I’m planning on getting a membrane system for ethanol soon and I’ve seen some people saying they still extract at -20C (or lower) even with the membrane system. I figured with membrane systems, most of the high molecular weight things that get extracted at room temperature (sugars and proteins) would be no obstacle for a membrane system. I know you need to chill to -10 to dewax properly with a membrane system, but that is pretty minimal compared to chilling to -40. Am I wrong in assuming this or is room temperature what most people are doing?

Also, a bit of context about myself.

I have a small USDA organic processing lab and I can make ~3-7 kilos a week of distillate if I really want to. The kicker is I am limited on space and capital, so I only have 1 30L chiller for running my 50L dual coil rotovap, winterize over the weekend in a tank and filter. All of this is done in a 90 sqft space where my 20L reactor (extractor) and rotovap live, my chiller and vacuum in a separate room, ethanol storage room as well. Because of my limited cooling capacity, I’m forced to do room temperature extraction and do a water wash later, (I can’t use heptane because of the organic certification so I just do it right on the crude).

Despite all of these odd limitations, I still get good results; my distillate is clear and even has a bit of a pleasant taste. I just like how I have a relatively low energy bill since I don’t do much cooling and was curious if I could continue this practice when I switch.

There is an excellent episode of The Modern Extractor, I believe it’s the first bonus episode titled “Organic Solvent Nanofiltration of Cannabis Extracts” A room temperature extraction with dewaxing is easily achieved using the correct membrane as is the case for different types of remediation, etc… This episode made me so excited honestly, some really cool tech being utilized.

@The_Modern_Extractor

@MagisterChemist

Cheers, I actually already listened to it a few months ago, and it is a great episode. I was planning on doing that, but I just wanted to make sure I wasn’t overlooking anything, like if it caused drastic throughput issues, color or odor for whatever reason.

You won’t be able to run polymer membranes at -10c

I build membrane systems

My system will be on display at the lab society booth this year at mjbizzcon

This is a 2 in 1, solvent recovery and color remediation

It made the crude I posted below

This actually isn’t true

Even some sugars make it through in ethanol

You can run the system at 5c and reject alot more then at room temp, that costs energy though

This was ethanol extract made in 110f weather this summer that I ran through the color remediation membranes

It still needed winterization, it did crash on itself after first pass without winterization though

You can tell somethings still in there

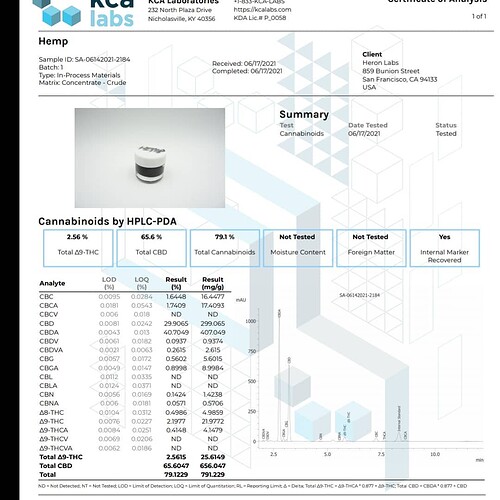

I had @kcalabs analyze my samples and they found the common plant fats and lipids were actually rejected (they got a sample for me of c7-c40 fats and ran it on MS and none popped)

Idk what it is that gets through im trying to figure it out

I think we can agree that 110f is not room temp, as well as the fact you weren’t using a dewaxing membrane. Great info to have!

Your solvent choice, membrane choice, starting material, and desired end product will influence this decision.

I am personally extracting at room temperature with membrane solvent recovery and winterization.

It can be done. Does it make sense for you to do so?

My first pass guess would be yes. But it might be no.

As with most things, “it depends” (or “more research needed, plz give funding”) is generally the answer.

We use a membrane to concentrate our solution before winterization. That way we only have to winterize 15 GPH when extracting 200-300lbs an hour. We do that in-line with less than 5kw. Then a centrifuge spins out most of our wax before filtering through DE below-40. It’s then passed through a FFE and decarb. One person can run the entire system alone. A lot of R&D went into being able to produce crude for less than $50kilo

https://www.instagram.com/p/CULYq1JjZh1/?utm_medium=copy_link

That’s funny because I have people hitting me up with x spiral systems asking me what membranes to use for Winterization

I doubt you have some top secret membrane x spiral isn’t selling its customers

I haven’t purchased anything from x-spiral. We designed and developed and built our membrane skid in house, and as far as I know we have some unique features on ours that aren’t on any other skids that are being produced right now.

We are sharing data with and working with a number of interested parties in the space.

As far as I know, we are using a different solvent matrix and likely different membranes than anyone else in the industry. [Or at least different from anyone who is talkingabout what they’re doing.]

This is my whole point, it’s you’re solvent and to expect the OP to be able to duplicate it is a stretch

You could extract with methanol then chill it to 10c and winterize with membranes, no ones doing that though

I know you’re in Canada and can get different solvents then in the US, can’t you get ethanol with methanol in it?

Huh, that’s interesting. I’m running at room temperature (25C) (my area is temperature controlled), also I’m like 10 miles from Canada, so that temperature is not applicable to me ever

.

The -10C was a number that I heard offhand from the Modern Extractor, I’m pretty sure he said you just chill the miscella to -10C so it can be winterized with a membrane. Running at 5C may not be out of the picture for extraction though. I figure the biggest variable is how much water you pull, I plan on having a molecular sieve bed before it goes into the membrane.

As for dealing with the mess, 80% cannabinoids is still great for ethanol crude. My current crude is 55% winterized and my distillate is 85-90%, so 80% with good color remediation will likely mean I don’t need to distill. But if it really does become a problem, I can run it through a short-path and just clean the flask afterwards.

Funny story, I used to not do water washes with room temp extraction and my round bottoms were charred to shit. Solid 1" of just carbon that would come out every time. Spent days of my life cleaning these flasks. Tears and flames. Now it’s better. So that’s where I’m coming from.

Membrane winterization will produce an ethanol-laden waste stream. Traditional winterization, absorbents, and water are cheaper and more efficient for producing quality oil that doesn’t need distillation, in my experience.

I’m not expecting the OP to duplicate what I’m doing. They asked a question about if something could be done, I gave an answer based on the parameters of their question. My situation is obviously different from theirs.

Probably, but that’s not an area we have explored. I believe that there is a methanol denatured ethanol on canada’s SDA list, but I haven’t had my head in those regs in a while.

There are a few ways of skinning this particular cat. You can pre-chill the input or chill the process itself. The optimal temperature will change based on your situation.

It’s just a pain in the ass to do batch processing and the speed of membrane winterization is way faster, I hate holding something at temp for 24 hrs. Also, where are you using water?

Fair enough. Also, not actually in Canada, I’m from Vermont. No, it’s a state, not a place in the Quebec Providence.

Just remember that membranes foul as they separate, and you are always better off having less shit to remove post-extraction. Your membranes will last longer if you extract colder.

This is not true, you just don’t know how to get them all through

I get all my cannabinoids through my color remediation membranes, if you buy a system I’ll show you how