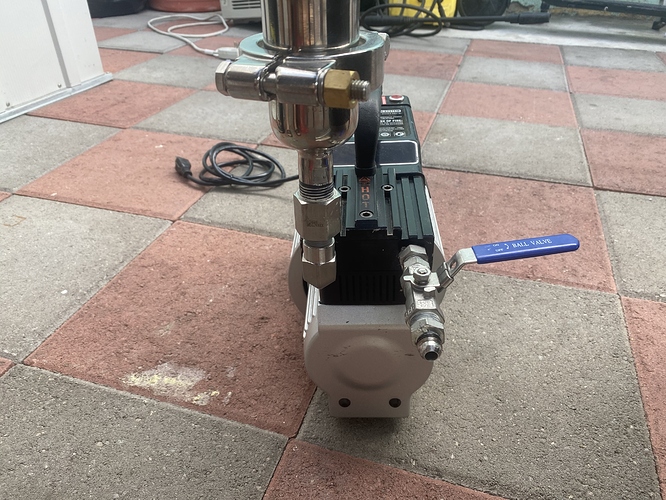

Not sure if this right topic , long time reader first time poster . But just got a steal on a trs 21 recovery pump and to my avail when I arrived they pump had already attached molecular sieve wondering if this is effective ? Change it ? Does size of the spoool for the molec matter depending on how many pounds of solvent ur running / size of system ?

It’s the amount of sieve you can fit in there and how much water it can remove, that will determine how often you have to change the beads. So it depends on your water input and how much work you want to do! As long as it’s big enough for one “run” than you can technically use it!

Open it up, and check the beads. They’re not very expensive so you can just change them out, or regenerate the ones that are currently inside. You lucked out though! Nice score! I get jealous of some of things that people score!

Sweet appreciate the input , another question . Should I leave it actually attached to the pump or have it separated I see people have double ended ball valves & ss hose on the molec sieves . And this is straight attached should that be a concern or I should be good ? Been running passive LOL , JUST switching to active , noob I know …

Right away looking at the photo I would be nervous of the stress the weight of the sieve has on the TRS21 compressor head. By removing it from the pump directly, it’ll help take stress of the compressor head, it’ll help with maintenance the pump, and having the sieve lay horizontally has proven to be more effective. As the vapor passes through, it “rolls” the beads, creating more surface area for the moisture to be caught.

If you have to take apart, it’s nice to have the valves. They tend to hold alot of butane!

Like the mis-shipped Edward’s that some dude got for free with a rotovap on here. That shit made me jealous af.

Yeah… Some things I shake my head, but others… I marvel in amazement out loud, and cuss and swear and stomp and scream inside. Only if I had the damn money… , and a modicum of luck… Maybe one day someone will give me a bunch of stuff!

Is there sealant tape on those threads? It doesn’t look like it.

Hey ya don’t know why he used a grey one will deff switch that out and make sure everything proper before use ,

I would remove it from the pump head. A heartbreak waiting to happen.

If it has mol sieve in it, you can bake it under vacuum to regenerate it a few times.

The beads are dusty and abrasive, so a good after filter is required to protect the pump if on the inlet and your tank if on the outlet.

I switched from mol sieve after the pump, to a molded zeolite filter drier in front of the pump, which both removes moisture and protects the pump from shots of liquid. Molded zeolite can also be regenerated under heat and vacuum when saturated.

Check the Mk III Evolution cyclone filter drier design. 15.30 Behold the Mk III Evolution and ancillaries - GrayWolf's Lair

I fucking love the mk3 lid. Was my first cls lid.

i switched my mole siev to the outlet of my pump because i felt it would be more consistently in vapor form due to the heat, ive recently been told this is incorrect, is on the inlet more efficient

No right answer. It is most effective and affects the pump performance the least on the discharge side. It also deposits any dust from the mol sieve in your tank, rather than run it through your pump.

On the other hand, I prefer my desiccant filter on the inlet of the pump to protect it from shot of liquid, which will wipe out the piston rings even faster.

Either way, If you are using mol sieve, you will need to dedust them and use an adequate filter. If you have an adequate filter, you will be putting restrictions on flow. Your ability to overcome restrictions on the discharge side is much greater than the intake side, where you have only 14.7 psi to work with.

I over came that by switching from mol sieve to a molded zeolite drier cartridge such as is used in the refrigeration industry, and just built my own stainless case out of sanitary fittings to house a commercial dual drier core assembly. It’s intake enters on a tangent so any liquid is sprayed against the inner shell wall rather than the cartridge.

I saw on previous comments of yours, the zeolite cart. I’m doing research on that currently. In previous work of mine we would protect the pump from debris and liquid with a small material trap with no filters just a cart with an inlet either on top or the side and outlet always on top as to not slow flow with filters and still trap debris, I have not as of yet tested this with my cmep as previously had been using much larger recovery pumps which may explain why then I had no noticeable performance loss. Either way I appreciate your reply to make sure i wasn’t having a lapse in memory with my sieve placement as I fee it captures better when at higher temps. And I have filters on both ends

LPG is only marginally water soluble, so it mostly falls out in the tank and accumulates at the bottom. If you regularly invert and vent your tank to expel any accumulated water, so it never reaches your dip tube during injection, you eliminate 99% of the issue.

I’m currently running directly out of a 100lb solvent tank but am seriously considering the benefits of having smaller one shot tanks and this is def one of them thanks for the info

This comment right here!!! Thank you for always being such an eloquent voice of reason @Graywolf

I stopped using sieve entirely when I upgraded to solvent tanks that drain from the bottom. Any water will freeze in the bottom of the tank overnight and I can drain it out the next day into a separate column or tank to filter/dry it, or more commonly, into a separate tank to burn it off outside.

This process could also be performed by freezing your gas in tall columns overnight and draining just a portion of the gas at a time to separate the heavy insoluble stuff from the rest of the solvent. This freeze & drain process will also help remove things like terpenes that can co-distill during normal runs. Using gravity+solubility via temperature = effortless cleanup.

Imo, One of the best investments a processor of any size can make is to purchase multiple solvent tanks. This will help make sure you never lose valuable processing time or risk quality to dirty gas. You can very easily transfill through sieve or gas drier cartridges from one (heated or pressurized) dirty tank into a clean tank under vacuum while the rest of your extractor is busy doing the work it was intended to do.

To expand on Murphy’ thoughts regarding multiple solvent tanks, consider buying/leasing your own supply tanks that cycle between you and your LPG supplier.

If you use the “community” tanks that the LPG supplier cycles, you are subject to the vagaries of the suppliers worst customer. Customers that pull vapor off the top and leave they mystery oil in the tank for instance.

Suppliers do their best to clean them, but consider the difficulty of doing a perfect job even with the valve removed.