Full auto ice cream machine

Bleed nitrogen outside after pushing through CRC. Pressure in recovery tank should be 0psi or lower.

I didn’t even think about him possibly not bleeding out the n2…

Did you pull a vac before filling your solvent tank? Your solvent recovery vessel should be negative pressure before opening the line.

ding ding ding!

I think @chewie has probably spotted the problem.

@Supercriticalduke; throwing a pump at that could have been disastrous…

can you confirm when/if you’re venting that N2 push?

kids do the darnedest things…

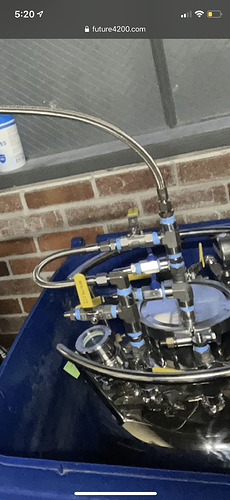

Collection left and recovery tank on right dry ice not filled ip all the way we fill pretty much to top

Not letting the n2 out immediately we push everything and then and then switch columns and do another

(Our colums only hold about 4-5 pounds material)

After we finished all 4 columns we would vent and start the boiling in collection pot

Didnt do this wasnt taught tht i think tht would help significantly

Get a bucket that fits your solvent tank a little tighter and you will be able to use less dry ice (unless you aren’t worried)

Agreed with @CokeyoDrips. Chill your tank and then pull vacuum, if it’s chilled enough it should hold vac throughout the run…

Also, where are you burping you n2 from?

What does the short “u” hose do?

Is that using the pressure in the headspace to push your columns if your solvent tank isn’t empty yet?

**@#$(*)($@#+)

guess I called that one too early ![]()

so you filled a tank with atmosphere in it?

you do vac your system down right?

you vac the solvent tank down before adding solvent for exactly the same reason. so that there is no oxygen in your system!! because: ![]()

Assuming you’re using 100% butane, then getting your solvent tank cold (-20C or below should be fine) and vacuuming that atmosphere out as @Hansel suggests is reasonably safe. a rated pump would be ideal. or maybe an aspirator on a hose outside.

I don’t however think this is the sole problem if you’ve had success on this rig in the past. it’s a issue you need to deal with, but I don’t think it’s what’s stopped you dead in the water.

if you’ve got a consult today, maybe we should stop guessing till they tell you what you missed…

but if you’re just waiting around for them to show, by all means tell us about that N2 venting process in more detail.

FYI: I ask about vacing down the system because there is a tale around here somewhere of neglecting to vac down the material columns, then using a recovery pump to pump that atmosphere into the solvent tank. it got harder and harder to recover. because more and more atmosphere was being pulled into the tank.

100 percent agree

Interested in what his consultant says about his issues…

Called it from the beginning.

You’re going to want to add a mol sieve