So I think I might be able to get this for 1000$. Is there anyone familiar with this model, I’ve seen talk about the smaller ones but I’m wondering if this would be to big to do 50-100g batches of carts? Also it should work well for gummies

Polytrons are solid machines. Haven’t used one in 20years, so don’t have experience using with distillate or gummies, but they will turn plant or animal tissue to liquid in seconds…

If it’s used, you might want to learn where it’s been.

I had one of those. They’re pretty finicky and easy to break, although my experience may have been because I was working with a used model. I much prefer Silverson homogenizers to polytron, those things are tanks and the R/S head design is superior.

To be honest, I prefer the “bender of death” that was designed because neither the polytron nor the tissumizer could handle the silicates in maize leaf tissue.

Even then we only got a couple or three chloroplast preps before the razor blades needed replaced.

Probably would have done a decent job at mouse smoothies too, but as a plant guy I never had to go down that road.

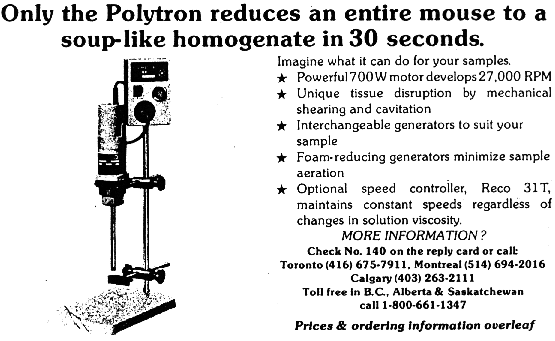

You mean reducing a mouse to a soup-like homogenate in 30 seconds?! ![]()

Indeed.

That’s why I suggest OP learn where the one they’re looking at has been

Good point lol

New strain: soupy mouse

Maybe residual mouse might be a feature?

“Natural” cannabinoid conversions

Edit: wouldn’t appease the vegans though

They told me it came from a company that made fish oil.

Swap the mouse liver for free range vegan liver

Then serve with a nice Chianti ![]()

Presumably R&D or QC.

Way too small for production.

The all knowing one has this to say

The extraction of fish oil by wet pressing is the most commonly used method for production on an industrial scale, and is basically carried out in four stages: fish cooking, pressing, decantation and centrifugation (FAO, 1986).

So the question becomes, what were they adding besides fish when they were making polytron soup? Which is probably related to “what were they looking for in their QC”.