So, I started in this industry about eight months ago, my background has always been in chemical transfer and storage and the maintenance therein, so when I found this little start-up I was intrigued in the process but to say my training, in my opinion, was extremely insufficient. With no consideration to temperature we would begin a run by chilling our solvent tank (at this time was purely n-butane) until the tank read 35-40 psi and turn off the chiller. Then running through an injection coil in a alcohol/dry ice mixture into the material column at the fastest rate possible. Once the extraction would start to drip into our collection pot, start a timer for 2m and 15s. At the mark we would switch over to the vapor side of the solvent tank and allow this to blow over as a hot loop until the material column and transfer hose connecting it to the collection pot would first build up a frost layer then thaw for the process to be complete. This mostly would result in a full collection pot but I was constantly uneasy at the unknown amount of n-butane flowing through the system. This was then recovered back into the solvent tank at 98F through a cmep which at the point of completing the hot loop could have a coil on dry ice at its outlet and the chiller turned back on to the solvent tank. Once we would pull down to 2psi we would pour and alas always black, never pleasant smelling.

This is the current system setup

60lb Solvent tank, connected to a chiller, lined out by 3/8 s.s. hose to a 6"x36" (both open jacketed and non-jacketed) material column with a screen mesh filter on a filter plate, a second filter plate which usually has either a fast or medium flow filter paper, to a hemispherical reducer that is then lined out to my collection pot by a 3/8 s.s. hose.

The collection pot is a closed jacketed 6"x36" column with a 6"x12" closed jacketed column attached to the bottom then ended with a 3/8" ball valve on the bottom. The Collection pot is then lined out to the solvent tank by a 3/8" s.s. hose, to the CMEP, then lined out to a 3"x12" column with size 4a mole siev beads (top down) lined out through a condensing coil on dry ice

The closed jacket on the collection pot is lined through a glycol warmer.

So this is how I currently run several of my processes that I have begun to question or feel like I need the fundamentals fully spelled out so I can extend this out into productive R&D. My employer is content with the output so is not accepting of the idea of an outside contracted employee conducting training and until now have resented random internet searches as an alternative. However, I stumbled across future 4200 and now have concerns on my process. This is not a spoon as I’ve read it to be called but more and check of the basic understanding I have to fully siphon through forums.

The material I receive is ground through a Lowes contraption I have made with no regrets on its performance and have actually seen a 40-50% increase in yield since I decided to do so. The consistency, I have been told as I don’t operate one, is like running material through a dry trimmer twice. Then is frozen in regular deep freezers until use.

I chill my solvent tank to -10F before a run as that is as cold as I can get it and place my injection coil in dry ice / alcohol mixture (this coil step usually happens about fifteen minutes before I start flow.)

I pack my material column moderately tight with 5lbs biomass max. This is then vacuumed down to 30mmhg with an external vacuum pump and the open jacket is then filled with dry ice. This next part concerns my CRC process.

The material column is outfitted with a fast flow filter and is lined out to the top of a 4"x12" column with a filter plate on top with a fast flow filter, I am waiting to experiment with filter felt in this filter plate then underneath contains T-5 bleaching clay, I have experimented with silica 60 and activated alumina with celite, but thought it was too expensive and my filter layers may have been out of order but that is not the discussion. I use T-5 at a rate of 5%-16% weight of biomass depending on material, this is then packed and underneath I place slow flow filter paper directly underneath the T-5 on a filter plate, then through a 1mic welded sintered disk. Which is lined out to my collection pot.

Once all is assembled and fully under vac (material column, crc and collection pot, all done individually with an external vac pump) I bleed and vapor and warm n-butane over to my collection pot from my solvent lines before I start flow into my material column. The solvent tank is regulated with N2 at 40psi and flow is started into the material column. Once the biomass is covered by solvent I start to line out to the top of my CRC. I allow the pressure to rise to 0 then slowly line out to my collection pot. The recovery pump is always on during the entire run. I allow the solvent to slowly fill my CRC and usually maintain a pressure of around ten for this part. Once I see solvent starting to flow into my collection pot I ensure the entire CRC fees evenly cold and I slowly open the bottom outlet of my CRC. Once stable flow is established I slowly start to open the inlet of my CRC to maintain a pressure of 26psi during the solvent charge. My entire collection pot will hold a charge of 32 lbs of solvent but as I said the recovery pump is always running on the collection pot. The material charge usually takes about 8 minutes to complete, this is when I switch over to blow with N2 regulated at the same 40psi. For this part I allow pressure in my CRC to increase to 30psi. The blow over takes an additional 15-20 minutes depending on the run. I was stopping flow into my collection pot as soon as I saw the flow spit and sputter for fear of bringing over additional fats and water into my collection pot but on accident allowed it to blow over until nothing was transferring over and saw no noticeable visual or shelf stability issues so I continue.

Once complete I now start heating my collection pot, temperatures vary on my end product ( shatter that has been hit hard with t-5 I recover at 96F, if I was making badder I heat up to 84F then at 5 psi I decrease to 62f before pour) My resulting product is vastly different from before, very clear, shelf stable, no nucleation issues in my ovens, and have decided on a nice light yellow as I didn’t like the look of the water clear that I got at first, also it seems to reduce the product down to it’s base terpenes which sometimes smell like hay. I have been only using the CRC filter packed for one batch but have started experimenting with stacking, I’m not sold on consistency of that yet.

I do make badder with most of my CRC products with a rule of thumb that is it takes more than 8% to obtain desired color I don’t attempt badder as it usually results in a more dry almost crumble badder.

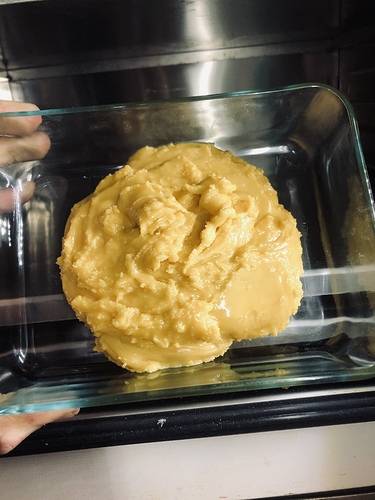

When making badder I recover as above stated but upon pour I allow the extraction to come to room temp in an oven then by placing two oven trays together to obtain an even heat, because I’m using a terrible standard stove hot plate. I whip in a pyrex dish usually for about two hours until the ribbons of color are completely homogenized. ( the hot plate is cycled on and off to achieve just above skin warm)

I then vac purge at 82F 20mmhg for 12 hours. delicious

When I make shatter my oven tek is to heat to 90F then pull vac to almost full and flip every time the slab falls or 12 hours until it stops reacting. usually about 4-6 flips

From start of solvent into the material column until I can disassemble is anywhere from 180 - 215 minutes. And due to the cold temps I lose 4lbs of solvent to my material column. I have seen silicone warming mats but am uneasy with electrical around my column or near my station.

I am unsure if I am even running the CRC efficiently and I use about 80 - 90 lbs of ice per run!!

I would like to speed my recovery but any ideas I have consist of a better heater on my collection pot (but I’ve been told he current unit is $2,700 not gonna replace) or upgrading my recovery lines to 1/2"

My material column uses 20lbs ice, my injection coil uses 3lbs ice and my condensing coil uses the rest.

Any information is appreciated but a critique would be best. Thanks in advance I will try to respond timely with questions about any incorrect terminology I may have used.