I was considering putting an impeller inside a collection pot for mixing adsorbents and butane/oil solution. My goal is to avoid a mass transfer zone, channeling, and other difficulties associated with fixed bed adsorbtion. Does anyone know of a mechanical seal which is suitable for this?

Ferrofluidic seal on eBay can be had cheap, you’ll need a cf flange most likely that can then be ported to a kf25.

this is for pressures greater than a bar?

Multiple atmospheres of pressure- they are kind of incredible devices

Interesting stuff!

This one says its “reactive gas” compatible and equipped with a KF25 flange. Unsure if it is hydrocarbon compatible, but might be an item that warrants further research:

they make a flange to triclamp adapter. i think it would be an easy retrofit to a collection pot lid.

What motor would use? Has to be explosion proof obviously but also fully sealed. I’d recommend a magnetic drive powered by a pneumatic motor

the rotary feed through would allow any means of driving the rotor, by hand even.

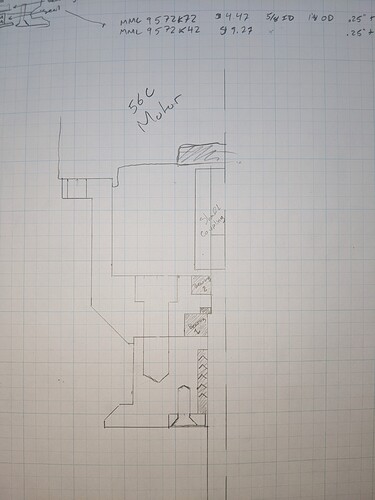

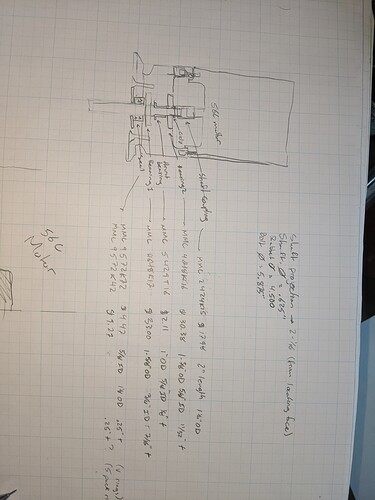

Anyone have any interest in a rotary feedthrough that’ll take max pressure on a 4" TC and fits a standard 56C motor? Thinking about having one made for a decarb reactor

what is MAX pressure?

My ferrofluid is in and the team is RARRING to go

Hard to say exactly, rotary dynamic seals are always tricky. I haven’t run FEA but I’d be pretty confident to run up to the 600 psi limitation of the clamp other than the seal might leak before then. Obviously a hydrotest would be in order before any gas service.

magnetorheological fluid sealing might be a thing here

could function both as a brake and as a seal

i need an air motor

can ferrofluidic seals really do pressure? wiki says no, logic supports it kinda

Wiki is stupid

They’re absolutely able to be rated for pressure

Ferrofluid maybe less so than MR liquid seals, but people use them a bit interchangeably as magnetorheological is a mouthful compared to ferrofluid

They are technically, not the same thing

that is very interesting. hope your adventures take off! ![]()

Yeah sealing at high pressures is funny. The “ratings” really aren’t worth shit, prototyping is really the only way to find out. Good manufacturer’s can usually recommend a solution that will work but only because they’ve done it before.

As far as using a ferrofluid coupler, I’m pretty sure it would work but I’m also cheap ![]()

Please look into magnetic couplers

Not a lot more expensive and

Way betrer ratings on all counts

Temp resistance pressure resistance

Cleaning and baking

Torque and welded on a triclamp ferulle

Very versetile

I ll try to post some links of where to buy

Also please don t forget to use

Flex couplings and cardan acels to line

It all for without the ware and tare is a lot higher