Check out thermodynamics. Its cool stuff.

Show me a chiller as reliable as 2 trs21s for the same price or even near the price capable of chilling a 12x40 tank and collection pot. We have been looking.

Nitrogen is just for psi 60 to 90 is hard to push from a warm tank

The confusing part is that temperature and pressure effects are inextricably linked. A higher temperature will also increase the amount of vapor in your vessel, creating a pressure differential as well.

The reason why only using pressure won’t get you all of the butane is because you still need a pressure differential to (efficiently) move solvent vapor from one tank to the other. Think of pressure as the “amount” of vapor in your tank. As it transfers from one tank to the other, you’re increasing the pressure in your recieving tank and decreasing your pressure in the original tank. Eventually they will reach equilibrium and transfer stops happening. You can’t remove all the butane in your original tank because that would take the “pressure” to zero and you can’t create a pressure differential relative to zero Edit: without some extra help from pumps.

Yeah the main issue I was having was not remembering that the liquid still has vapor pressure, tis why I said what I did about melting point as Im pretty sure if we froze the butane in the low side the high side would, eventually, get down to the initially attained psig, correct?

Thanks for the lessons MrRandy and mcpikeig, it was late and I was tired is my excuse.

So still to drag this on, what if we had some other gas with lower bp to help knock around the remaining butane, if we add some warm propane or n2 gas through the material column when recovery of butane is slowing/stalling? In terms of function Im not a fan, but in terms of physics or thermodynamics it would work no?

More to the practicality side of it, in terms of active vs passive, if we only really start to stall and slow with passive once we have recovered the lions share of solvent and can achieve much faster than normal recovery rates with passive when there is say 10-30psig, why not only use a pump for the last remaining couple pounds of solvent if you want a fully evacuated system at the end of it?

I know my tr21 can go from -10psig to -22.5psig in a minute or two, but takes 2 hours to recover 20-25lbs. If I can recover the 20-25lbs passively as fast as 4-10minutes and then switch the pump on for 2 minutes Im looking at 10m’ish total recovery time, I can do a days worth of work in an hour and only run my pump for 10m/day total, vs 6-10h/day, assuming the desire or need to fully evacuate.

Best of both worlds?

@Roguelab

Thanks! Still think I’ll start off with a hot butane push, maybe mix in some propane.

Thoughts?

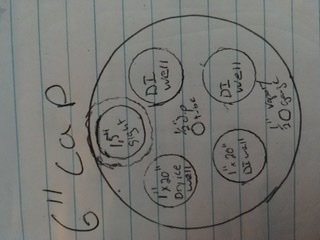

Lid for recovery tank.

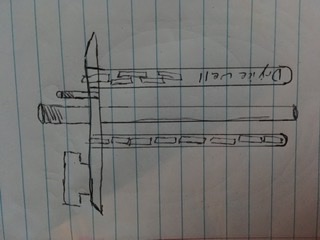

Recover through diptube using cold solvent as the condensing surface for the returning vapor.

Pro: Cold finger surface area is fully utilized

Con: A lot less surface area compared to outside jacket style.

It’ll work, is it the most efficient I dunno, if its just spare type parts why not, but if your designing a condenser specifically for the job I would assume there could be a better design.

For comparison, a 0.5" x 100’ coil has a lateral surface area of 1884sqin, your tubes have 251sqin

It would be a waste of effort compared to a better heat exchanger before solvent reaches that vessel.

Recovery through Injection coil you guys are the best. That’s why I’m here. Thanks.

@Relaxedextracts Recovery rate is determined mostly by vapor generation (evaporation rate) in the collection pot and has nothing to do with whether the system is active or passive, unless the recovery path of choice presents a bottleneck or is undersized.

You get a 5-6# per minute recovery rate by being able to heat and evaporate 5-6# per minute of solvent from your very cold and auto-refrigerating LPG/oil solution.

A lot of people, like yourself, who are just now switching to hydrocarbon extraction often under size the pump for their active recovery setup. This is something that is perpetuated by the companies selling the equipment to you. The pumps that are marketed toward the smaller extraction systems, namely the CMEPOL and TRS21, have a very small pumping capacity and in most cases, require that you use multiple pumps to avoid a bottleneck.

The pump market for small extractor setups has been pretty dismal for years and I really only recommend the TR21’s. From the beginning, pump manufacturers have avoided outright embracing the extraction industry and providing what we need so options have remained limited. Some people here may remember the old Appion and Caresaver days, lol.

The CMEPOL you have was born out of that lack of options. IMO, this pump was rushed to market around 2015 when demand was very high and it still has the same drawbacks it had then, a small pumping capacity and inadequate piston and piston ring design that allows gas to leak into the crankcase. The company hasn’t really revised the design much because everybody seems happy just selling the shit as-is to people like you who don’t really know. $2400 for that thing is absolutely crazy. I believe the displacement is only about 1.25cfm. That is really terrible.

I’m going to bump the most active Active vs Passive thread we had going, try to keep the conversation over there so we don’t get multiple threads on the same topic over and over. Also look at the trs21 vs cmepol vs passive thread for more info.

@pangea I have been really wondering about why people use N2 and whether it has something to do with passive not playing well with a warm vapor assist. The topic came up in the nitrogen vapor assist thread awhile ago, I’m going to bump that topic and respond to you there.

@downtheterphole IMO, one of the major drawbacks of larger batch passive systems is needing to keep the entire mass of solvent on the recovery side chilled low enough to not hinder the process. Can you imagine the headache of trying to keep a 50,000-100,000 gallon+ receiving tank at a cold enough deltaT to receive train car loads in a timely fashion? You are really reaching at straws here suggesting anyone would consider this type of transfer at industrial scale.

