Well the thing is you can build and scale one at any size and design as long as the design follows the principal of falling film. From what I’ve read, the thing that sucks and is the most expensive part is the ancillary equipment and the heating and cooling.

Word thank you man. I love seeing designs.

As compared to a roto vap? The opposite has been my experience as the over head stirrers can move much more material much more violently but just my $0.02. Best of luck!

Pretty much. What about pulling oil out of the flask. As oil accrues on the flask it slows the solvent evaporation rate, for me anyway. I always have personally thought the ability to remove the oil from the system an integral part of maintaining a great distillation rate in a roto. Idk if others will agree.

Do you use that ecochyll thing?

What about the pressure with those things? No one is asme rated abd it seems like those would be pretty high pressure. And can you go all the way to thick crude in those things?

They seem pretty awesome don’t get me wrong, these are just the questions that I have.

That’s one of the main reasons for a stainless rotovap. Cause you could essentially just make a jacketed splatter platter with the joint on the bottom to make it rotate and have the jackets water inlet and outlet on the bottom and make it so that that’s stationary. Have a base attached to that and once it’s done spinning out just dump it out, that’s where my head was at.

That’s very interesting. Have you out the concept to paper?

No problem. I also had a mini coil going down the main pipe out of the roto ball that would act as a bump suppressant and a preheat for the injecting liquid, it then travels into a spiral around the inside of the roto bath wall then into the roto. Bath also has a little stirrer in the middle to move the heat transfer liquid around more.

The bath is what moves up and down in my design, dont need to move everything on the skid and worry about balancing ontop of a big motor lift.

I tried to draw it out but I got stuck at how I would make it so that the water inlet and outlet for the jacket would be rotational and still be functional. The only thing I can think would be having it so that the water inlet would also be able to rotate with special fittings of some sort.

And for the spinning tray it would be on to spin out the solvent would be like, you know a CD Tray on a computer how that looks when you pop it out. I was thinking something on that design but able to rotate at high speeds.

Might be better to put a CLS base on rollers in a hot water or oil bath?

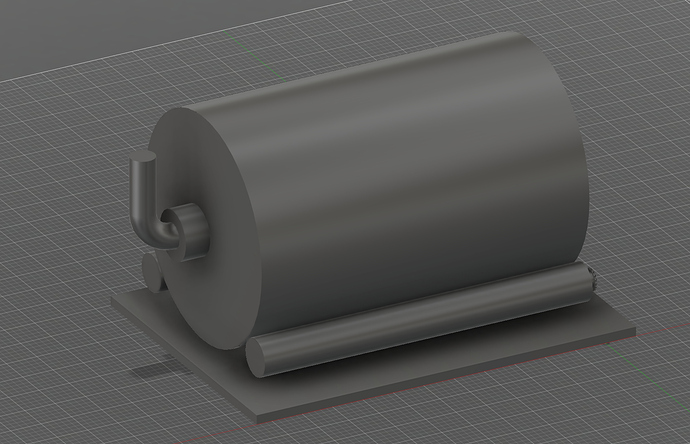

This is extremely crude, the rotary union is the collar shape on the pipe that 90s up

Lol I need to learn how to use that kind of software. What is that program?

fusion 360, free for non commercial use but they’re starting to take away features I believe

Why not just create a pot still with agitation?

Get you a 12” x 48” Base or bigger

Add a line for vacuum, nitrogen, vapor and air

Two spots for sight glasses.

A two stage condenser/cold trap. And a Recieving tank off the condenser

Idk how you’d add agitation effectively on a column that size. Seems that the CLS style drum evaporator with a custom rotary union would be the easiest way to scale.

The home distilling movement seems to be evolving in parallel to ours, there’s a lot of interesting distillation equipment popping up on the firewater subreddit that I wasn’t aware of before, seems that could offer some viable off the shelf options

They call that a still

130 gallons.

What if the rollers were heated?

Hmmmm rollers… Well what if you had a large sight glass on it? Triclamp outlet… A horizontal base… Maybe have it so you could open it up from the side and just pour it out.