use a switch on the imput power

Your not going to want to use the derivative control on this.

t/c= thermocouple

pid tuneing= how your pid throttles up to the setpoint, most have an autotune option.

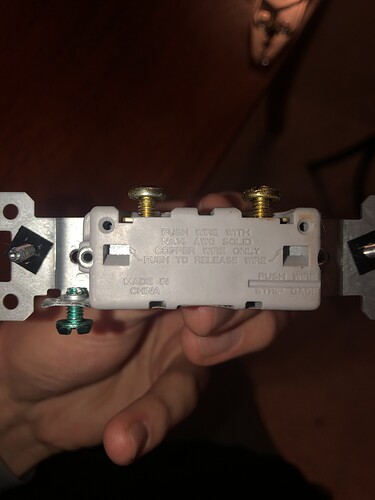

I think I have a switch somewhere, i do yea here it is

Also I recognize the abbreviation for T/C just wondering how do i tune those?

I just scanned through this post but my suggestion would be either:

Ditch that PID for a unit which has dry contacts rated for your load and voltage (ie 240v and however many amps are necessary for your heater)

Or

Use a 12v power supply with a 12v coil relay that powers your load. Honestly I stopped using SSRs for anything that’s not switched super frequently, they’re a pain to bench test and they fail much more frequently than simple guided contact power contactors. What I recommend is a relay contactor with a delay-before-make function to prevent the relay from cycling more frequently than once per 1-2s and you’ll have better luck. A plug in automotive timer relay would work perfect for this application (12v coil) if it can handle the load.

What does that mean? Like connect my heat pads to a battery?

I have a 240V pid as well

Okay so it looks like I missed the boat lol: the heater is 12v and the PID has a powered output (not just a dry contact)? Do you have a 120vac to 12vdc power supply?

My SSR(It says Solid State Module)is 3 ~ 32VDC, and 24 ~ 380VAC

Don’t do that!!

You power the SSR by plugging the PID into the wall.

Ohhhhhhhhh.

So what do I connect these to?

AH HA! I saw a video where dude had a cord with a plug that he connected to it.

The power INPUT to the 12V power supply you don’t have.

That video shows NOTHING connected to those terminals.

If you get “he plugged them into the wall” from that video, you should stop and re-evaluate your ability to solve this one.

Check out the cart farmer and the size heating pad used on the reservoir.

I suspect 12W is still a hair on the small side.

Might be but saw a guy connect a heat pad, same exact one i have, to a 12V battery then a wall plug and they both heated enough for distillate to stay homogeneous.

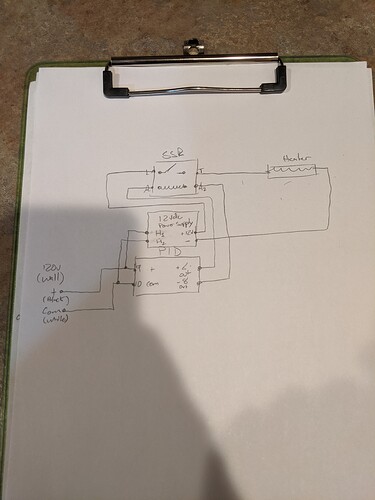

Because the output on that PID isn’t rated for enough current to drive the heater, you will need an additional 12v power supply. It’ll look like this (sorry for the messy diagram):

Heating has very little to do with homogeneity…

You’re heating to achieve the desired viscosity (lowered by heating).

You could skip the power supply and use a car battery on the right side of the “12vdc power supply” in my diagram. It will probably draw down fairly quickly

Also another thing that’s gonna be a problem for you: that SSR is rated for a minimum input of 24vdc. With an SSR (not regular relays) it will likely leak enough voltage to be a real problem if you’re only running 12v. Your easiest bet might just be some 120v heat tape/heat pad. Then you have everything you need and honestly 12W is gonna be tough for what you want

The heat strip shown doesn’t specify AC or DC, so I infer DC.

12V @ 12 w is only one amp, which seems loooooow for a resistance heater…??? What is it heating?

The SSR shown won’t switch DC, so if he is going to use a 12V heater, he can only switch the 120VAC to 12VDC power supply on and off.

It would be ostensibly cheaper to purchase a 120VAC heater but a 12VDC 1 amp transformer is about wall wart size…

Exactly…

Yes to keep it liquid and prevent homogenization my bad for term mixup, had to look back at a thread someone linked a gif comparing viscous to homogeneous and said distillate is homogeneous. My goal is to keep the chamber of the cart gun with the distillate in it warm so it doesn’t clog up and gunk up to keep it consistent and less cleaning.