checking that all this afternoon. will post pics.

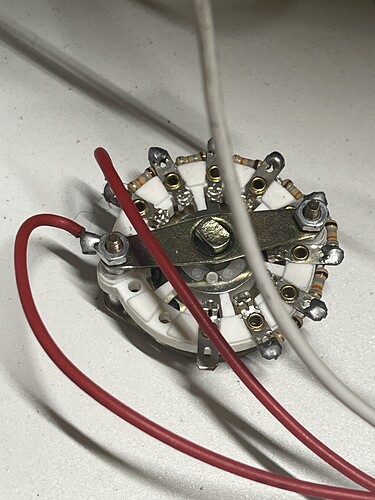

Black wire getting power. Light coming in on middle switch. Fuse has continuity. I don’t see any messed up solders. Has new carbon brushes.

So the motor is getting power and not coming on. Broken motor? Ugh chinesium

Nah, looks like it’s expired…

Did you test for power at brushes?

Can you show us what the brush/spring/contact looks like?

Not sure how to do either of those things honestly. lol. I’m guessing you mean check the lead the brush attaches to in the outside?

I have a new unit coming tomorrow but it would be nice to have two heh. I need to spin like 3000g asap

First pic is crap. But check the power there on the inside or the outside. I’m at the shop right now I can do whatever you say mr spinmaster

How hard is it to get a pair of lionballs

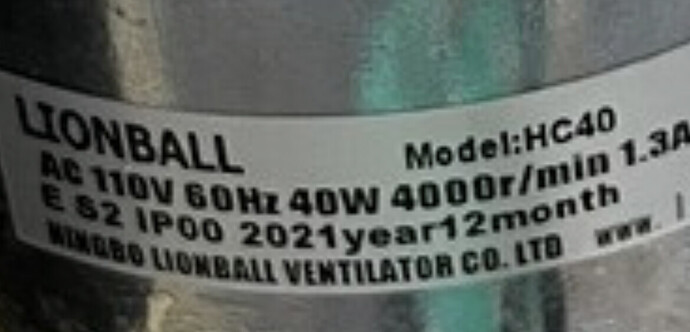

I also have this unit. Posting so I can find this thread later when mine breaks.

Looks like brush shown is hitting commutator, which presumably means they are an appropriate length.

Can you rotate motor with them in (no indicates they’re too long).

How do new brushes compare to old ones?

(Do the old ones actually look worn enough to be the issue).

As far as troubleshooting goes, having a second unit allows you to play mix & match, which is often an effective strategy.

seems to be the right size, rotates fine. i’m stumped, which i’m guessing means the motor is bad

That would be the windings. Again knowable with a meter, or a second fuge.

I don’t personally think it’s the motor, but I’ve got zero to base that on and can’t get you any further from here.

I have the second fuge. Running six pounds through it before I do anything drastic to it.

Wondering how I identify the two switches and how to order new ones. Swap those out see if it works again. I have a meter and a second working fuge. Just not sure how to check the switches or the windings. Don’t want to zap myself although I don’t see any capacitors or anything dangerous. The switches vibrate an awful lot I’m guessing the speed control switch is faulty. The new one has a speed control switch that is super loose and shakes a bit. Wondering if it shook some little cheap parts in the potentiometer loose

So this switch is definitely loose and sloppy. I’m thinking it may be the problem.

Anyone know how to identify that switch and how to order a new one? I’m guessing many others will have this same fuge and run into this issue

Wouldnt i want a 1 pole 9 position one?

that would appear to be correct, I don’t have much in the way of experience with these personally

you’ll need to figure out the resistor values as well. Have you checked the continuity and impedance through the switch/individual resistors?

I have not. I’ll look up information on how to check it.

rotary selector switch checks out, has continuity, seems to work fine.

I feel like this is something simple i’m missing now lol. there are only 5 components to this… the on off switch, the speed selector, the timer, a small very basic circuit board, and the motor. /shrug

I definately shouldn’t have quit electrical engineering school, would’ve come in handy now

Dissect that second fuge and you’ll have it figured out in no time…

I know you all have lost a lot of sleep not knowing what ever happened. I just finally ordered a third centrifuge, in case i broke the second one while i fixed the first =)

The broken one, had a broken motor. When i put it in the new centrifuge, it didn’t work, put the new one back and works fine still. I’m guessing if i could even source a new motor, it would cost about as much as a whole new centrifuge, as they are down to 145 bucks now.

Now you have some closure. lol.