Thinking on the scale that I’m wanting to build (30+ gallon) a magnetic stir bar just isn’t going to cut it. I’ve got a ~150L stainless jacketed reactor that I could easily make work for this application, just need to figure out how I’m going to keep the crude moving. My decarb SOP runs under vacuum, with winter on the horizon I’d like to do everything I can keep the stink out of the building.

Curious what’s out there as far as shaft seals or ready made units to put a ~1/2" stainless shaft and prop about 20" down into my reactor. I’ve got a machine shop at my disposal but would like to start with something that has a pre-made seal/shafting section that I can add a motor and sanitary fitting to rather than fabbing the whole thing from scratch.

5 Likes

Don t under estimate magnetic stirring

I have made several stirrers from scratch capable of stirring 100 L

At a max rpm of 600

A plastic ptfe tube with 2 xxl stirbars inside make a xxxxl stirbar

A worm electro moter a bearing and 2 powerfull magnets and good to go

8 Likes

I’d be interested in pics. Trying to come up with a vacuum pot still idea and magnetic stir would be cheapest

1 Like

How large are You trying to build ?

Because the 80 liter still build i control temp treu a internal coil and agitation treu a magnetmmixer i Placed iT on

And works good enough

2 Likes

I want to use a keg for a boiling flask with a silicone heater wrap for temp control. they are 15.5 gallon or roughly 59L

2 Likes

Do You have a botom drain ? In the botom that is ?

well if i use a mag stir i wouldnt weld a bung to the bottom for drainage i would use the 1.5" triclamp shown in the pic.

Thats why i asked You Will want a botom drain to get iT all out

If You let them weld a exit tube

This tube can be used to make the axis of a magnet mixer

A bearing over the axis with a plate to screw a baseplate for the magnets on

Then the plate with magnets is belt driven to a worm electro motor

The only thing thats important is that the tube that is at the botom is valved by means of a valve that is connected by means of treads with a copper ring that is pressed to seal water tight and that legs are welded to the keg

we are building the same thing, I just sourced a rotary vacuum feedthrough for agitation.

Planned on the same drum heater for temp control.

How do you think the keg will hold up to vacuum?

2 Likes

The keg should hold up fine. Lots of ppl using them for vacuum service without issues. That bearing should work fine. I like the idea of a bulkhead type passthrough fitting vs a mag stirrer. Like rogue has said I think an not bung welded on the bottom is a must to drain the unit completely.

Now I gotta find a cheaper version of a bulkhead feed through lol that one costs as much as a new yeast brink

yeah I had to get creative with the boiling flask to make everything work.

The top of the Boiling flask has a 6" tri clamp, a 2" npt bung for sight glass, and the vac feedthrough.

The bottom has a 1/2" bung that runs to a ball valve for drain.

Im using a 4" “short path” column to a 4"x36" condenser, to a custom dry ice cold trap & then a dip tube to the bottom of the receiving vessel.

I have a 120L/min & a 30L/min diaphragm pumps, hopefully ill be able to hold decent vac depth with the 30L.

1 Like

I searched high and low, I know a magnetic stir bar would be cheaper, but the mechanical connection for $210 is worth it to me.

Ill be pairing it with a cheap eBay gear motor, 100rpm, that’s what I run my rotovap at anyway.

2 Likes

I agree I like a mixer blade vs mag stirrer I’ll probably go this same route. The yeast brinks I’m seeing cheap online are 4" TC lids with 1.5" TC bottom ports. I’ll weld up a bottom bung for a drain pickup a few elbows to make the distillation head and either find a shell and tube I can also use for the reproofing deflag or go with a big liebig

1 Like

I think the aluminum one is 210 stainless is 400

You won’t be able to use aluminum

1 Like

what’s wrong with aluminum?

The yeast brink with the 4" TC on top is nice but I wanted something I could get my arm into and clean if I ever need to. On top of my 6" tri clamp there is a 4" TC ferrule that goes directly to a 90*

I had to order (3) 4x36 condensers, they have 14 tubes in each shell. Im only planning on using two, so if you need one I have an extra.

I originally wanted a single still to produce ethanol/recover/re-proof. after some research and talking with people that have actually built vacuum stills, it is totally possible, but you need 2 different columns, and two different boiling flasks.

for ethanol production having a larger (55gal) drum seems more feasible than a 15 gal keg. also having a standard parrot setup after the condenser seems more practical to check proof during distillation. it would be a pain to break vacuum to check proof. Plus the 55gal SS drums probably can’t take that much vacuum.

I am going to do a 4x48 column filled with SPP, no defleg, condenser, parrot. this still will be purely for ethanol production.

I hit azeotrope in my rotovap every time, 43-46c with the vac running wide open, so I don’t know how much re-proofing I will need to do, hopefully I can replicate this with the vac still.

I am probably doing something similar I want at least an 85 gallon boiler pot for my reproof still I will probably make my wash in an IBC tote 275 gallons at a time 4 lowering costs

1 Like

Dissimilar metals, I should have caught that. I guess I’ll have to insulate it…

What’s your time frame for having something built?

Do you have any projected estimate on how much solvent could be recovered with a setup like this?

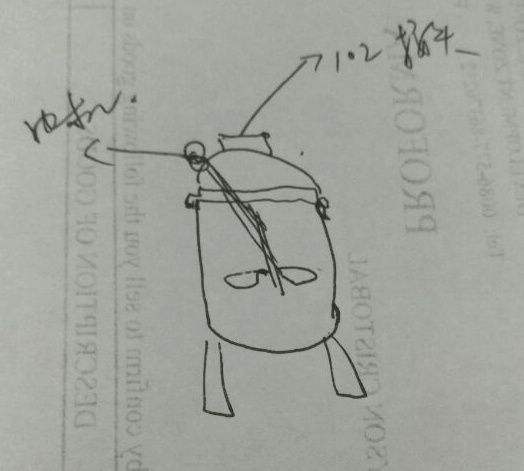

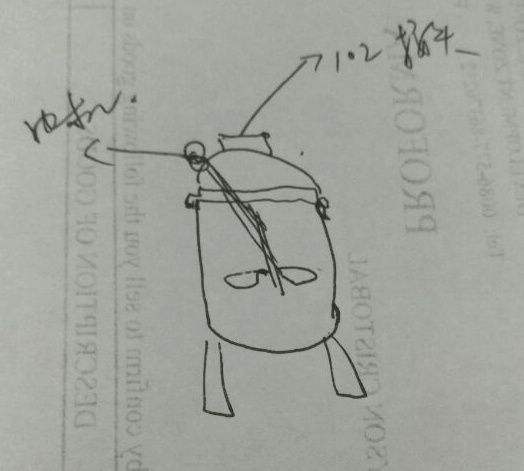

I have a quote from a china supplier for a 50L 3mm thick (for vacuum use) boiler vessel with mixer for 1k. will be a single wall and could get a custom heater wrap made for it.

2 Likes