Ok so I am in marocco and a 50L rotavape is used to recover petroleum ether 40-60 C of wich is content is at least hydrocarbons with a bp of approx 40 C the connected chillers are only capable to cool to 7 C these are connected to the glass coils 6 kw

But the delta T isindervacuum way to low and at least 30% gets pulled treu the pump I have a 16Kw chiller at -20C that I can tap from to cool a stainlessteel condensor in the vapor path but not sure wich type of condensor would suit best for this application

Choices are deplegmator 2” 4 feet long or coil diameter 22Mm submerged in -20C vessel

Both will drain by gravity in solvent catch tank

So sorry for the simple scetch hope you can imagine what’s intended

The vacuum pump on the system is 30 cfm rotary vane 2 stage

So really want to keep vapors out

@Lincoln20XX @cyclopath

What the recommendation ?

1 Like

@Lincoln20XX will need the length of that stainless coil.

I’m gonna suggest we call in @TheGratefulPhil as well.

Right now the shotgun seems good…but recall; I’m a biologist, so I guess and itterate.

1 Like

Is AND possible instead of OR?

Given no other information, I’d go with the dephlegmator, which I assume is a tube and shell/shotgun condenser.

Packing either of your condensers with some kind of packing material - stainless steel wool can work in a pinch - may make your life better.

1 Like

Pretty much always, especially when we’re talking condenser surface area.

For this application, a plate exchanger may be the simplest way to get sufficient surface area to move the bottleneck/problem to a more desirable location.

2 Likes

If AND is possible, I’d probably do coil first/closest to boiler, then shotgun after the coil.

Yes so from the glass coils there is a bridge in 2” triclamp gooing down to the collection vessel with 2” shotgun condensors where I want to place a T

With a condensor either a shotgun or a coil not sure how much a coil is gooing to affect the vacuum depth

Since it s a prettty long tube coiled up

My idea is to have the vapors pass treu the coil and cool the tank the coil is submerged in

As for the recommendation of scrubbed in the condensor pipes

It s a good idea and already implemented since the heat transfer of the scrubbed touching the metal side walls of the pipes improves their function thx

Do you think it can handel the 30cfm vacuum passing treu ?

Was under the impression they would drown quickly and ubstruct the vacuum

1 Like

Depends on if it’s sized appropriately or not. A small one would absolutely drown. a big one would probably be fine. How big your big needs to be is a good question. Something that’s got a 1" or 1.5" inlet port would probably be acceptable. This is yet another bigger is better location.

Remember that you’re only really pulling 30CFM of actual gas at atmospheric pressure. It might choke the vac pump a little on first startup - but I doubt it - and unless it’s small enough that you completely flood it it will probably be fine in operation.

I’ve never played with ether but I imagine you’d want something stainless with stainless or nickel brazing instead of copper.

A thought that’s somewhat tangential to the discussion we’re having - liquids have pretty high thermal capacities. If you can make your vapour pass through a slug of liquid - through a trap or something - there’s a good chance it will condense a lot of stuff.

Similar in theoretical concept to the yellowstone(?) system that was flogged around here at one point.

1 Like

Guess I’ll yust put the 2 options to the test should not be to hard to fix

Yust need to build a custom rack to hold the tank with coil in place

1 Like

Holy shit, I just spent the past few weeks and at least 100 hours figuring out how geometry of heat exchangers affects overall condensation.

If you’re not worried about the rate at which you recover the stuff blowing past the coils and you’re just trying to stop it from reaching the pump as a vapor, you want more friction. A long coil has significantly more friction than a tube in shell heat exchanger. So much so that it will reduce mass flow by a significant quantity.

If your goal is to condense faster, a tube-in-shell seems to work better under vacuum in my experience.

Ultimately tho, you might need to reduce your vacuum depth and add a low-temp cold trap before the pump.

10 Likes

I’m actually building a set up now to condense that will replace my current rotovap set up. Use coils, preferably 1/2" stainless coils, and run r404a or r448a through the coils. direct refrigeration. Will be more efficient and will be a true work horse.

7 Likes

That’s interesting… If you’re going to do that I guess you could use an AC or something like a walk-in freezer/refrigerator evaporator core inside of a metal box (instead of a glass one) to do the same thing a bit more efficiently.

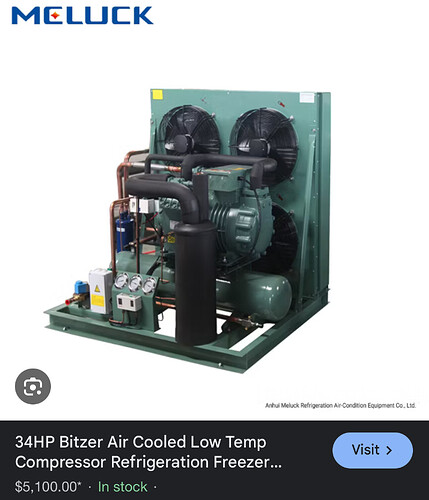

A condensing unit like the one pictured is what I’m going with. Bitzer dual stage compressor, same ones they use in the prochiller units. Run r404a (or r448a since r404a is on the outs). 34hp would smash any other units for the price, and less maintenance and risk of other components failing.

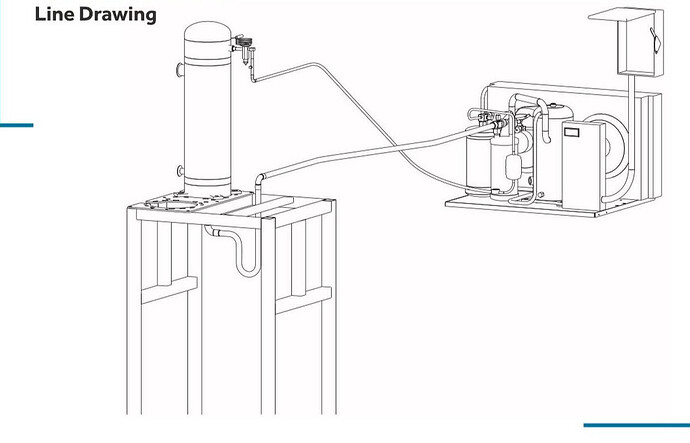

Here’s a drawing of a smaller condensing unit hooked up to a tube-n-shell. Same could be put towards coils, plate exchangers, etc.

4 Likes

Direct refrigeration is a solid suggestion.

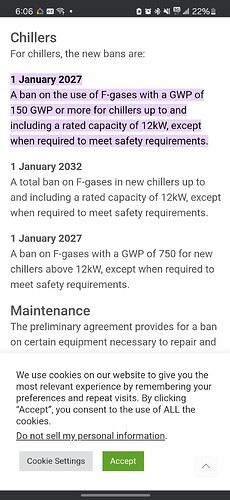

Not clear r448a is much better from a compliance standpoint…

Might as well run propane…

2 Likes

I believe that was the main thing that EcoDyst was doing that made their systems slightly less garbage than a lot of the other stuff out there.

3 Likes

BYE CHINESE F GAS BLENDS AND SHITTY CHILLERS UNTIL THEY REDESIGN.

Also @ecodyst, i think huber did direct refrigeration like that first. Ecodyst just expanded the system to include a evap flask and heater.

1 Like

Thought r448a was good. I would say 508b, but that’s on the outs too. 508b gets much colder, hard to find good condensing units for it.

1 Like