I want to be trained how to weld ^>^ that shit is so worth knowing.

Do what I did: buy a welder and weld until you’re good lol

This is what I’m about to do lol

And have a buddy who welds for a living (and loves free oil) show me the ropes when he has time…

No substitute for practice. It helps to have someone give you a couple tips just to show you what you’re looking for. Then grab some pipe and get to work. When you’re confident in your open root 6g, send it to a testing company and have them pull it.

Welding is something I definitely want to get into myself… I’ve been thinking about it for a year, or two. I have experience working with hot air re-work stations for soldering up pcb’s/etc

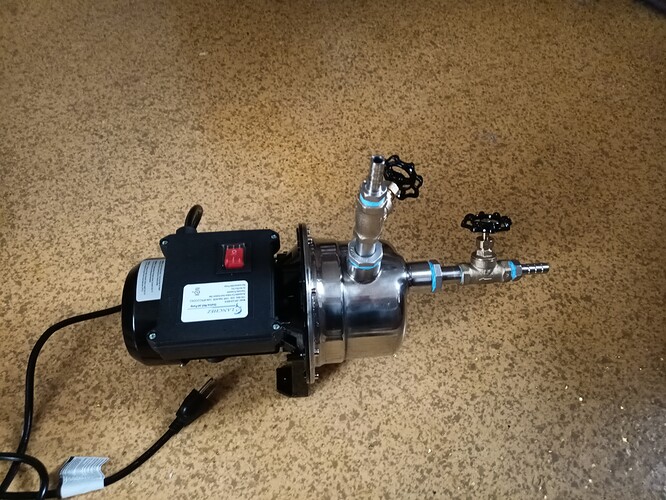

Globe valves on a stainless water transfer pump that has a stainless impeller. Full flow control

Just put the globe valves on today and tested them. It’s so fucking sick!!!

FUCK SUBMERSIBLES!!!

Because I use like 4 lbs of salt with 3lbs of dry ice the submersibles just shit out after a while because of too much salt. This thing just says whatever and moves the water

If you can, only restrict the outlet and your pump will thank you. Restricting the inlet can cause cavitation from the low pressure in the impeller and it will potentially hurt the seals

Out feed is truly all that needs it. Arent jet pumps solid? Had to thaw mine out because water froze inside it. She’s purring again

I tested it with dry ice/super salt water last week but didn’t have the valves to control the flow. No freezing issues.

I had the inlet open all the way and tried to regulate only the outlet and i was getting some flow issues. I got a more steady flow regulating both.

Edit: you’re right; though, I do feel more safe regulating both the input and output as it starts up.

It’s not really a big deal, certainly not a safety issue just a little pump general knowledge.

On another note, she RIPS. Only ran for about 15 minutes tonight, have a few good vacuum leaks to fix still but we clocked around 40 lph. We’ll see if it’ll do 60 when the leaks are fixed and the feed is preheated

UPDATE: on the pump. Believe it or not it heats up the water. I think I should just look into a glycol pump by now.

What kind of chill capacity you got going to the setup?

I think im gonna go with something like this. Definitely gonna find something cheaper though.

The grey schedule 80 pipe overhead goes to our central chilled water plant which is 215 tons. It’s only a 1-1/2 pipe into the lab though so somewhere around 30-40 ton capacity split between this and the rest of the lab

Any pump is going to add heat to the working fluid, it’s an optimization. Typically centrifugal pumps are around 70% efficient (there’s a really wide range depending on a bunch of factors), which means 30% of the electrical draw of your pump might as well be a heater. Bigger pump means more heat but it also means better turbulent flow and delta-t which make for better heat transfer.

What would you suggest doing to counter the heat from the water pump?

Only two options there: smaller pump or more ice

you know they went through the ceiling, and then the roof with their FFE out in Yerrington…

The good news is that we have 24 feet to the bottom of the next floor above that drop ceiling. The bad news is that the floor is 18" thick concrete…

On another note for those who may be watching, we kinda goofed. The vapor holdup is insane. I think I’m going to spin the whole unit so the vapor feeds from the top of the condenser which should have been a very obvious thing to do. Oh well.