My experience based knowledge is also telling me that you’re incorrect in saying a warm vapor pressure assist will increase the extraction of undesirables. I will bump the thread we have going on the subject and respond to you there.

FWIW, here is a quick 1 minute Youtube video on how LPG train cars are actually unloaded (both liquid and vapor) using Blacker pumps and some of those “foolish” pistons, lol. It’s actually kinda interesting and they even use a similar concept you all over at Yellowstone Extraction by bubbling the incoming liquid/vapor through the cooler liquid pool of the receiving tank.

How do you remove it for recovery?

how many square i ches of solvent already at or below BP do you assume one gas bubble encounters ?? I would reccon a whole lot… This also isolates the pressure of your recovery tank from the pressure of your reactor in that they will not be connected on the same vapor circuit if that makes sense

one gas bubble encounters as it percolate up through the pool of liquid**

What model blackmer would you recommend for hydrocarbon recovery?

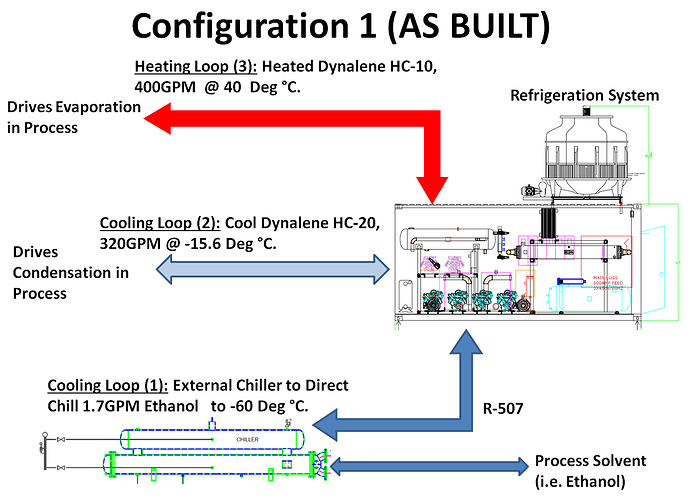

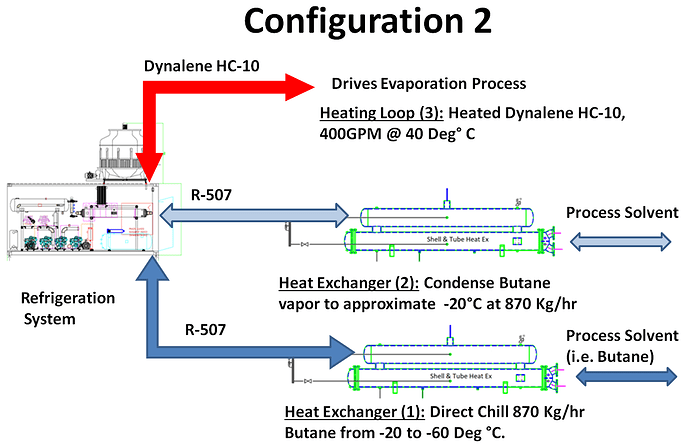

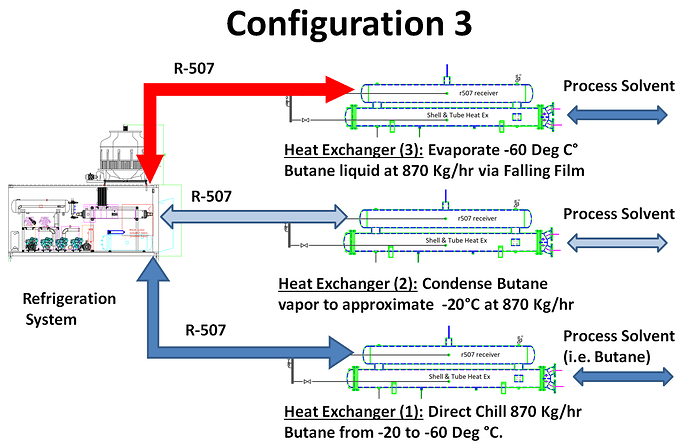

We have a system which was built for ethanol cooling, which could be easily adapted to butane:

https://www.greenprocess.solutions/wp-content/uploads/2020/05/42_Ton_R507_2Stage_Piston-1.pdf

https://www.greenprocess.solutions/?page_id=214

Not cheap obviously, but if you want the cleanest possible large scale passive process this is the only way to go, no moving parts aside from the valves and solvent.

!

how many btu/hr available on each line?

1/2" lines and appropriate vapor production as well as proper chilling capabilities.

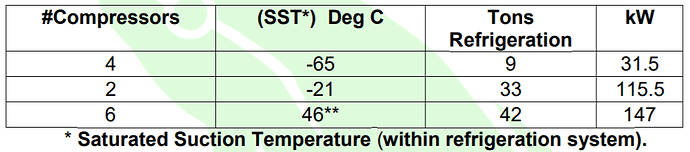

1 ton = 12,000 BTU/h = 3.5 kW

from the spec sheet.

the third loop recycles the heat generated from the other two, alternatively if no cooling load is present on the heated loop the heat is rejected via cooling tower.

https://www.greenprocess.solutions/wp-content/uploads/2020/05/42_Ton_R507_2Stage_Piston-1.pdf

I’ll take the 31.5kw of cooling at -65c, final answer.

What piece of equipment are you referring to? I’m looking for a monster chiller right now