Stray

July 5, 2019, 6:59pm

1

After inspection of coffee filters at bottom of material column, it is noticed that only the outer edges of the coffee filter are a yellowish color.

With the center of coffee filter a white unchanged color.

Does this sound like a sign of inefficient column packing, possibly not fully extracting center of column?

3 Likes

Stray

July 5, 2019, 7:10pm

3

Thanks, I think so.

Most columns have shown the same signs even after changes to packing density. Photo below is post extraction.

Would you say finer grind or maybe more even packing with a device that fits the 3" column better than a dowrl rod?

I’ll search for a SOP for column packing too.

judging by the crumpled filter i would assume that channelling is an issue.

get a nice filter plate, or a filter gasket for those paper filters to sit on. use a retaining ring to hold it down/push to exterior.

run more solvent through the column and/or let the column fill and wet all the surfaces inside.

what is your column size/injection line size?

2 Likes

It’s recommend doing a small if your material column has a dry ice sleeve

1 Like

Stray

July 5, 2019, 7:32pm

6

3" column diameter x 24" height. Non sleeved column.

Thanks for the advice, I will get the filter plates.

It could be channeling, it could also be the case that the edges of the paper were the lowest point and a trace of residual solvent pooled there and evaporated.Do you weigh you in going and outgoing material and chart your ballpark yields? Have you looked at the extracted tricombs under a microscope? Lastly how much solvent and material are you using, and what grade is the material?

2 Likes

Stray

July 6, 2019, 11:31pm

9

Thanks for the feedback and questions. I think you are correct.

I will need to gather data.

This does correlate to the lowest point in column so that is a plus., Residuals collecting and evaporating .

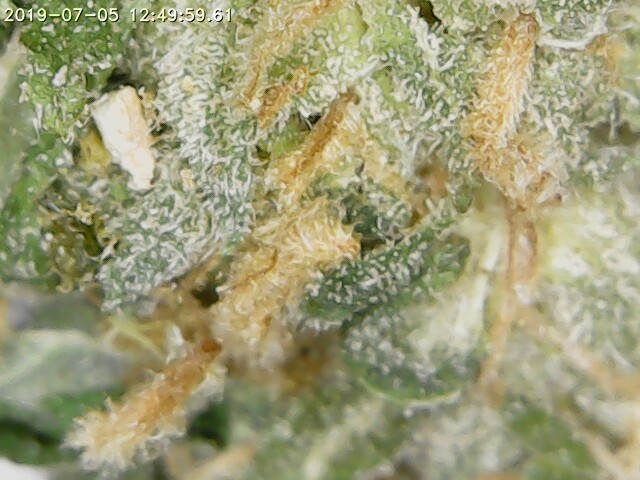

First run pic below.