.75% and 1% respectively. Both were trim with a little bit of lowers. Definitely slight improvement, and while the 1200g had a pretty disappointing yield, it came out quite nice imo (attached)

something is wrong. What are all your valves and how is it set up. Instead of ff weight how big are your columns?

They’re bvv full bore valves, nothin fancy. Columns are 4x24 open jacket. I’m gonna try it again today with brand new solvent and see what happens