Mine do a great job of heating up evenly. FYI All designs of heat plates use the same type of heating element’s. I also noticed that Dabpress also offer’s a 10 ton ram with gauge for their press’s I highly suggest buying 1. Theirs more and more information on pressing coming out all the time and the right pressure is the key.

I have decided to buy the 10 ram with gauge and fit it to my 10 ton jack. If this works it will save me from buying a Dake 10 ton.![]() Just pulled the trigger mine should be here in 2-7 days weeee:sunglasses:

Just pulled the trigger mine should be here in 2-7 days weeee:sunglasses:

See, what I’m curious about with this is how often do you burp that?

Also, did you add any terps after that? I’m trying to avoid that. Did you just decarb using the jar method by putting it in an oven at 200 until a 1/4" of the bubbles were at the top? And when you decarb, does it stabilize the rosin to a distillate consistency?

let me know how it works. I’m excited to see

I’m positive all I have to do it unscrew the bleed off valve on the jack and screw in the quick connector and wala you have a press with a pressure gauge. However I noticed that my press is a 12 ton and not a 10 ton.

Received my 10 ton pump yesterday and I have to go to Home Depot to get a connector to connect it to my 12 ton hand jack other than that this is a solidly built pump.

Well this modification of adapting the Dabpress 10 ton hand pump to my 12 ton hand jack is basically a bust. As it was explained to me by the local hydraulic professionals after handing me 125.00 dollars worth of adapters and yet another pressure gauge to be put on the end of said adapters that they would not guarantee the accuracy of said setup and advised a hydraulic ram would be a better fit for my project. So I now await the 10 ram that Dabpress sells.

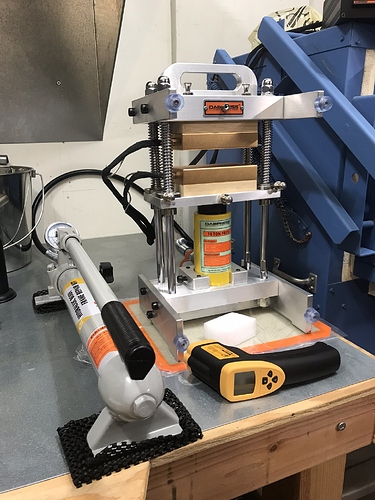

I have the dabpress 10ton all in one unit that has the driptech feature. Its a solid piece of equipment (there isn’t much going on in the design to begin with) and the price is unbeatable. You won’t find a comparable functioning unit at this price, not to mention these units look pretty sexy. My first press was the 3x5 caged plates from dabpress which I paired with a Dake B10 unit. The footprint of the machines is why I upgraded.

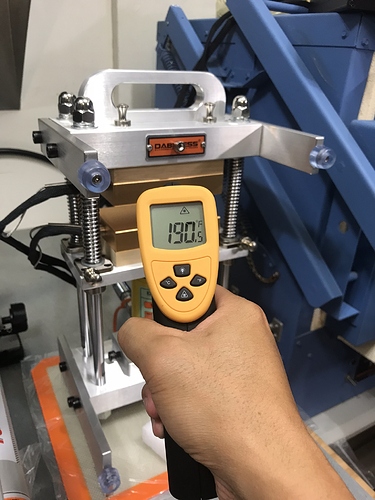

The plates reach my pressing temp of 190 in about 6 minutes and is accurate within a degree. The hand pump feels cheaper than my Dake hand pump, and doesn’t hold pressure well. I’ve been in contact with Dabpress (which has awesome customer service btw) and they are sending me a replacement pump .

Check out their website to view their product line. They have another 10ton stainless steel desktop unit that is just gorgeous for about $600, also 10 ton ram.

Ive had a set of 3x5 uncaged dabpress plates for about 4 months now, and for the price I don’t think it can be beat, even heat distribution, accurate temp readings and amazing functionality. the plates do heat up evenly and the temps displayed on the pid have never been off by more than 4° or 5°

Not all the designs are the same. Most have a heating rod going down the middle. Ive seen quite a few change it up with a custom coil that twists and turns throughout the whole plate or atleast split the heat into two rods instead of concentrating everything down the middle.

IMO the ones with the single heat rod, make for uneven heating. The edges dont ever get as hot as your middle. So if your just doing the smash and collect from the paper method. Then it works without noticing, but if you try and channel the fluid one direction, the opposite direction will have some rosin buildup that didnt make it out

Ah I haven’t seen the coil type yet. I did a quick search and found mod’s using the flat vape coils interesting concept. Now to address your single vs double heating rods. This is not IMO as I have used a heat gun to measure the temp of my 3x5 single heat rod vs my 3x7 dual rod caged plates and their is no difference in heating as both heated up evenly

When the plates have time to heat up and stabilize their temp, they might have an even heat distribution from one coil, but when u start getting into pressing and start fluctuating that temp from pressing a cold object, and repeatedly doing so back to back, your gonna get a gradient on your plates. Maybe it’s just me being too picky, but I had three temp sensors in my plates. One on the edge closest to me (I channeled the rosin one way towards me), one on the edge furthest from me, and one in the middle between the coil but not touching. Middle was always 5-10F higher then the furthest probe, and maybe 5F higher then the probe closest to me. I drilled holes and stuck a wire K type probe in each hole and stuffed SS wool behind to close up the hole and keep the wires in there.

Temps would stabilize within 1 or 2F of each other, if u let the plates sit for 10 min and let the PID do its thing.

Also my plates were 6"x6" on a 20ton press if that makes a difference

Did you bleed the line when setting up the Dabpress?

A cheap DIY way to get pressure. Fill this with hydrolic fluid and cork it with a pressure gauge. Place between ram and plate.

https://www.harborfreight.com/20-ton-hydraulic-short-body-ram-95980.html

https://www.amazon.com/LIQUID-FILLED-GAUGE-STAINLESS-CONNECTION/dp/B01NCOX9M7/ref=sr_1_3?keywords=hydraulic+pressure+gauge&qid=1568150325&s=gateway&sr=8-3

Can anyone actually answer the Question of how to Cure the rosin to go into the carts. Above was shown how but never explained… @Enzogrows

But you said you had it all figured out in your thread. Back looking for help?

You gotta delete your entire account and start over, asking nicely

$1500