I’m running a rather large passive closed loop with only a condenser powered by one single chiller from pro chill m series. It’s also providing thermal fluid to my solvent tank jackets. Chiller seems to not be able to cool butane fast enough. I’m assuming bc we need a cold trap powered by a separate chiller?

Implement a cross flow heat exchanger. You’ll see much better recovery times and less chilling power needed.

Giving volumes of solvent that needs recovering and specs on f chiller can give a better assessment of the problem

Chiller is a MA pro chiller and I’m recovering into 6 25 pound solvent tanks. Also using an agitator for help recovering. Chilllers Cooling Capacity to 240,674 BTU/HR. I’m recovering about 25 pounds every 10-20 min roughly.

Yeah man that’s a 70kW chiller…your setup is suffering from poor design. DM me

No way he’s running 70kW and only recovering 1lb/minute…

I’m guessing he has a 5-7kW chiller.

Looks like he is

And has 6 collections evaporating wich

At 40C do not produce more than 2 kg of butane a minute in vapor

So think he needs to make adjustments in his evaporation area and heat exchange of this area

Once he can produce the vapor things should speed up

He says he has 240,000btu yet the chiller’s website says their 24hp model is only 208,000btu at 33F…

Something isn’t adding up…

Either the chiller spec we are being told is wrong or he’s only running a few kW heater on a massive kW chiller lol… Math ain’t mathing.

Yes you’re correct I apologize. I will have to wait until I am back at the lab and I will get the model number of the chiller. Didn’t realize how many different models they offer. The chiller is massive though and I was told it should have enough cooling capability to chill well over what we’re currently using.

The easiest way to increase your recovery rate would be to increase the recovery pressure.

Which that can be done via increased heat or better evaporation method.

Higher pressure solvent needs less enthalpy (heat content) to boil/condense then the same solvent at a lower pressure for the same mass per minute evaporated.

Zack is 100% right here.

If your condenser is inappropriately designed or placed in the flow path or if you have multiple streams counteracting each other you’ll have additional issues.

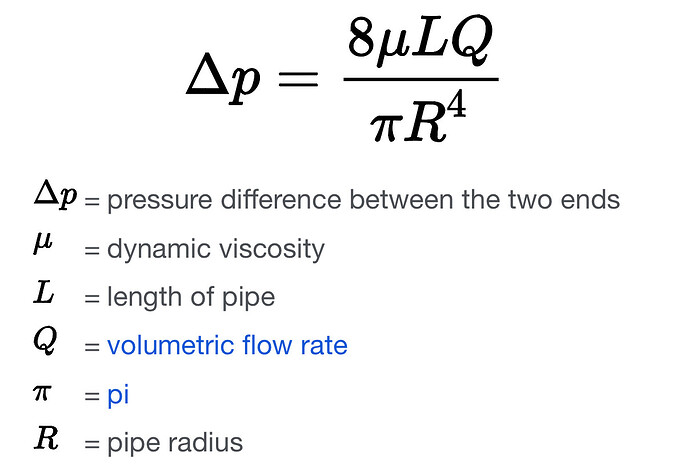

A coil will counteract your flow significantly because of the friction which impedes the mass flow. See Hagen-Poiseuille:

Just posted this in another thread but will share it here as well. Is there any calculated or quantitative proof cross flow HX’s actually reduce the amount of work needing to be preformed on either hot or cold side of the HX or is this just strictly anecdotal? I know the concept is used on large scale steam turbines but unsure if it is really effective for this use case.

It is pretty much based on my now patented heating and refrigeration technology and my pending evaporator-condenser technology. We quit using a water heater about 5 years ago. The first system we did a live demo with in California ran on nothing but a CS25 and my heating and refrigeration tech.

My tech has some specific novel requirements not on the cross flow hx that increases the efficiency of the system such that no external heating or cooling are required.

Our standard systems come rated for +50c to -50c operation. We are working on releasing the <-100c upgrade for cryogenic refrigeration. Building a -150c demo unit currently. Low power consumption with high cooling capacity, less power the colder it gets, more cooling capacity the lower the pressure becomes. The COP goes completely off the charts under -60c using just propane and one compressor.

My systems actually have made use of a simple hx for many years now to condense the hot utility vapor on the cold extraction solvent after seeing how well it worked as an evaporator-condenser. Simply defined by the mass flow through both sides at each temperature.

You can call Copeland (Emerson) America and get all the numbers they have on documentation for chilling power. You shouldn’t need a water heater like @Zack_illuminated said. I would use their Vapor cooling hot loop tech that cools the compressor and pipe that to what you’re heating. You can regulate the temp using a batch tank. Going to your heat exchanger, plumb the low and hi side and right before you hit the HX, put a TXV. Pennies on the dollar, I was quoted on a 60hp chilling option through them, that would easily take care of all my heating needs as well, for 1/3 the price of a chiller that wouldn’t do 1/2 the chilling power.