Has anyone seen (and repaired or run with) this sort of damage to a wiper body?

Wiper blades are nominally spring loaded, and one blade was missing 4/5 of its springs…I’m told (haven’t got back to see it in person yet) there are metal shavings in the wiper body, but the ptfe blades are unblemished…

Not sure how to reconcile those two yet.

1 Like

I wouldn’t know how to polish the interior but I think it’s necessary to operate the system without compounding issues.

Machine shop would probably be your best bet

Not sure whether it would provide an even polish or not, but a dremel with a cotton polishing wheel might work. I’ve done a lot of polishing on motorcycles with those things

2 Likes

Pretty easy fix for any machine shop…

They make boring polishers for almost any size… if you dont care abt micron/thousandths tolerance than you can just hit it with a handheld drill and a cheap bore polisher tool.

4 Likes

Yeah, that’s the first place I went, but if I can get it chucked in a lathe I’d prefer that approach. Neither route are going to be particularly expensive.

I wouldnt lathe it.

Not worth the setup time, you wont notice a difference if its honed/polished or lathed when you’re distilling using it.

Hone/polish it using a simple attachment.

This isnt that high of a tolerance machined part. The surfaces are already brushed from OEM factory on most wipers…

The springs on the wipers compensate for any tolerance issues.

These are ‘thin film’ or ‘wiped film’ devices, there is not set film tolerance, the wipers with springs will compensate for the difference in tolerance.

4 Likes

Looks like butter knives were used as wipers! Yikes.

Hone with a brush then polishing hone should suffice.

2 Likes

Thank you to everyone who has responded.

Here and in DM.

My exact words to the client were

A cylinder hone will fix the groves, it is sourcing the springs that has proven problematic in the past.

That was before coming here. I still need to actually go see the machine in person now that they have it open.

Truth is I don’t feel like honing this myself, and the machinist I use would probably prefer to chuck it rather than use a hone. I could be wrong, and I’ll certainly point out it’s not a high tolerance job at least once.

If a hone is truly the “right” solution, we’ll get there

I don’t have an automotive machine shop on my list…

I’m also serious when I say I’ve had trouble sourcing springs.

Anyone got the spring plug?!?

Care to share?

Or even how to define the springs you have to the folks who sell them?!?

How about you @Kingofthekush420 you got a source for replacement springs for chinese wipers?

1 Like

If you exhaust all available options for buying them, I wonder if they could be custom made relatively inexpensively. This Old Tony has some good videos about spring making, and I’m curious how many machinists would feel comfortable giving it a go so long as they had the specs like wire gauge, length, spring constant, diameter, etc. I get that having to work on custom jobbies is a pita, but if you can’t buy it

2 Likes

If someone approached me about such a thing I’d be be looking for ID/OD/wire thickness, uncompressed length, compressed length, and force required to get to full compression.

That gives you enough to calculate the appropriate parameters and get at least into the right order of magnitude with a replacement.

5 Likes

I’m gonna get my boys to help me tear down our new wiper and figure out what size the blades, springs, etc are today. I can also reach out to Lab1st and see about replacement springs.

1 Like

This is the one I’m wondering how to achieve…pressing down on the appropriate scale seems like it might work.

1 Like

K = f / x

Might leverage that spring constant if it gets too tricky to get it compressed fully on the scale without skewing the result with too much mass.

1 Like

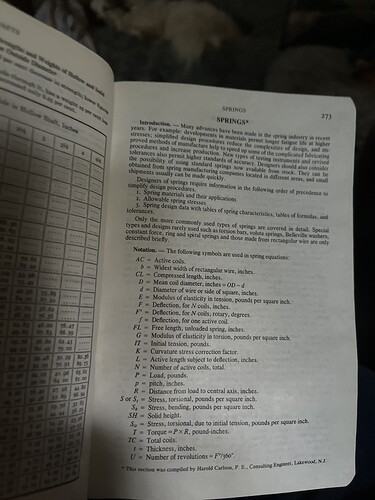

Ok, into machinery’s handbook it is…

2 Likes

Mcmaster carr has any springs you need. Take a caliper and get all dimensions.

Likely dont need the exact compression, just a spring that fits between wiper blade and the backing retainer.

Last time I looked at this, the springs we landed (from McMaster) were not a win. I dug a little and had no better luck than the owner of the still.

IIRC we were hoping to segment the blades and add more springs, so “fail” just meant we had to run it “as built”.

I think the smoke it getting to my head…

2 Likes

Are they similar to springs on electric motor brushes? I use rollers so i havent messed.with wipers much

I would assume a lathe would work best if the grooves are too deep to mechanically smooth out. Probably a much trickier execution process?