All the talk of neo and Cyclo pentane and the only places I can find them are in freezers lol

Nah all the main suppliers will send to me the same gas the large companies…I’ve got 20-60-100lbs source . Tank I went on binge bought from every company while back but my gas isn’t new enough to have the issue. A client of mine recently got gas we didn’t see any issues and no were not running thousands lbs a month. I was the only extract at the time that’d take forever but we went through good many tanks gas

If the problem is taking away by distilling the gas through 13x beads then it’s obvious this is gas issue without doubt

Still blaming the lunar cycle. and Jupiter is bright is the sky!

These solvents are called refrigerants because of where they are sourced from: freezers

![]()

Our plant is dark today, extending the holiday weekend. Hope all enjoyed Christmas.

Thought I’d add a few relevant thoughts and comments.

There’s a world of difference between the hydrocarbons used as aerosols and those that we offer to the extraction industry. While aerosols are odorless, they are not high purity and fall far short of the 99.5% standard for instrument grade. We don’t offer aerosol grade hydrocarbons and cannot speak to their typical purity or what contaminates they contain.

There is no such thing as medical grade / USP hydrocarbons. Some states require that the highest purity hydrocarbon readily available grade be used for medical applications. 99.5% has always been acceptable for medical use.

Neopentane used to to be inexpensive. Used to buy it in half tons from Organic Technologies, now Wiley Organics. They no longer offer the material. I only found one chemical re-packager that offers it on-line and the pricing is not for the meek/. CAS 463-82-1.

http://www.synquestlabs.com/product/id/72024.htm

The only way nitrogen could cause this problem is if the tank is contaminated - the nitrogen gas isn’t. All nitrogen comes from Air Separation plants. At the end of processing, the gas exceeds 99.999% purity and, as it’s produced from atmosphere, the only contaminates in it are atmospheric. All grades of nitrogen come out of the same spigot. The difference in grades is determined by the testing done on the gas. If you’re skeptical, get a dewar of liquid N2 from an industrial gas facility and use that gas as it boils off in the stainless steel container. It’s 99.999% pure and has no potential container contamination.

Above BigJohnOil posted an analysis performed by Dave Balazs’ lab. Dave runs a reliable lab with the proper equipment and standards to qualify and quantify hydrocarbon contaminates. Not sure if the product shown in the above analysis was ours or from a different fill plant, but the results are typical of Diversified material. Benzene contamination is shown as “No Benzene Detected (< 1 ppm)”. While it’s true that this phrase can be taken literally at < 1 ppm Benzene, the statement itself has more meaning. “No Benzene Detected” means that there was no peak at the retention time where benzene would appear. The “<1 ppm” is not the detection limit, rather it is the LOQ, the level of quantification. It’s proper and defendable to report the contaminate as “not detected (< the LOQ)”. There is no propylene or benzene in Diversified Instrument Grade hydrocarbons.

Limits of detection and quantification are important. If a lab was to report that it tests to “parts-per-trillion”, the claim is naïve to say the least. While it’s true that if a GC-FID test is properly done, each hydrocarbon contaminate will show a peak and the peak area is calculated by the equipment and might show ppb levels, possible even ppt levels, the LOQ of the equipment dictates that such extended numbers are not reliable.

I am in the Portland/Saco area and also use cannagas. I would love to come out to your lab, shoot the shit and try and figure this out / politic. If your interested send me a dm. No charge. I have yet to see the chaulky diamonds and would love to get ahead of them.

Come down when ever. Our lab is always open

@vortal is in Maine @johnbigoilco. His comment was directed toward @dr_terpene. I wouldn’t mind checking out your spot too sometime @dr_terpene I’m near vortal.

We need to organize a new england GLG/F4200 event.

We use a tri-blend, 50/25/25, butane, propane, isobutane. And also straight n-tane. Both of them have the same issues

So it could theoretically be just the butane causing it

It’s not isobutane

Exactly, we are getting the same reactions on a lot of the jars.

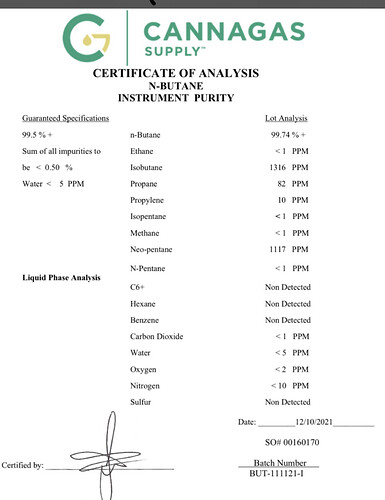

Does that coa match your tank?

It sure does

All from the same batch

Dang that seems higher than normal

Have a clue what the neo pentane usually is from them?

Probably naturally occurring in the World’s oil reserves. Like all the other LPGs.

so just got a test back from a lab I dont normally use. They said our concentrates popped for ethylene oxide. Supposedly this is used in refining hydrocarbons. No other lab has ever had our stuff fail for this. I find it interesting that none of the coa’s from the butane suppliers have ethylene oxide on them. TBH Solvent suppliers should be testing for all the solvents we fail for as producers not just the 7-9 that they currently test for.